Electronic control method of variable gas inlet and exhaust system of compression ignition engine

A technology of electronic control and electronic control unit, applied in electrical control, engine control, non-mechanical actuated valves, etc., can solve the inevitable problems of high emissions of soot and NOx, reduce harmful products, reduce manufacturing costs, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] What the prototype of the present invention selects is the Landking WP12.480 heavy-duty diesel engine of Weichai Power Co., Ltd.

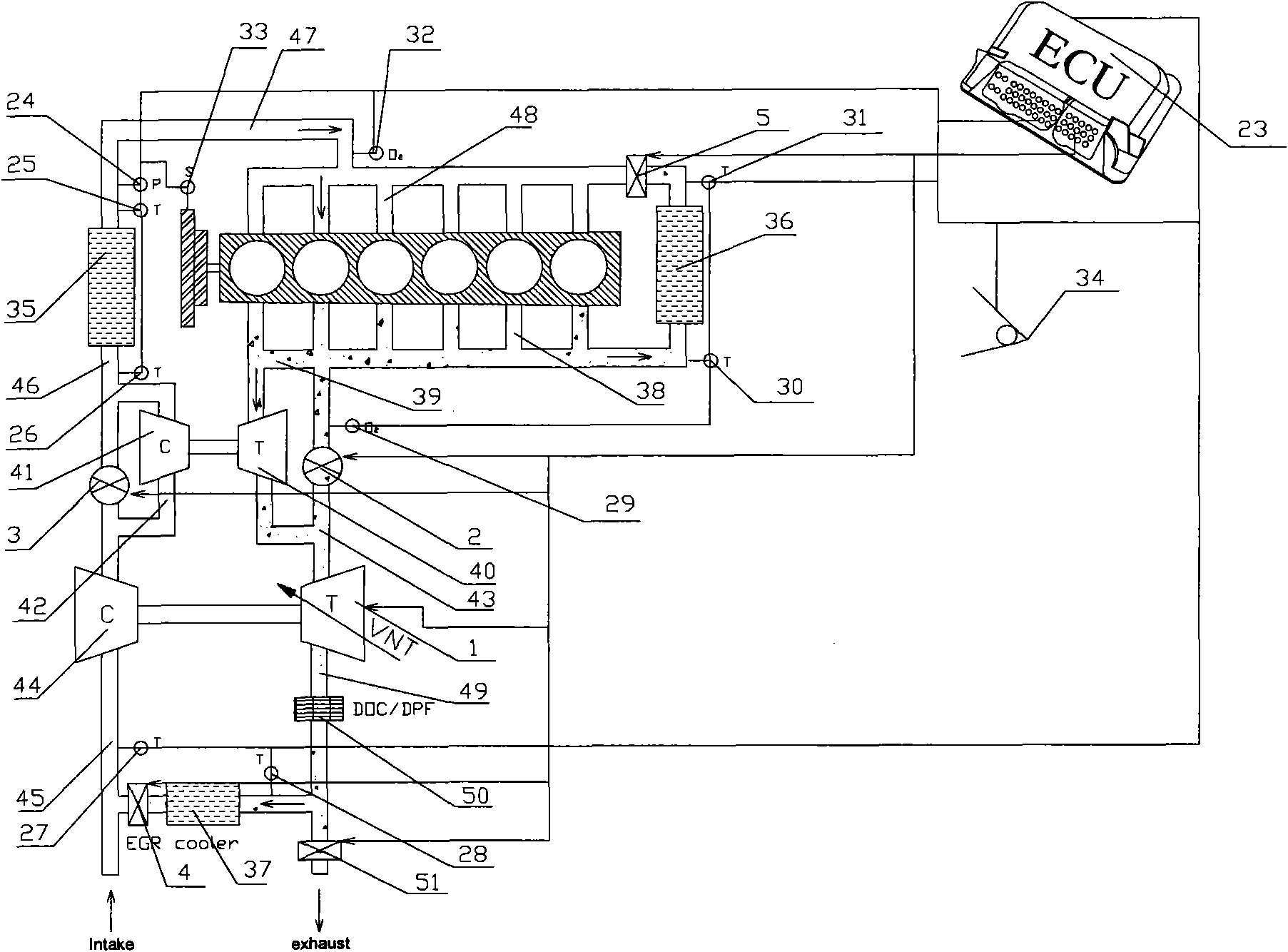

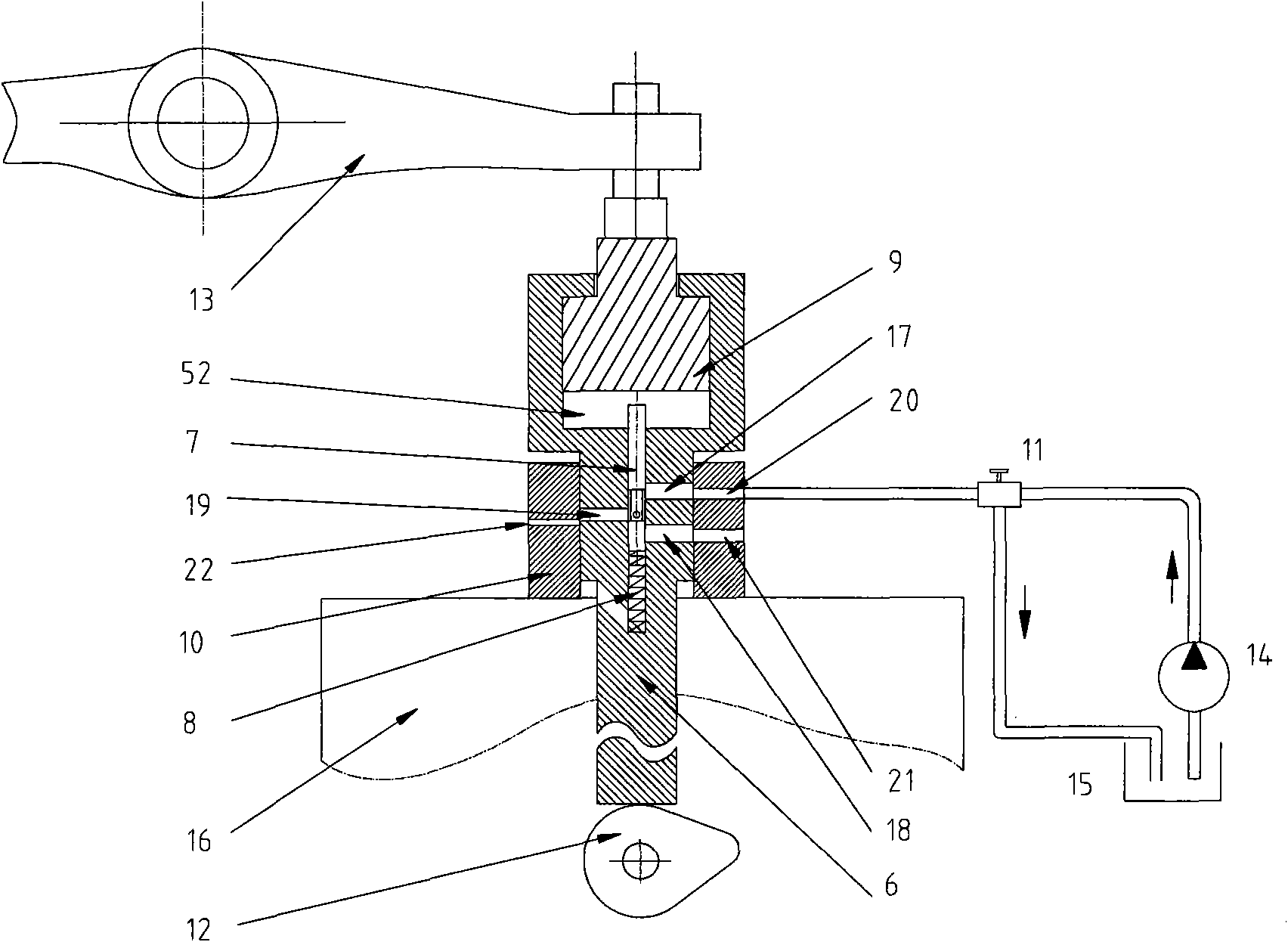

[0017]The electronic control method of the intake and exhaust system of the compression ignition internal combustion engine is composed of a supercharging system, an exhaust gas recirculation system, an intake valve late closing mechanism and an electronic control system; the supercharging system adopts a two-stage turbocharger, the first The variable turbocharger 1 is used in the first stage. According to the different target density requirements of the internal combustion engine, the section of the turbine nozzle ring can be controlled to change the intake pressure. At the same time, the opening and closing of the bypass valves 2 and 3 at both ends of the turbine and compressor can realize Intake low pressure and high pressure conversion; exhaust gas recirculation system includes high-pressure exhaust gas recirculation system and low-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com