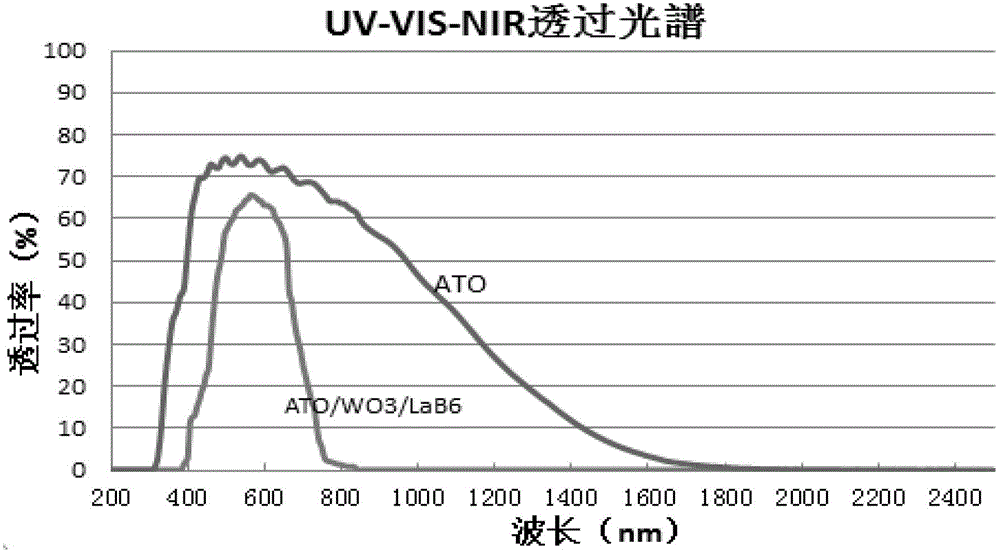

Full-shielded infrared and ultraviolet polyurethane nanometer transparent heat insulating coating

A heat-insulating coating and full-shielding technology, applied in the field of functional nano-materials, can solve problems such as limited energy-saving effects, and achieve the effects of improved transparency, improved weather resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the formula amount of Example 1 in Table 1, first add the polyurethane resin A component in the paint bucket, then add the nano-ATO dispersion and nano-LaB dropwise while stirring. 6 Dispersion, Nano WO 3 Dispersion, stirring and dispersing for 20min to 30min, then adding leveling agent, defoamer, adhesion promoter, solvent and curing agent B according to the formula ratio, stirring and mixing evenly, and filtering to obtain a fully shielding infrared and ultraviolet polyurethane nano Transparent thermal insulation coating.

Embodiment 2

[0030] Refer to Example 1 for the preparation process of Example 2 and Example 3.

[0031] According to relevant national standards, the basic performance of the nano polyurethane transparent heat-insulating coating of the present invention is tested, and the test results are shown in Table 2.

[0032] Table 2 Basic performance test results of nano-polyurethane transparent heat-insulating coating

[0033] Test items Test Results standard test Paint film appearance, color blue, transparent, smooth GB1927-79 hardness (pencil) ≥5H GB / T6739-1996 Adhesion, grade (circle method) 0 GB / T1720-79 Impact strength, cm 50 GB / T1732-93 Flexibility, mm 1 GB / T1731-93 Water resistance, immersion in water for 48h No significant changes GB / T1733-93 Heat resistance, bake at 100°C for 3h Paint film without bubbling, wrinkling, cracking and discoloration GB / T1735-79

[0034] The present invention adopts nanometer A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com