Diesel engine oil test bed system

A diesel engine and test bench technology, applied in the direction of internal combustion engine testing, etc., to achieve the effect of advanced control technology, good use effect, and advanced automatic adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

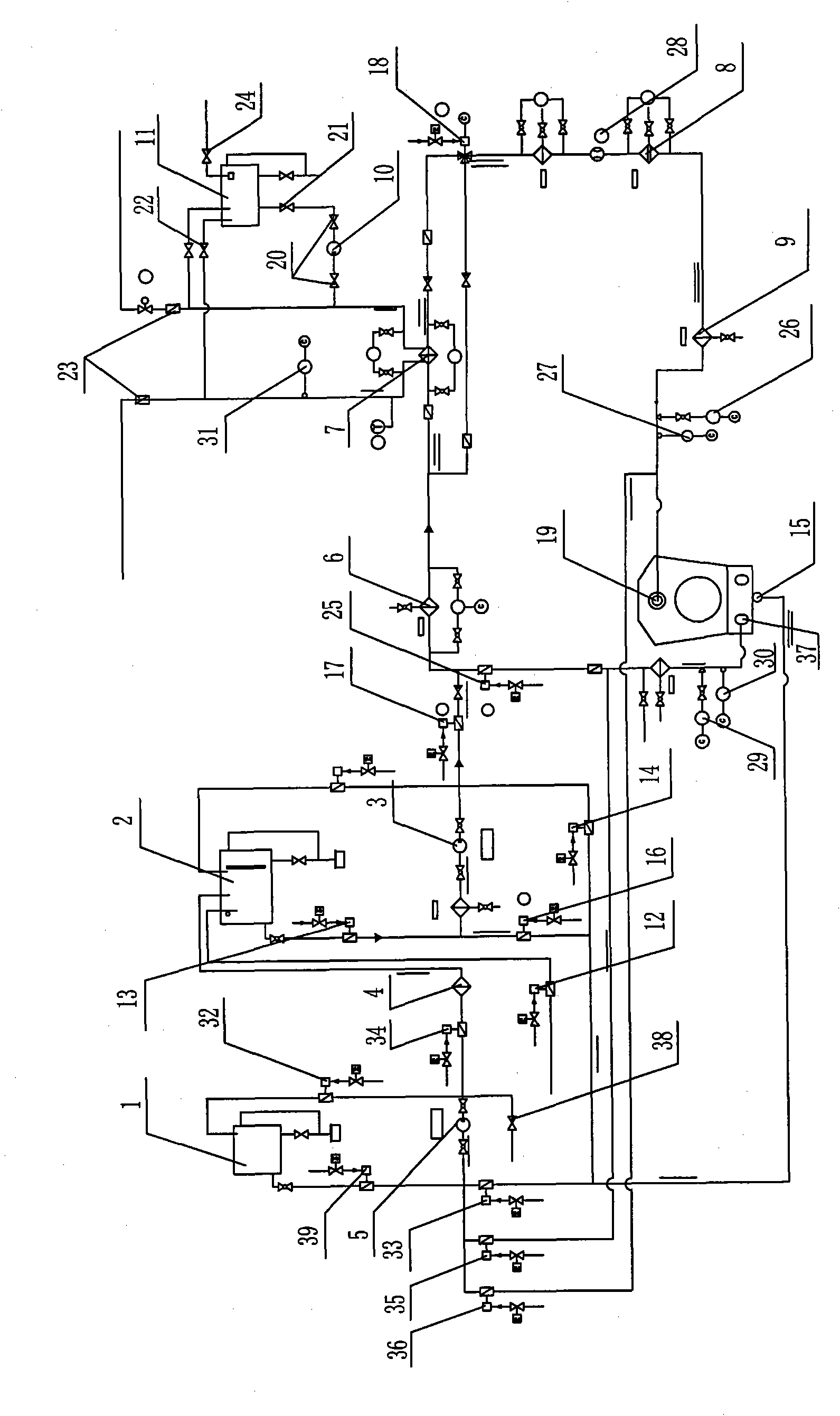

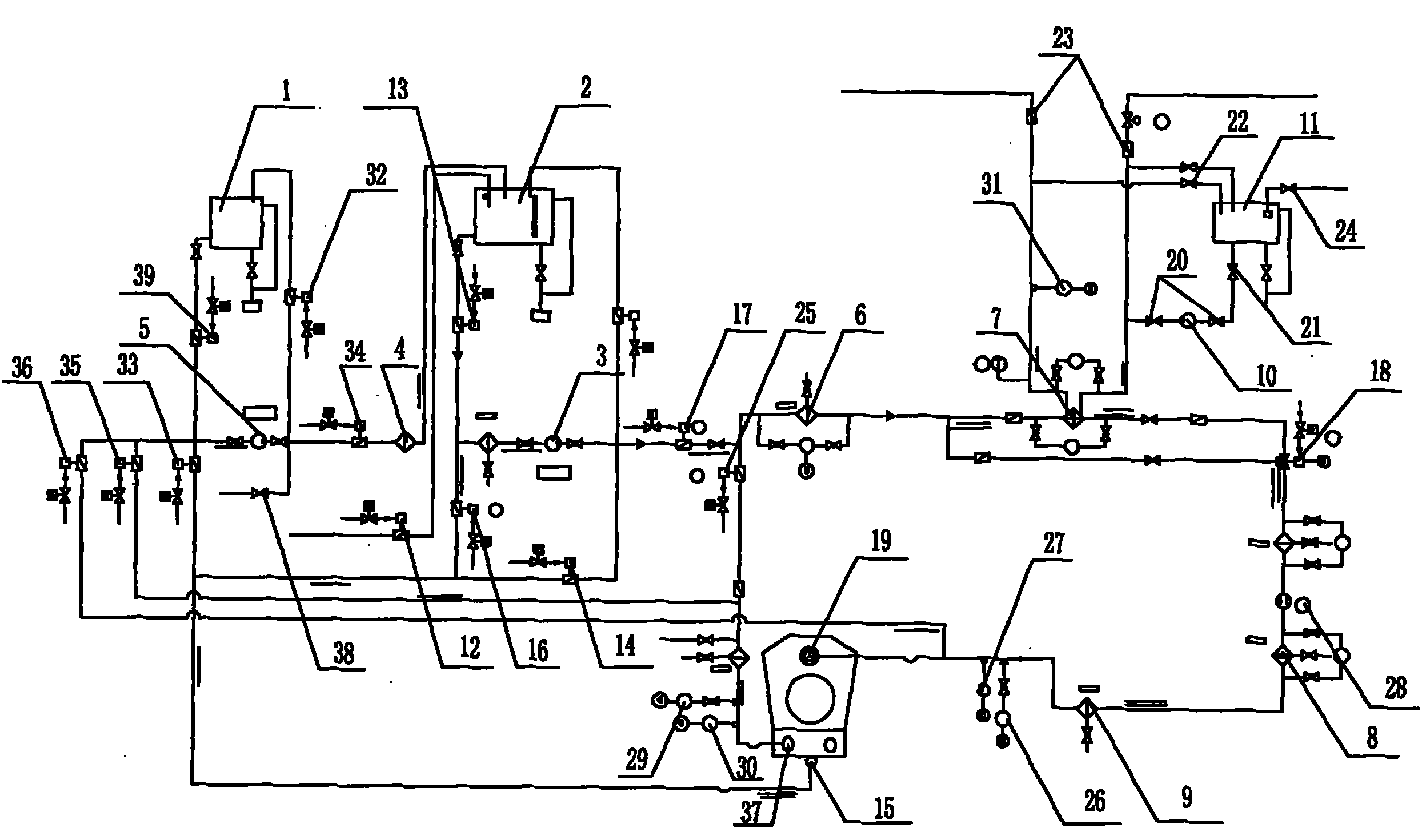

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] A diesel engine test bench system includes an oil return filter box 1, a clean oil tank 2, a clean oil pump 3, a coarse oil filter 4, a lubricating oil return pump 5, an oil filter 6, a heat exchanger 7, a fine oil filter 8, Engine oil import and export coarse filter 9, preheating water pump 10, diesel engine oil pan 15, engine oil preheating water tank 11, oil supply valve 12, oil filling valve 13, refueling valve 14, circulation control valve 16, system refueling valve 17, electric temperature adjustment Control 18, diesel engine oil inlet 19, external cooling water valve 23, steam valve 24, valve 25, engine oil inlet pressure sensor 26, engine oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com