Porous tobacco material for heating non-combustion type cigarettes and preparation method of porous tobacco material

A technology for heating non-combustible tobacco, which is applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effects of easy release of smoke, simple preparation process, and improved sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

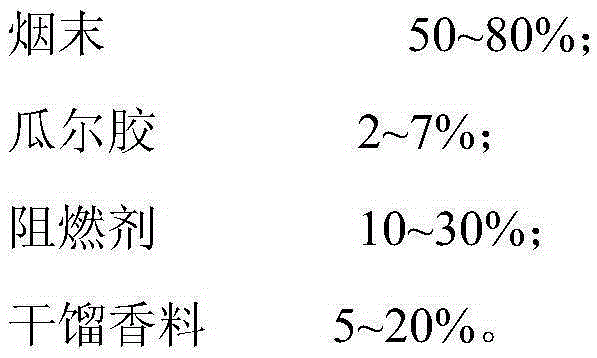

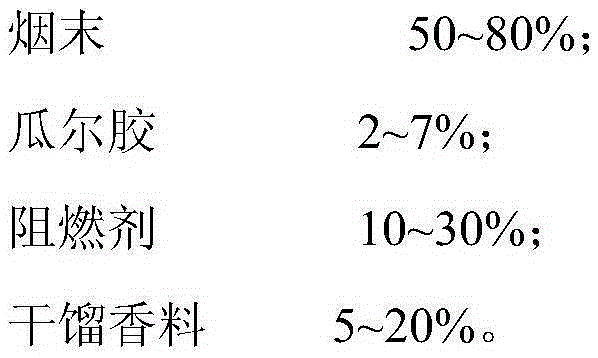

Method used

Image

Examples

Embodiment 1

[0022] Add 60g of flue-cured tobacco powder (50 mesh), 5g of guar gum, 10g of magnesium hydroxide and 15g of aluminum hydroxide into the mixer, and atomize 10g of dry distillation flavor (60% glycerol content) at a stirring speed of 1000 rpm And spray it on the material that is constantly thrown up. After the spraying is completed, continue to stir for 5 minutes to obtain the primary mixture of tobacco materials; send the above-mentioned primary mixture of tobacco materials into a single-screw extruder to continue mixing, and inject CO at the same time. 2 Carry out foam extrusion molding, the obtained extrudate is cut into 0.15mm thick, 2mm wide shredded tobacco with cutter after drying, obtains the porous tobacco material that is used for heating non-combustion type cigarette, and its average pore diameter is 100um, porosity is 30 %.

[0023] The tobacco material of this embodiment is used in the heating and non-combustion state, the smoke release rate is fast, the release am...

Embodiment 2

[0026] Add 40g Yunnan flue-cured tobacco powder (100 mesh), 20g Sichuan Burley tobacco powder (100 mesh), 10g Xinjiang spice powder (100 mesh), 2g guar gum, 10g magnesium hydroxide and 10g aluminum hydroxide to the mixer , at a stirring speed of 1500 rpm, atomize and spray 15 g of retort fragrance (50% glycerol content) on the material being continuously thrown up, and continue stirring for 5 minutes after the spraying is completed to obtain the primary mixture of tobacco materials; The primary mixture of the above-mentioned tobacco materials is fed into the single-screw extruder to continue mixing while injecting CO 2 Carry out foam extrusion molding, the obtained extrudate is cut into 0.2mm thick, 2mm wide shredded tobacco with cutter after drying, obtains the porous tobacco material that is used for heating non-combustion type cigarette, and its average pore diameter is 130um, and porosity is 40 %.

[0027] The tobacco material of this embodiment is used in a heating non-c...

Embodiment 3

[0030] 65g of Yunnan flue-cured tobacco powder (70 mesh), 7g of guar gum, 20g of magnesium hydroxide and 10g of aluminum hydroxide were added to the mixer, and at a stirring speed of 800 rpm, 20g of dry distillation flavor (70% glycerol content) was mist and spray it on the material that is continuously thrown up. After the spraying is completed, continue to stir for 5 minutes to obtain the primary mixture of tobacco materials; send the above primary mixture into the single-screw extruder to continue mixing, and inject CO at the same time. 2 Carry out foam extrusion molding, the obtained extrudate is cut into 0.3mm thick, 2mm wide shredded tobacco with cutter after drying, obtains the porous tobacco material that is used for heating non-combustion type cigarette, and its average pore diameter is 80um, and porosity is 35 %.

[0031] The tobacco material of this embodiment is used in the heating and non-combustion state, the smoke release rate is fast, the release amount is suff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com