Thermoplastic polyester composition and preparation method thereof

A technology for thermoplastic polyester and composition, applied in the field of thermoplastic polyester composition and its preparation, can solve the problems of low cost performance, narrow application range, no competitiveness, etc., and achieve the advantages of low product cost, strong competitiveness, and promotion of development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

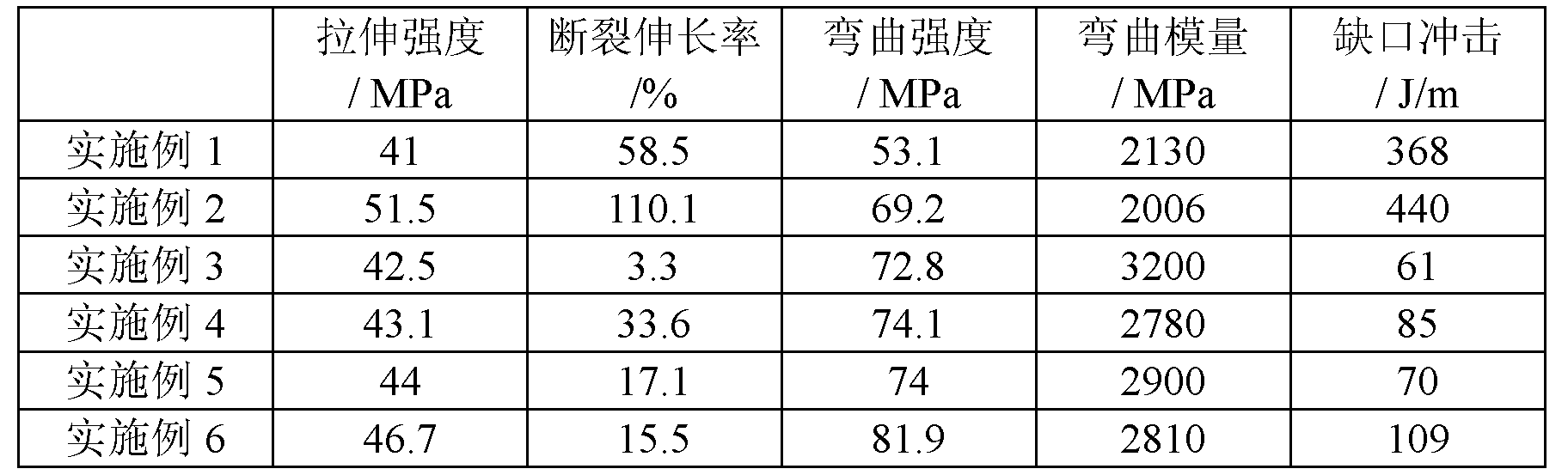

Examples

Embodiment 1

[0043] 40 parts of polyethylene terephthalate resin, 29 parts of recycled polyethylene terephthalate, 15 parts of recycled styrene-butadiene rubber, 10 parts of styrene-butadiene rubber grafted with maleic anhydride, 5 parts of calcium carbonate, Add 0.2 parts of vinyltrichlorosilane, 0.3 parts of lubricant stearamide, 0.2 parts of antioxidant 1010 and 0.3 parts of antioxidant 168 into a high-speed mixer and mix for 5 minutes. The compound is fed into the twin-screw extruder from the feeding port of the extruder, and the extrusion temperatures are 210°C, 265°C, 270°C, 270°C, and 275°C, respectively, and extruded to granulate.

Embodiment 2

[0045] Add 50 parts of polybutylene terephthalate resin, 45 parts of recycled polybutylene terephthalate, and 5 parts of recycled polycarbonate into a high-speed mixer, and mix for 5 minutes. The compound is fed into the twin-screw extruder from the feed port of the extruder, and the extrusion temperatures are 200°C, 240°C, 240°C, 240°C, and 245°C, respectively, and extruded to granulate.

Embodiment 3

[0047] 37 parts of polyethylene terephthalate resin, 15 parts of recycled polypropylene, 10 parts of polypropylene grafted maleic anhydride, 35 parts of carbon black, 1 part of Y-chloropropyltriethoxysilane, 1 part Lubricant Zinc Stearate, 1 part Antioxidant 300 were added to the high-speed mixer and mixed for 10 minutes. The compound is fed into the twin-screw extruder from the feeding port of the extruder, and the extrusion temperatures are 210°C, 265°C, 265°C, 265°C, and 270°C, respectively, and extruded to granulate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com