Water-soluble polyurethane curing agent and preparation method thereof

A water-based polyurethane and curing agent technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost, flammability, explosion, and pollution, and achieve sufficient cross-linking, complete reaction, and simple reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

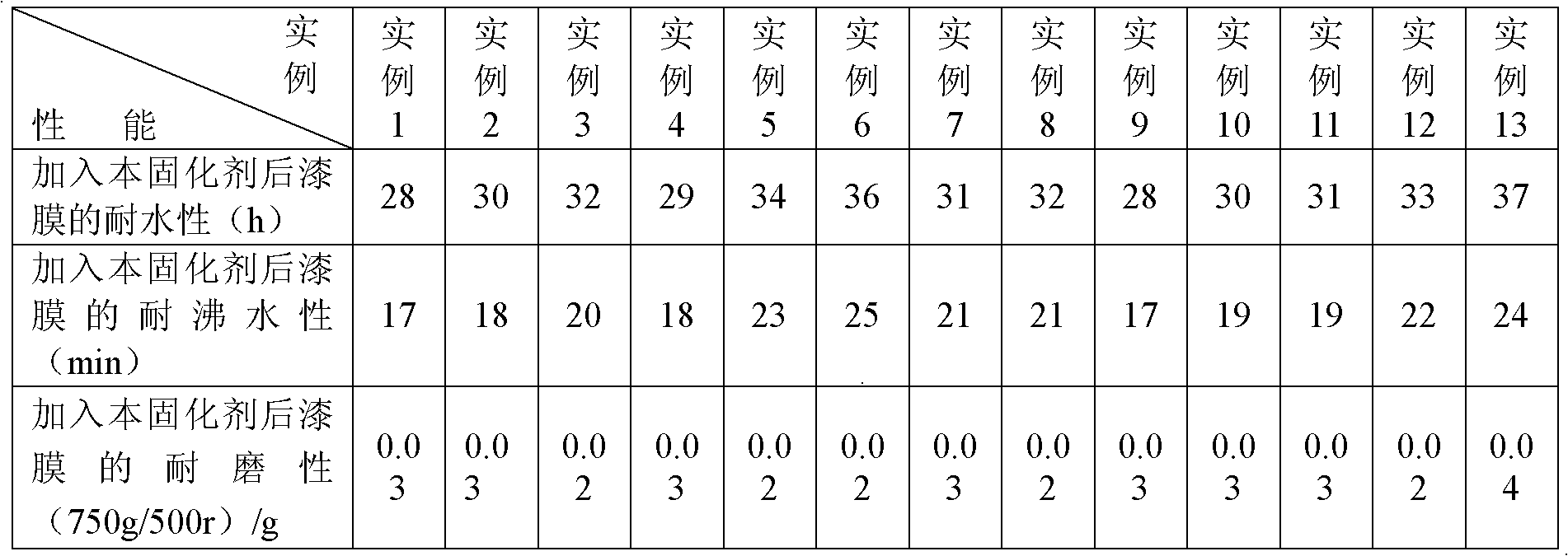

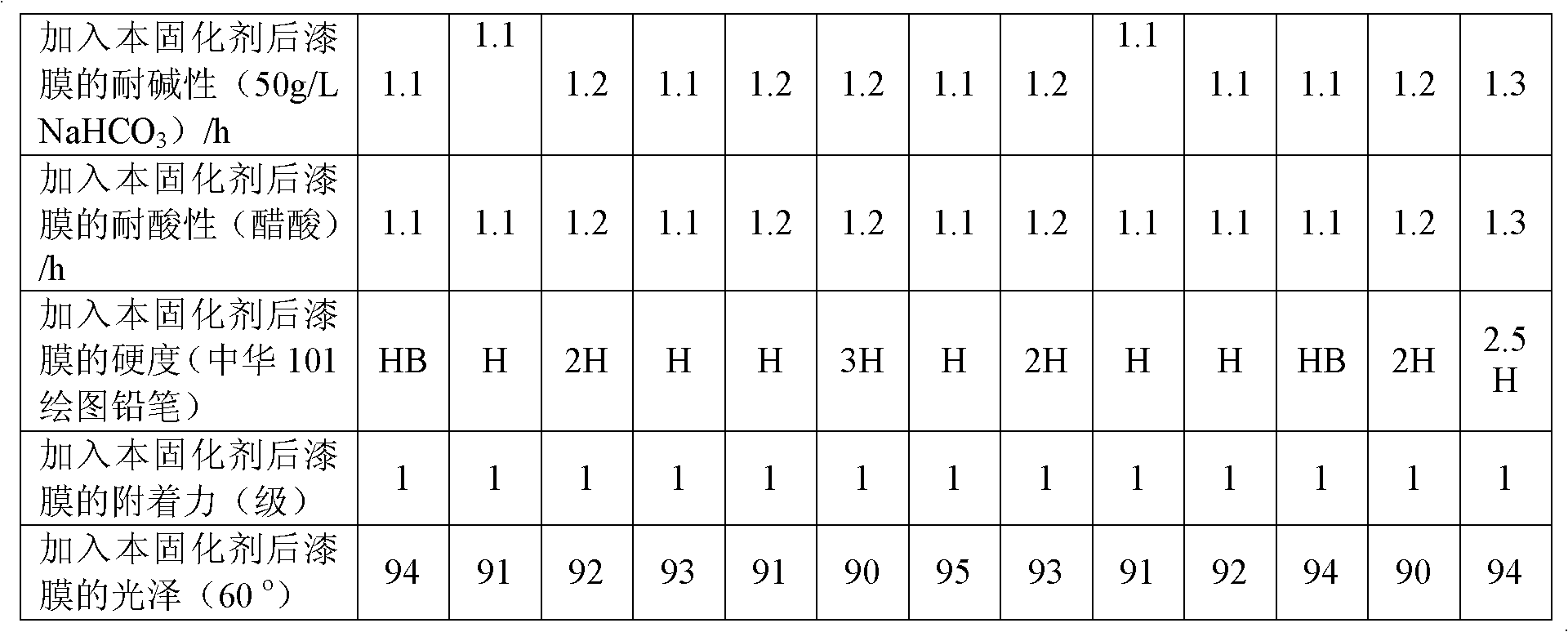

Examples

Embodiment 1

[0044] In a tank equipped with a stirrer, thermometer and 2 In the protected four-neck flask, add 180 grams of toluene diisocyanate, 408.9 grams of ethyl acetate and 400 grams of polycarbonate diol, heat up to 40 ° C, and then put 10 grams of trimethylolpropane into the reaction in three batches , and then kept at 70°C for 3 hours, and the weight percentage of NCO was detected. When the solid content was 55%, the temperature was lowered to 43°C, and 0.1 gram of polyethylene glycol was put into the reaction in two batches, and then kept at 58°C for 3 hours ; Add 0.2 g of tri-n-butylphosphine, keep warm at 50°C for 2.5 hours, add 0.8 g of phosphoric acid, stir evenly, cool to 20°C, and discharge.

Embodiment 2

[0046] In a tank equipped with a stirrer, thermometer and 2 In the protected four-neck flask, add 250 grams of toluene diisocyanate, 200.1 grams of ethyl acetate and 305.1 grams of polycarbonate diol, heat up to 50 ° C, and then put 50 grams of trihydroxymethylpropane into three batches of reaction, Then keep it at 80°C for 5 hours, detect the weight percentage of NCO, when the solid content is 65%, cool down to 48°C, put 200 grams of polyethylene glycol into the reaction in two batches, and then keep it at 63°C for 3 hours; Add 1 gram of tri-n-butylphosphine, keep warm at 60°C for 4 hours, add 4 grams of phosphoric acid, stir evenly, cool to 30°C, and discharge.

Embodiment 3

[0048] In a tank equipped with a stirrer, thermometer and 2In the protected four-neck flask, add 190 grams of toluene diisocyanate, 250 grams of acetone and 128 grams of polycarbonate diol, heat up to 45 ° C, and then put 30 grams of trimethylolpropane into three batches of reaction, and then in Incubate at 75°C for 4 hours, detect the weight percentage of NCO, when the solid content is 60%, cool down to 45°C, put 400 grams of polyethylene glycol into the reaction in two batches, and then keep at 60°C for 3 hours; add 1 gram of tri-n-butylphosphine, heat-preserve at 55°C for 3 hours, add 1 gram of phosphoric acid, stir evenly, cool to 25°C, and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com