Glass fiber reinforced nylon material used for extrusion molding, preparation method and application

An extrusion molding, glass fiber technology, applied in the field of high melt strength glass fiber reinforced nylon material and its preparation field, can solve the problems of mechanical properties of extrusion molding products, etc., achieve excellent appearance, high melt strength, guarantee The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

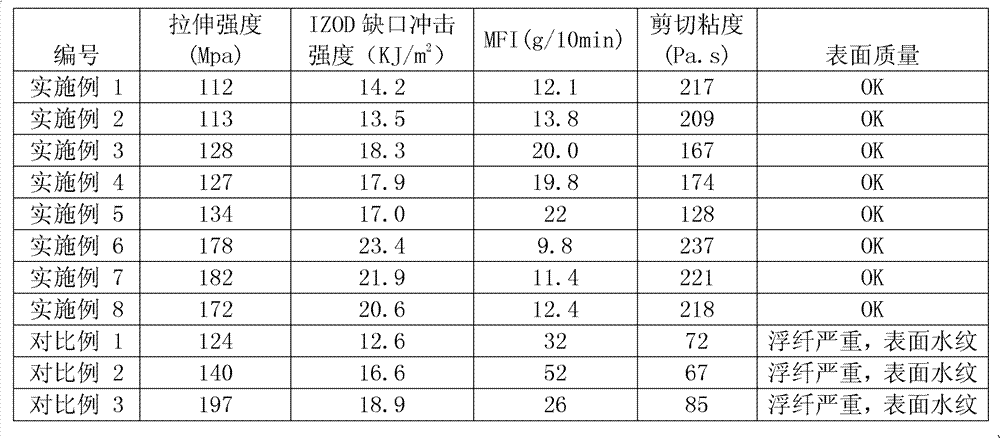

Examples

Embodiment 1

[0046] A method for preparing a glass fiber reinforced nylon material for extrusion molding, comprising the following steps:

[0047] 56 parts by mass of PA66 (viscosity 2.6), 8 parts by mass of extrusion molding surface improver HDPE, 3 parts by mass of toughening agent MAH-g-POE, 2.5 parts by mass of chain extender SMA (maleic anhydride content 25%), 0.1 Parts by mass of antioxidant 1098, 0.2 part by mass of lubricant oxidized polyethylene wax, 0.2 part by mass of nucleating agent talcum powder, mixed uniformly with a pre-mixer at room temperature, fed by a metering scale through the main feed port of a twin-screw extruder ; 15 parts by mass of aminosilane coupling agent-modified glass fiber (diameter 12 μm) is fed through the side feeding port of the fifth zone by the metering scale. Using a twin-screw extruder to extrude and granulate, the conditions for extrusion and granulation are as follows: the temperature of the first zone is 220°C, the temperature of the second zone...

Embodiment 2

[0049] A method for preparing a glass fiber reinforced nylon material for extrusion molding, comprising the following steps:

[0050] 59 parts by mass of PA66 (viscosity 2.9), 8 parts by mass of extrusion surface improver HDPE, 2 parts by mass of toughening agent MAH-g-POE, 0.5 parts by mass of chain extender SMA (maleic anhydride content 25%), 0.1 Parts by mass of antioxidant 1098, 0.2 parts by mass of lubricant montanic acid wax, 0.2 parts by mass of nucleating agent talcum powder, mixed uniformly with a pre-mixer at room temperature, fed by a metering scale through the main feed port of a twin-screw extruder; 15 parts by mass of aminosilane coupling agent-modified glass fibers (diameter 12 μm) are fed through the side feeding port of the fifth zone from the metering scale. Using a twin-screw extruder to extrude and granulate, the conditions for extrusion and granulation are as follows: the temperature of the first zone is 220°C, the temperature of the second zone is 270°C, ...

Embodiment 3

[0052] A method for preparing a glass fiber reinforced nylon material for extrusion molding, comprising the following steps:

[0053] 59 parts by mass of PA6 (viscosity 2.8), 7 parts by mass of extrusion molding surface improver LDPE, 3 parts by mass of toughening agent MAH-g-EPDM, 0.5 parts by mass of chain extender M1251 (produced by Bruggemann), 0.1 parts by mass 168 parts of antioxidant, 0.2 parts by mass of lubricant calcium stearate, 0.2 parts by mass of nucleating agent sodium carboxylate, mixed uniformly with a premixer at room temperature and fed through the main feed port of the twin-screw extruder; 25 parts by mass A glass fiber (15 μm in diameter) modified by an aminosilane coupling agent is fed through the side feeding port of the fifth zone. Using a twin-screw extruder to extrude and granulate, the conditions for extrusion and granulation are as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 220°C, the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com