Foaming modified asphalt composition and preparation method thereof

A technology of modified asphalt and composition, which is applied to building structures, building components, building insulation materials, etc., can solve the problems of high temperature required for asphalt heating and no addition, and save production steps, prevent aging, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

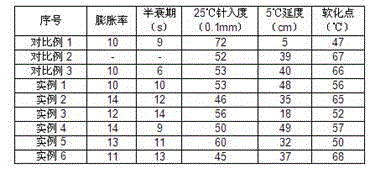

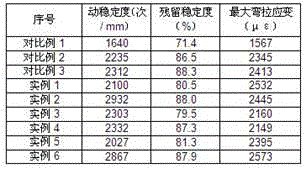

Examples

Embodiment 1

[0033] The foamed modified asphalt composition of the present embodiment comprises 10kg base asphalt and 1.1kg aqueous emulsion, wherein the aqueous emulsion comprises:

[0034] 35wt% styrene-butadiene rubber

[0035] 2 wt% Span-80 emulsifier

[0036] 1 wt% quaternary ammonium surfactant

[0037] 1 wt% silane coupling agent

[0038] 61 wt% water.

[0039] The preparation method of foamed modified asphalt of the present invention comprises the following steps:

[0040] 1) Heat 10kg of base asphalt to 150°C and keep it warm for use;

[0041] 2) Cut the hot base asphalt and 1.1kg of water-based emulsion in step 1) through a colloid mill with dual functions of shearing and grinding, and grind them evenly, and spray out the obtained product under a pressure of not less than 0.4MPa.

Embodiment 2

[0043] The foamed modified asphalt composition of the present embodiment comprises 10kg base asphalt and 1.2kg aqueous emulsion, wherein the aqueous emulsion comprises:

[0044] 38wt% styrene-butadiene-styrene block copolymer (SBS)

[0045] 2 wt% Span-60 emulsifier

[0046] 1 wt% amide surfactant

[0047] 1 wt% aluminate coupling agent

[0048] 58 wt% water.

[0049] The preparation method of foamed modified asphalt of the present invention comprises the following steps:

[0050] 1) Heat 10kg of base asphalt to 160°C and keep it warm for use;

[0051] 2) Cut the hot base asphalt and 1.2kg of water-based emulsion in step 1) through a colloid mill with dual functions of shearing and grinding, grind them evenly, and spray out the obtained product under a pressure of not less than 0.4MPa.

Embodiment 3

[0053] The foamed modified asphalt composition of the present embodiment comprises 10kg base asphalt and 1.0kg aqueous emulsion, wherein the aqueous emulsion comprises:

[0054] 44wt% neoprene

[0055] 4 wt% Span-20 emulsifier

[0056] 1.5 wt% sodium rosinate

[0057] 1.5 wt% titanate coupling agent

[0058] 49 wt% water.

[0059] The preparation method of foamed modified asphalt of the present invention comprises the following steps:

[0060] 1) Heat 10kg of base asphalt to 170°C and keep it warm for use;

[0061] 2) Cut the hot base asphalt and 1.0kg of water-based emulsion in step 1) through a colloid mill with dual functions of shearing and grinding, grind them evenly, and spray out the obtained product under a pressure of not less than 0.4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com