Hydraulic fatigue test system for pressure container

A fatigue test and pressure vessel technology, applied in presses, using repetitive force/pulse force to test the strength of materials, punching machines, etc., can solve the problems of easy wear, damage and complex control of solenoid valves and hydraulic components Achieving, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

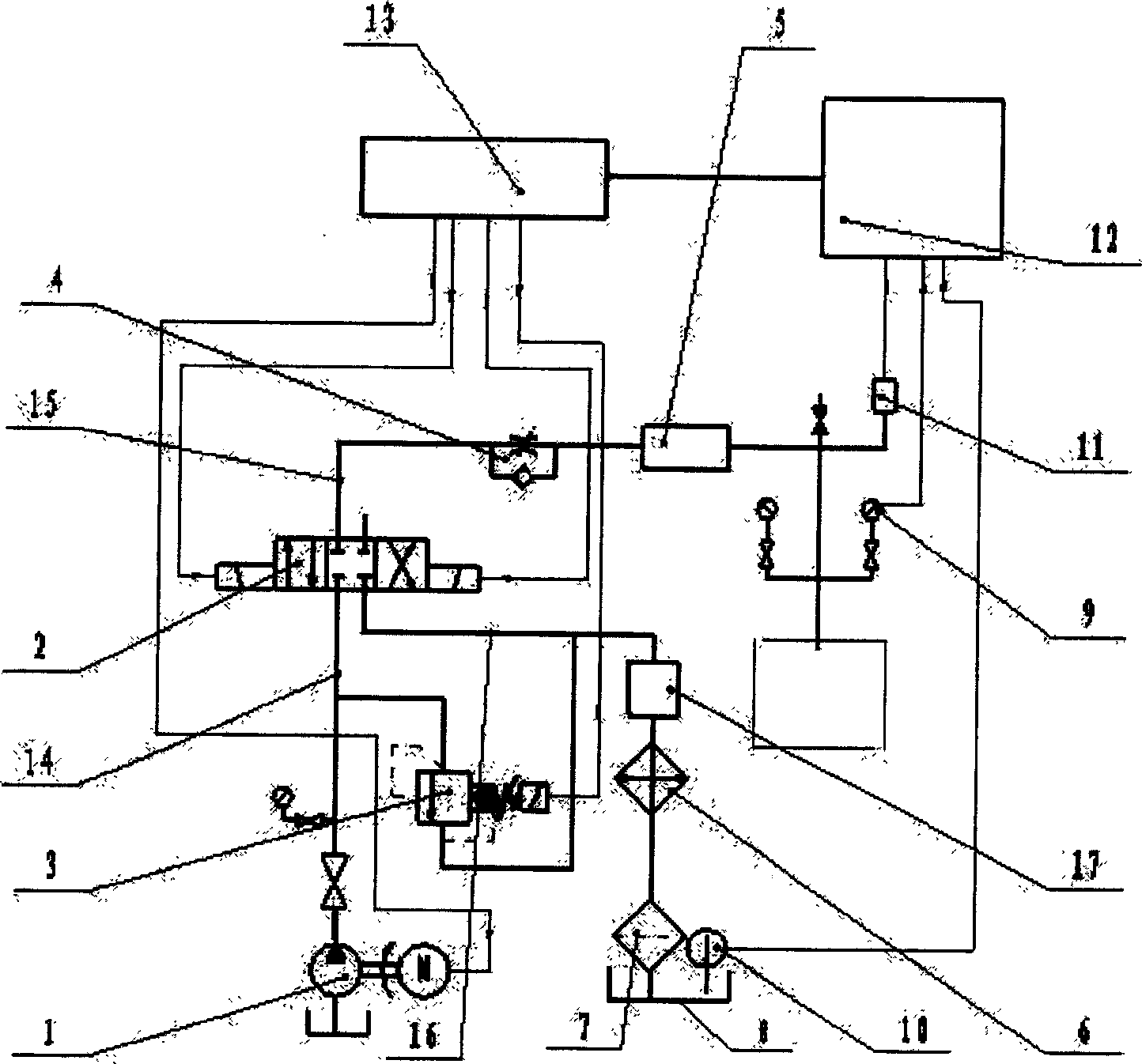

[0014] A fatigue test system for a pressure vessel, which comprises: an oil pump 1 driven by a motor connected by pipelines, a solenoid valve 2, an electromagnetic overflow valve 3, a one-way throttle valve 4, a high-pressure filter device 5, and a water-cooled oil cooling system. 6, the oil return filter device 7 and the oil tank 8 are composed of the oil circuit pressurization, pressure maintenance and pressure relief device, and the electric contact pressure gauge 9, temperature sensor 10, pressure sensor for pressure vessel and hydraulic oil temperature measurement and control 11. A measurement control system composed of a computer 12 and a controller 13.

[0015] The signals from the pressure sensor 11, the electric contact pressure gauge 12, and the temperature sensor 10 are all connected to the computer through wires. After inputting necessary data and relevant information to the computer 12 as required, the controller 13 starts the motor according to the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com