Preparation method of composite material for inorganic modified melamine chlorinated isocyanurate flame-retardant nylon 6

A technology of melamine cyanurate and inorganic modification is applied in the preparation of composite materials and the field of preparation of inorganic modified melamine cyanurate flame retardant nylon 6 composite materials, which can solve the problem of color deterioration of composite materials and other problems of composite materials. Performance degradation, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

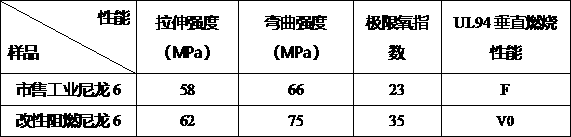

[0016] Preparation of silica-modified melamine cyanurate flame-retardant nylon 6 composite material: add 2 kg of caprolactam to a 5-liter polymerization kettle, heat up to 70 ° C, add 65 g of melamine, 65 g of cyanuric acid and 15 ml of orthosilicic acid Ethyl ester, adjust the pH value to 2.0, react for 2 hours, replace the air in the kettle with high-purity nitrogen, raise the temperature to 180°C, pressurize to 1.0MPa, polymerize for 3 hours, then depressurize to -1.0MPa, polymerize for 13 hours, The material is discharged to obtain a silica-modified melamine cyanurate flame-retardant nylon 6 composite material, which is extracted with water and dried to obtain a finished product. The flame retardant performance and mechanical performance test of the product obtained by implementing Lee 1 are carried out, and the commercially available industrial nylon 6 sample is tested simultaneously. See Table 1 for the data.

[0017] Table I

[0018]

Embodiment 2

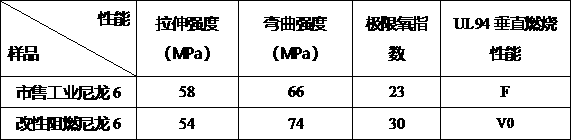

[0020] Preparation of silica-modified melamine cyanurate flame-retardant nylon 6 composite material: add 2 kg of caprolactam to a 5-liter stainless steel polymerization kettle, heat up to 100 ° C, add 50 g of melamine, 50 g of cyanuric acid and 15 ml of orthosilicone Ethyl acetate, adjust the pH value to 6.0, react for 2 hours, replace the air in the kettle with high-purity nitrogen, raise the temperature to 280°C for polymerization for 2 hours, then reduce the pressure to -1.0MPa, polymerize for 1 hour, and discharge the material to obtain two Silica-modified melamine cyanurate flame-retardant nylon 6 composite material, extracted with water and dried to obtain a finished product. The flame retardancy and mechanical properties of the product obtained in the implementation of Lee 2 were tested, and the commercially available industrial nylon 6 samples were tested at the same time. See Table 2 for the data.

[0021] Table II

[0022]

Embodiment 3

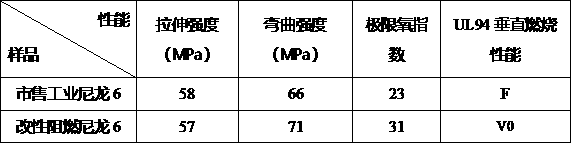

[0024] Preparation of graphene oxide modified melamine cyanurate flame retardant nylon 6 composite material: add 2 kg of caprolactam to a 5 liter stainless steel polymerization kettle, heat up to 95°C, add 80 g of melamine, 80 g of cyanuric acid and graphene oxide 120 ml of 0.8 grams of colloid, adjust the pH value to 10.0, react for 1.5 hours, replace the air in the kettle with high-purity nitrogen, heat up to 260 ° C for 4 hours, then reduce the pressure to -0.8MPa, polymerize for 1.5 hours, and discharge , the graphene oxide modified melamine cyanurate flame-retardant nylon 6 composite material was obtained, extracted with water, and dried to obtain a finished product. The flame retardant performance and mechanical performance test of the product obtained by implementing Lee 3 are carried out, and the commercially available industrial nylon 6 samples are tested at the same time. See Table 3 for the data.

[0025] Table three

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com