Cold-stirring cold-paving type epoxy modified asphalt material and preparation method thereof

A technology of epoxy modification and asphalt material, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of high price, secondary cracking, poor toughness of asphalt binder, etc., to suppress insufficient toughness and improve fatigue toughness , the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

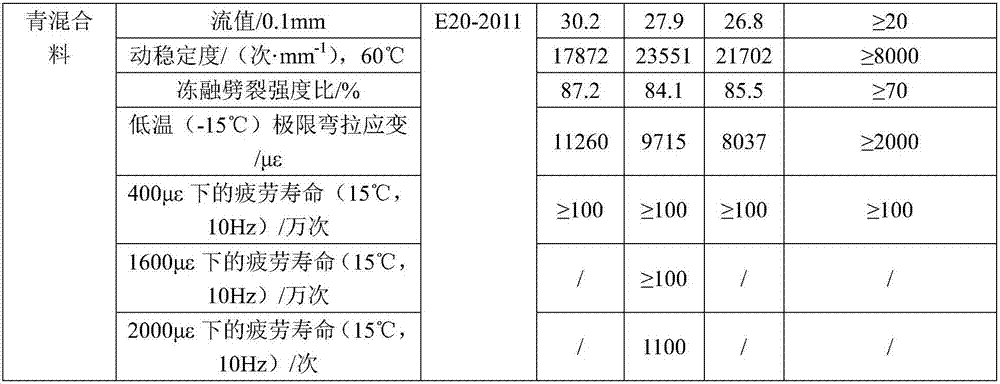

Examples

Embodiment 1

[0045] The preparation method of the first cold-mixed and cold-paved epoxy-modified asphalt material of the present invention has the following steps:

[0046] Put 10 parts of cardanol glycidyl ether into the reaction kettle, and after it is heated to 100°C, add 10 parts of Korean Ssangyong No. 70 asphalt that has been heated to 120°C in advance, the stirring speed is 60r / min, and the stirring and mixing time is 30min to obtain a liquid Asphalt; put 10 parts of E-54, 80 parts of self-made epoxy-terminated polysulfide rubber, 10 parts of phenyl glycidyl ether and 1 part of β-(3,4-epoxycyclohexyl) ethyl trimethoxysilane in sequence In the liquid asphalt, after the material in the kettle rose to 60°C, continue to stir and mix for 120min at a stirring rate of 60r / min to obtain cold-mix and cold-pavement epoxy-modified asphalt main agent A; 67 parts of self-made amino-terminated polyurethane prepolymer , 33 parts of isophorone diamine and 1 part of triethanolamine are put into the ...

Embodiment 2

[0048] The preparation method of the second cold-mixed cold-paved epoxy-modified asphalt material of the present invention has the following steps:

[0049] Put 20 parts of epoxy fatty acid methyl ester into the reaction kettle, and after it is heated to 80°C, add 20 parts of Korean Ssangyong No. 90 asphalt that has been heated to 120°C in advance, the stirring speed is 60r / min, and the stirring and mixing time is 30min to obtain a liquid Asphalt; Put 20 parts of E-51, 70 parts of self-made epoxy-terminated polyurethane prepolymer, 10 parts of C12-14 alkyl glycidyl ether and 1 part of γ-glycidyloxypropyltrimethoxysilane into liquid asphalt in sequence , after the material in the kettle rises to 60°C, continue to stir and mix for 120min at a stirring rate of 60r / min to obtain cold-mix and cold-pavement epoxy-modified asphalt main agent A; mix 50 parts of D-230, 50 parts of N-aminoethyl Piperazine and 1 part of DMP-30 were put into the reaction kettle in turn, stirred and mixed ...

Embodiment 3

[0051] The preparation method of the third cold-mixing and cold-paving epoxy-modified asphalt material of the present invention has the following steps:

[0052] Put 10 parts of castor oil glycidyl ether into the reaction kettle, after it is heated up to 90°C, add 10 parts of Korean Ssangyong No. 90 asphalt preheated to 120°C, the stirring speed is 60r / min, and the stirring and mixing time is 30min to obtain a liquid Asphalt; put 30 parts of E-44, 60 parts of self-made epoxy-terminated nitrile rubber, 10 parts of polyethylene glycol diglycidyl ether and 1 part of γ-(methacryloyloxy)propyl trimethoxysilane in sequence In the liquid asphalt, after the material in the kettle rose to 80°C, continue to stir and mix for 120min at a stirring rate of 60r / min to obtain cold-mix and cold-pavement epoxy modified asphalt main agent A; mix 33 parts of D-400, 67 parts of 1 , 3-bis(aminomethyl)cyclohexane and 5 parts of nonylphenol were put into the reaction kettle in turn, stirred and mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com