Fuel injection rule measuring device of diesel engine and measuring method thereof

A technology of fuel injection rule and measuring device, which is applied in the field of measuring device of diesel engine fuel injection regularity, can solve the problems of decreased measurement accuracy, high price of a single injection measurement system, etc., and achieves the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

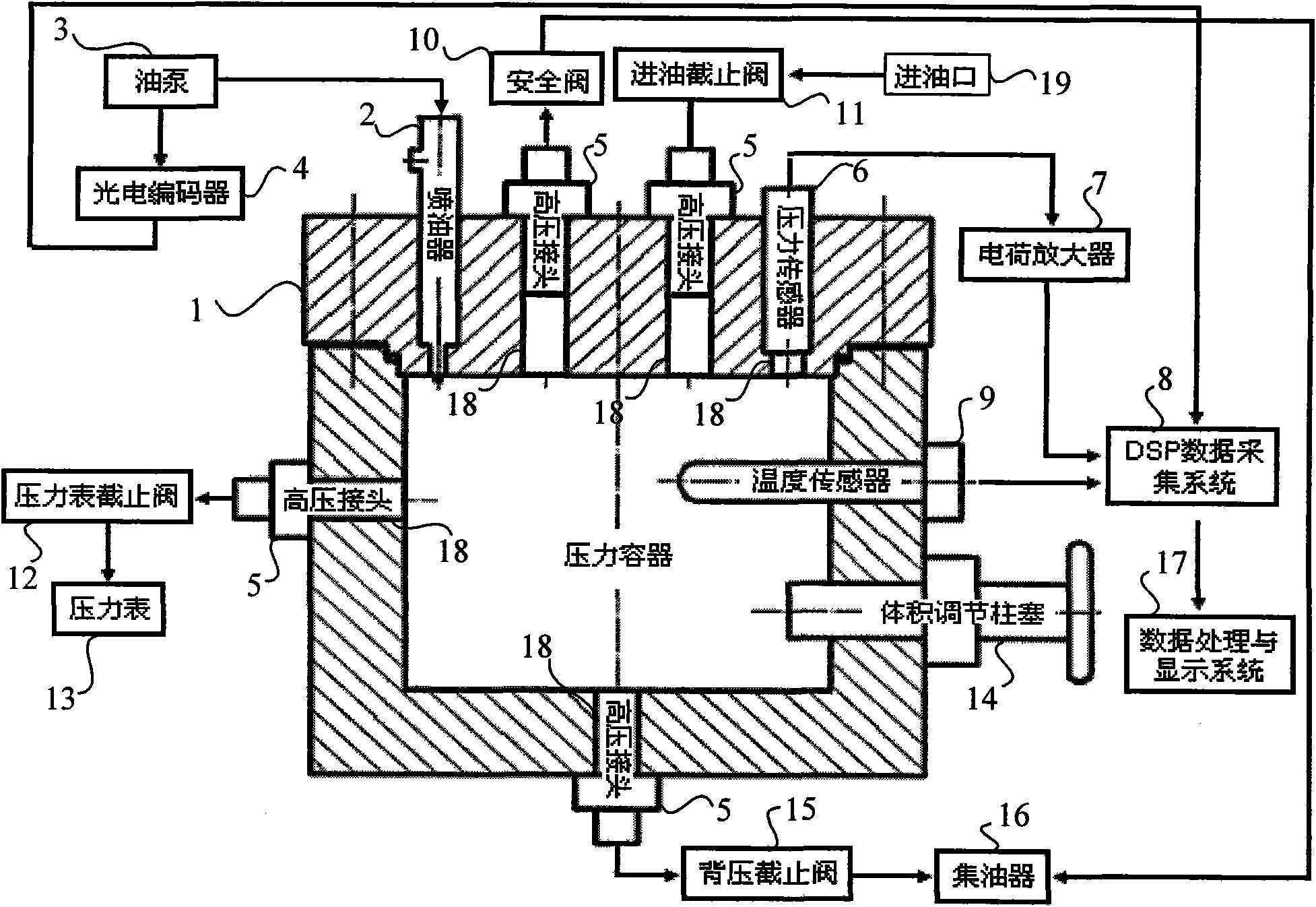

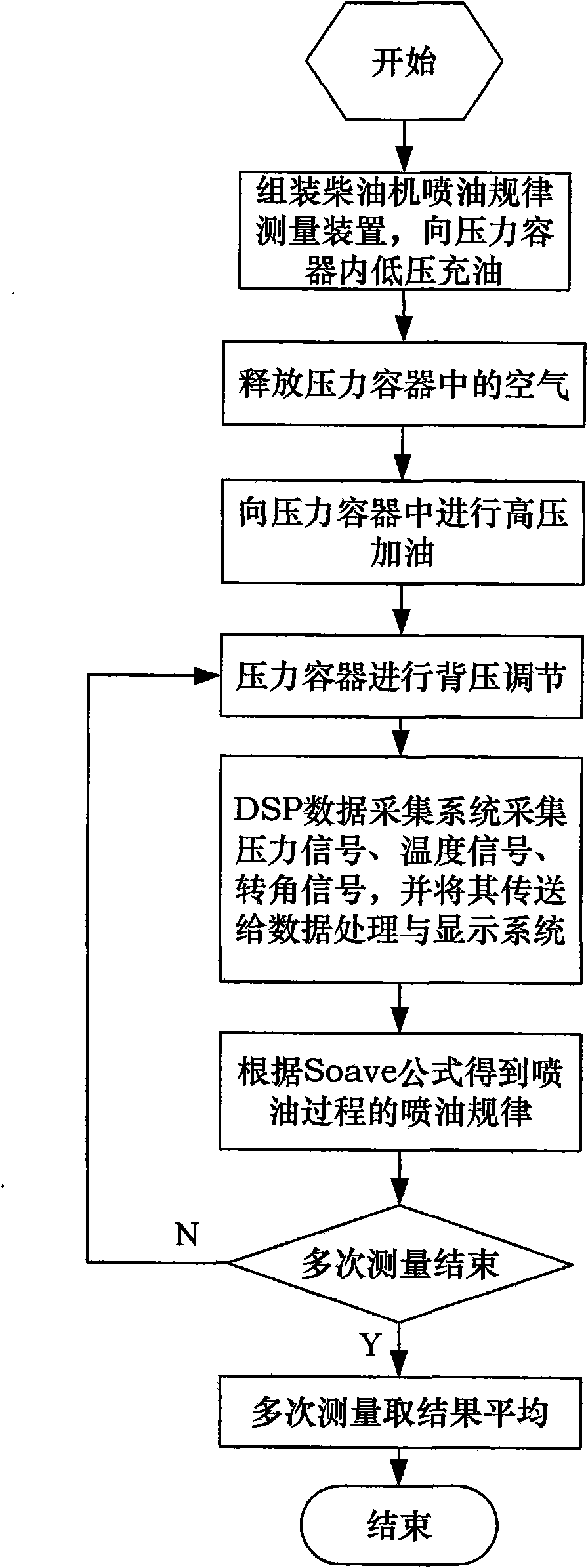

[0031] The present invention is a diesel engine fuel injection rule measurement device, such as figure 1 As shown, it includes pressure vessel 1, fuel injector 2, oil pump 3, photoelectric encoder 4, high pressure joint 5, pressure sensor 6, charge amplifier 7, DSP data acquisition system 8, temperature sensor 9, safety valve 10, oil inlet cut-off Valve 11, pressure gauge stop valve 12, pressure gauge 13, volume adjustment plunger 14, back pressure stop valve 15, oil collector 16 and data processing and display system 17;

[0032] The pressure vessel 1 is a flat-top high-pressure cylindrical vessel, which contains fuel oil and acts as a measuring vessel. There is a fuel injector 2 on the top of the pressure vessel 1. One end of the fuel injector 2 is connected to the hollow interior of the pressure vessel 1, and the other end is connected to the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com