Antibacterial plastic for household appliances and preparation method thereof

A technology for antibacterial plastics and home appliances, applied in the field of polymer engineering plastics, can solve the problems of high cost of use, color of copper ions, active chemical properties, etc., and achieve the effects of improving strength, good antibacterial effect, and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

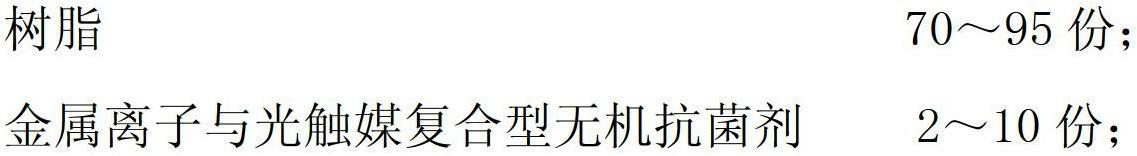

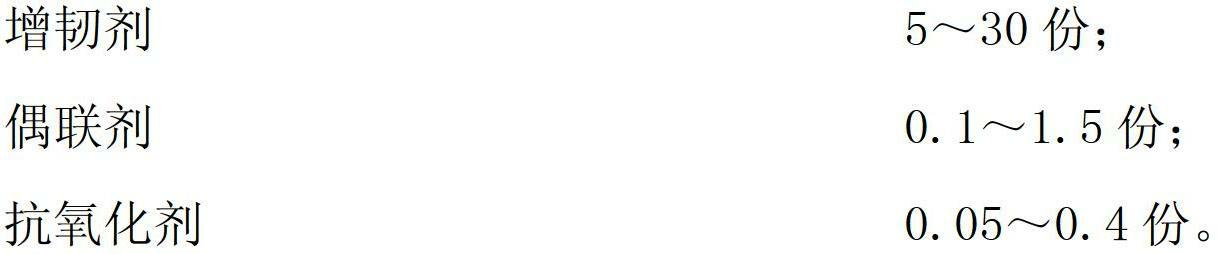

Method used

Image

Examples

preparation example Construction

[0049] In the preparation method of the above-mentioned antibacterial plastic for household appliances, after mixing various raw materials uniformly, the antibacterial plastic for household appliances can be prepared by blending at a temperature range of 170-240°C. If the temperature is too low, the material will not be plasticized well in the extruder, and if the temperature is too high, the polymer material will be oxidized and decomposed to destroy the molecular structure.

[0050] Wherein, in the above method, an extruder is used for blending, the heating temperature is 170-230°C, and the extruding temperature of the head is 200-235°C.

[0051] Further, when blending, the screw speed of the extruder host is 10-50 r / min, the feeding speed is 5-30 r / min; the blending time is 1-6 minutes.

[0052] Further, the blending time is preferably 2 minutes.

Embodiment 1

[0054] The preparation and performance of embodiment one antibacterial plastics of the present invention

[0055] Weigh various raw materials according to the raw material formula in Table 1, wherein the resin is selected as ABS resin (the content of acrylonitrile is 20%, the Vicat softening point is 103°C, and under the conditions of 200°C and 10Kg, its melt index is 23g / 10min ); the antibacterial agent is a silver-loaded nano-titanium dioxide antibacterial agent (the particle size of the composite powder is less than 30nm, and the weight ratio of silver to titanium dioxide is: silver: titanium dioxide = 3:100); toughening agent (methyl acrylate-butadiene - Styrene terpolymer, wherein the weight percent content of methyl acrylate is 25%, the content of butadiene is 15%, and the content of styrene is 60%); the coupling agent is silane coupling agent KH560; ABS, antibacterial agent Dry at 80°C for 4 hours before use; add various raw materials (including auxiliary antioxidants, ...

Embodiment 2

[0056] Preparation and performance of embodiment two antibacterial plastics

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com