Tread rubber material of low-rolling-resistance all-steel radial tire and preparation method thereof

A technology for all-steel radial tires and tread rubber, which is applied in the field of low-rolling-resistance all-steel radial tire tread rubber and its preparation, can solve the problems of starting and braking hysteresis on wet and slippery roads, poor performance of low rolling resistance, and related performance problems. To reduce the coefficient of rolling resistance, reduce fuel consumption, and achieve mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

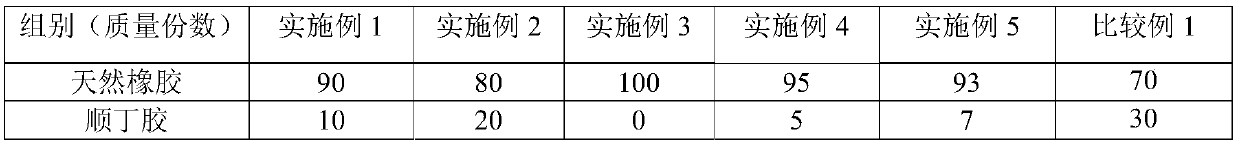

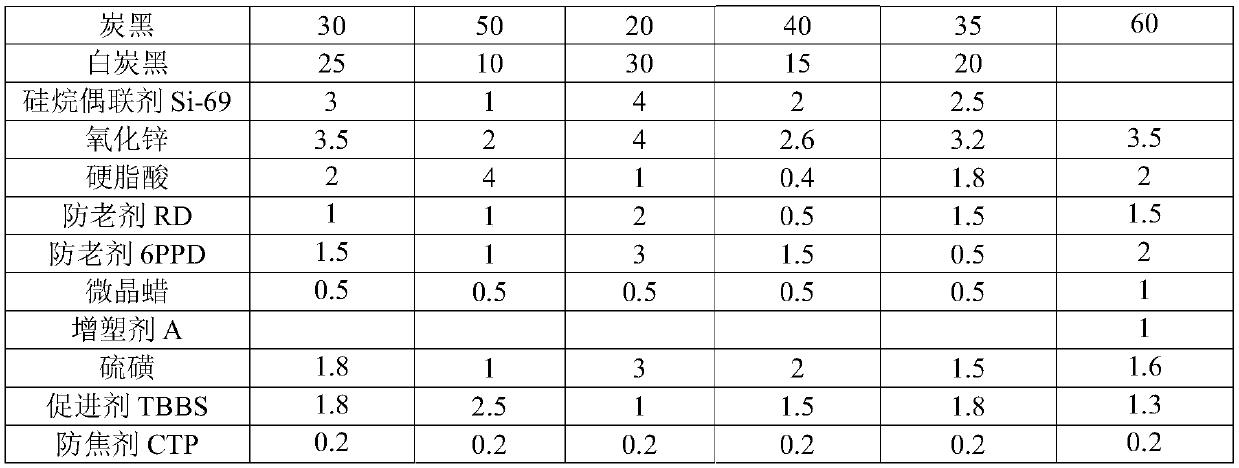

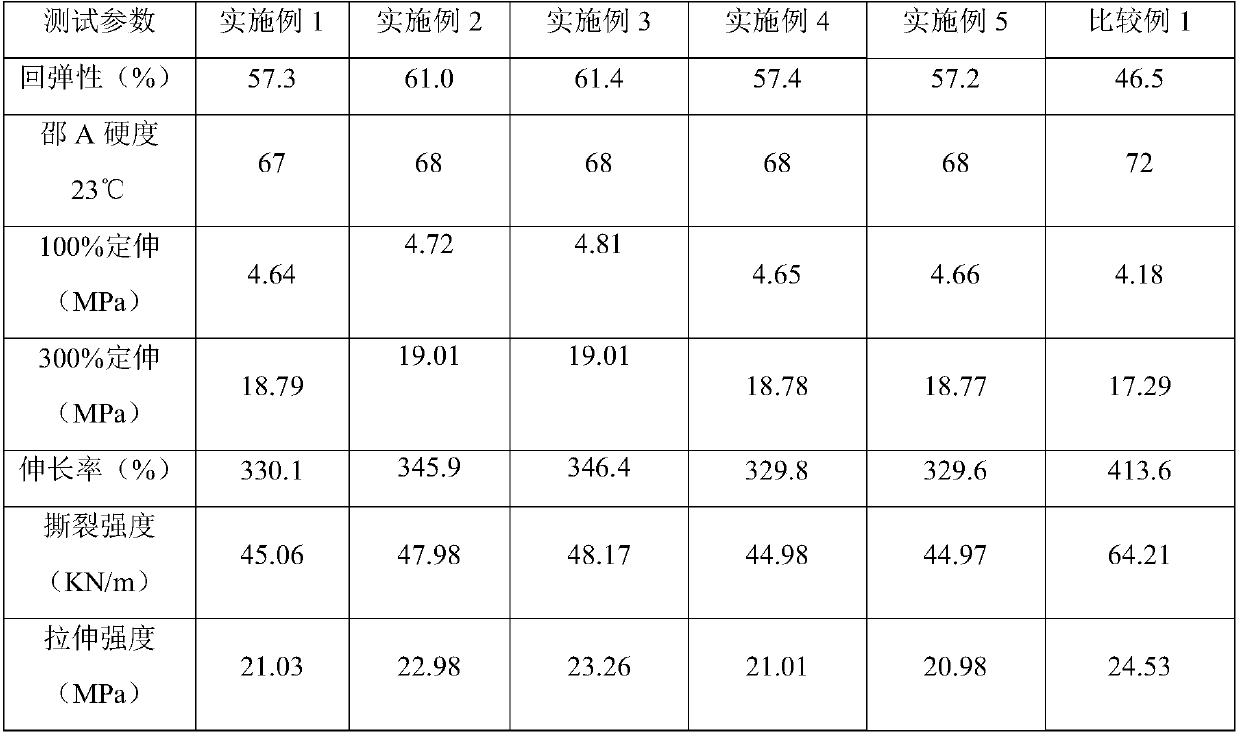

[0037] Embodiment 1-5, comparative example 1

[0038] The preparation method of the tread compound of low rolling resistance all-steel radial tire is carried out according to the following steps:

[0039] 1. Plastic mixing: set the speed of the internal mixer to 30rpm, add natural rubber and butadiene rubber into the internal mixer, press the bolt for 40s, lift the bolt for 30s, then press the bolt to 160°C and then discharge; after parking for 4 hours For masterbatch mixing;

[0040] 2. Masterbatch mixing: set the speed of the internal mixer to 55rpm, add plastic, zinc oxide, white carbon black, and silane coupling agent into the internal mixer, press the bolt for 30s, lift the bolt for 5s, and then press the bolt to 135 Lift the bolt after ℃ for 20s, then press the bolt to 155℃ and then discharge; after parking for 8 hours, it is used for one-time mixing;

[0041] 3. One-shot mixing: set the speed of the internal mixer to 55rpm, add masterbatch, stearic acid, carbon black, a...

Embodiment 6

[0047] Concrete formula is consistent with above-mentioned embodiment 5, just concrete preparation method is carried out according to the following steps:

[0048] 1. Plastic mixing: set the speed of the internal mixer to 55rpm, add natural rubber and butadiene rubber into the internal mixer, press the bolt for 70s, lift the bolt for 30s, then press the bolt to 170°C and then discharge; after parking for 8 hours For masterbatch mixing;

[0049] 2. Masterbatch mixing: set the speed of the internal mixer to 30rpm, add plastic, zinc oxide, white carbon black, and silane coupling agent into the internal mixer, press the bolt for 30s, lift the bolt for 5s, and then press the bolt to 135 Lift the bolt after ℃ for 20s, then press the bolt to 155℃ and then discharge; park for 24 hours and use it for one-time mixing;

[0050] 3. One-time mixing: set the speed of the internal mixer to 30rpm, add masterbatch, stearic acid, carbon black, and anti-aging agent into the internal mixer, pres...

Embodiment 7

[0052] Concrete formula is consistent with above-mentioned embodiment 5, just concrete preparation method is carried out according to the following steps:

[0053] 1. Plastic mixing: set the speed of the internal mixer to 45rpm, add natural rubber and butadiene rubber into the internal mixer, press the bolt for 50s, lift the bolt for 20s, then press the bolt to 165°C and then discharge; after parking for 6 hours For masterbatch mixing;

[0054] 2. Masterbatch mixing: set the speed of the internal mixer to 40rpm, add plastic, zinc oxide, white carbon black, and silane coupling agent into the internal mixer, press the bolt for 30s, lift the bolt for 5s, and then press the bolt to 135 After ℃, lift the plug and keep it for 20s, then press the plug to 155 °C and then discharge; after parking for 10 hours, it is used for one-time mixing;

[0055] 3. One-shot mixing: set the speed of the internal mixer to 40rpm, add masterbatch, stearic acid, carbon black, and anti-aging agent into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com