Fuel injection rule measuring device of diesel engine and measuring method thereof

A fuel injection law and measurement device technology, which is applied in the field of diesel engine fuel injection law measurement devices, can solve the problems of decreased measurement accuracy and expensive single injection measurement system, and achieve the effect of ensuring accuracy and eliminating measurement interference

Inactive Publication Date: 2010-09-08

BEIHANG UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Multiple injections may occur in the high-pressure common rail. If the interval between two injections is small, the result of the last injection measured by the plunger displacement method will be significantly affected by the vibration of the previous injection, so the measurement accuracy will drop significantly.

In addition, the single injection measurement system based on the plunger displacement method to measure the injection law is expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

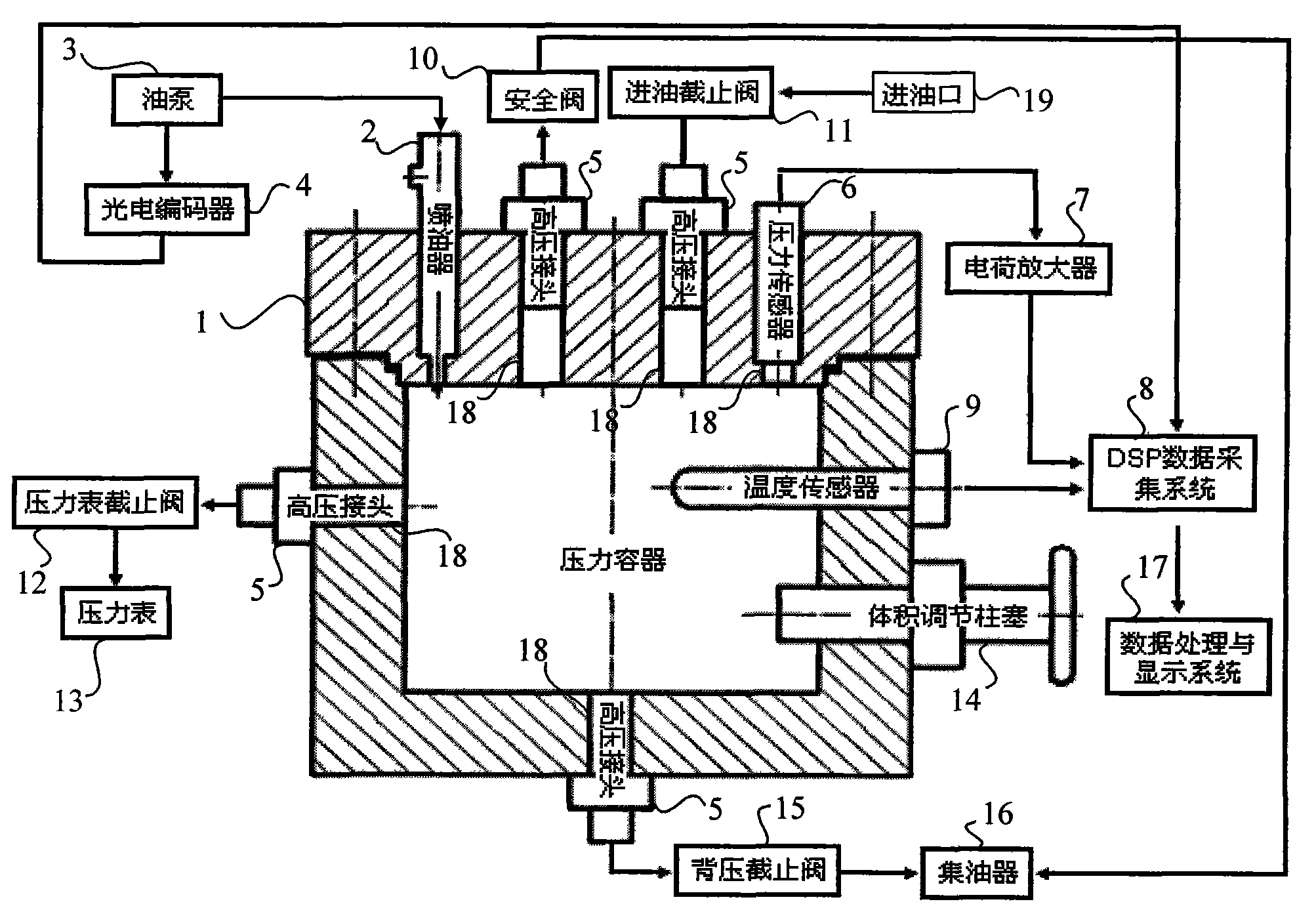

The invention discloses a fuel injection rule measuring device of a diesel engine and a measuring method thereof. The device comprises a pressure vessel, an oil atomizer, an oil pump, a photoelectric encoder, a high pressure connector, a pressure sensor, a charge amplifier, a DSP data acquisition system, a temperature sensor, a safety valve, a feeding disconnecting valve, a pressure meter disconnecting valve, a pressure meter, a volume regulating plunger, a back pressure disconnecting valve, an oil collector and a data processing and display system. The method includes that a measuring rule isobtained by utilizing Soave formula by acquiring the temperature and pressure of the pressure vessel and the angle signal of the oil pump. In the invention, the back pressure disconnecting valve is used for back pressure adjustment, the initial pressure in the pressure vessel is accurately controlled, environment back pressure injected by the oil atomizer is accurately simulated, and the volume adjusting plunger can adjust the volume of the pressure vessel. The invention eliminates that measuring interference between two adjacent injections in one injecting process which probably appears in plunger displacement method and ensures fuel injection rule measuring accuracy.

Description

technical field The invention relates to a measuring device and a measuring method for fuel injection regularity of a diesel engine, belonging to the field of engines. Background technique More and more stringent emission regulations put forward stricter requirements on the NOX and soot emission levels of diesel engines, and the ideal fuel injection law can reduce NOX and soot emissions of diesel engines at the same time, which is the key to realize the structure of fuel system, combustion chamber and air passage. One of the key factors for the matching of the three is one of the important factors affecting the combustion performance and emission performance of the engine. In the multi-dimensional calculation of diesel engine CFD, fuel injection rules are also needed to predict the spray characteristics of the engine, which has a great influence on the prediction of engine combustion performance. Therefore, it is very important to accurately obtain the fuel injection patter...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02M65/00

Inventor 李云清成传松何鹏赵立峰

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com