Rolling bearing high-efficiency anti-rust oil spraying device

A spraying device and technology for rolling bearings, which is applied in the field of high-efficiency spraying devices for anti-rust oil for rolling bearings, can solve the problems of uneven spraying, complicated operation, and slow spraying speed, and achieve the effects of uniform spraying, simple operation, and fast spraying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

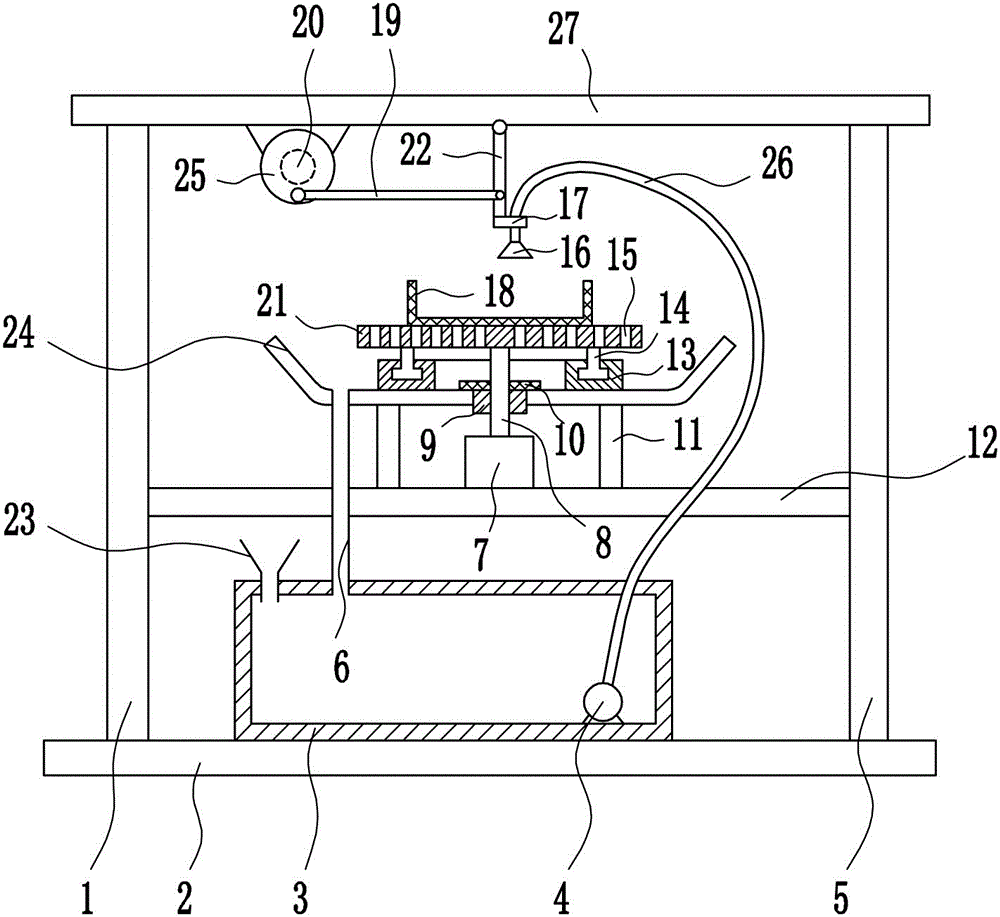

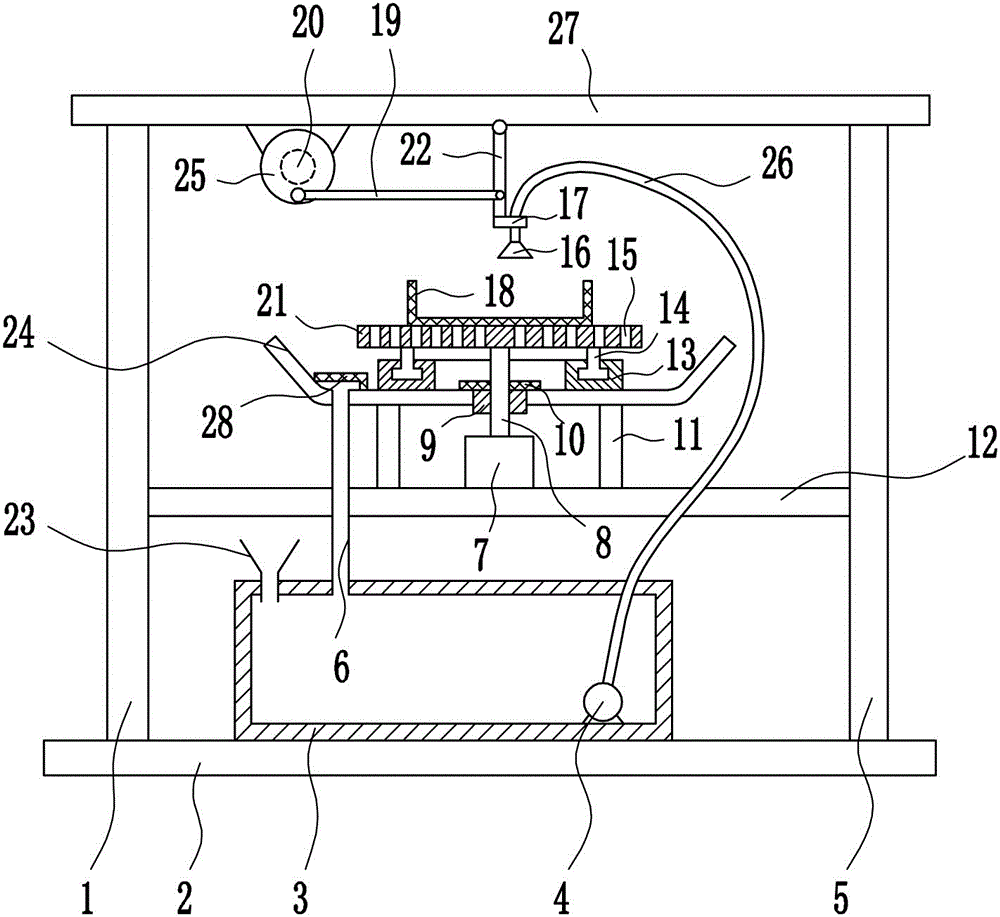

[0018] A high-efficiency spraying device for rolling bearing anti-rust oil, such as Figure 1-2 As shown, it includes left frame 1, bottom plate 2, fuel tank 3, oil pump 4, right frame 5, oil return pipe 6, motor I7, rotating shaft 8, bearing seat 9, sealing ring 10, support rod 11, fixed plate 12, annular slide Rail 13, slider 14, nozzle 16, fastening sleeve 17, screen frame 18, connecting rod 19, motor II 20, spraying rotary plate 21, pendulum rod 22, oil inlet hopper 23, spraying disc 24, turntable 25, hose 26 And the top plate 27, the top of the bottom plate 2 is provided with the left frame 1, the fuel tank 3 and the right frame 5 successively from left to right, the oil pump 4 is arranged on the right side of the inner bottom of the fuel tank 3, and the oil pump 4 is provided with a hose 26, and the hose 26 passes through The top of the fuel tank 3 is provided with an oil inlet bucket 23 on the left side of the top of the fuel tank 3, and a fixed plate 12 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com