Granite texture ceramic tile and preparation method thereof

A granite and texture technology, applied in the field of ceramic tiles, can solve the problems of high price, limited range of use of natural granite stone, color difference in the paving process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

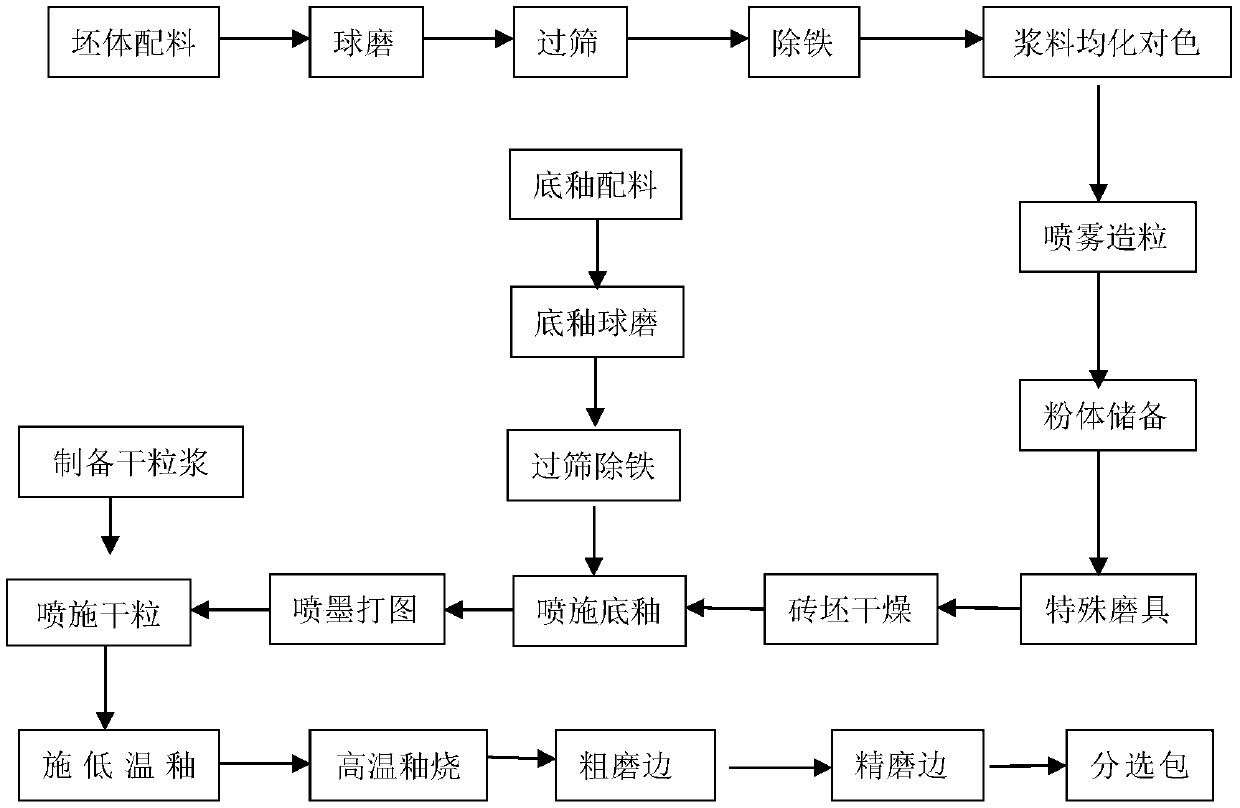

Method used

Image

Examples

Embodiment Construction

[0043] 1. Preparation of green body

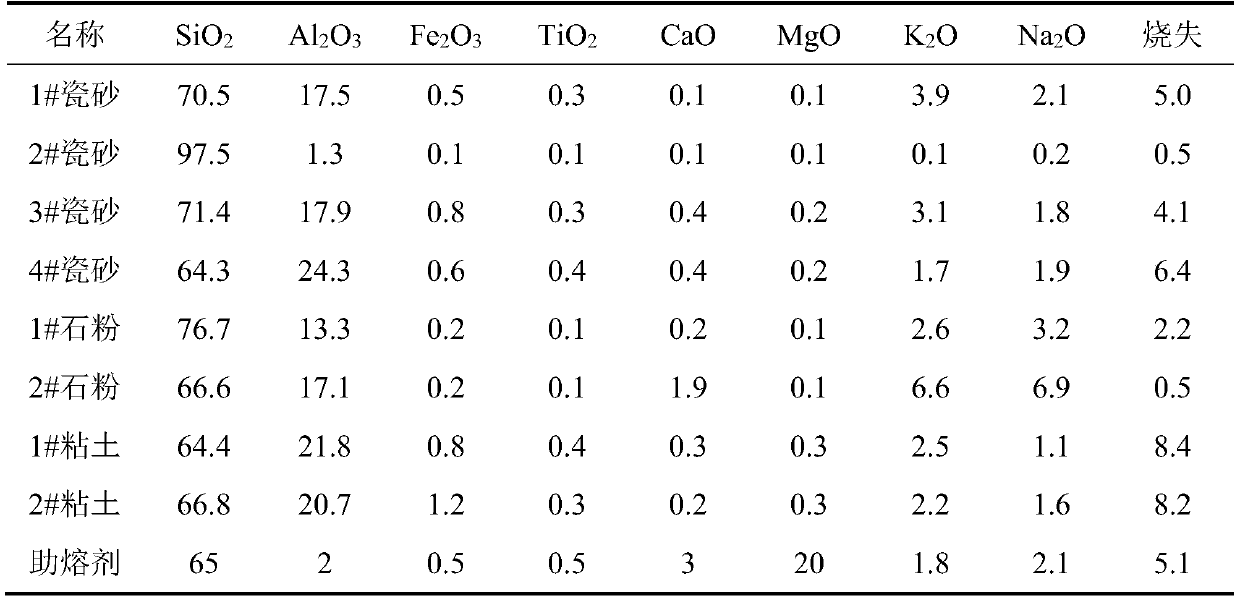

[0044] The body of the granite texture tile product is the same as the normal production of the antique brick body. The raw materials used in the formula are mainly mud, sand, and stone near the factory. The specific chemical composition analysis is shown in Table 1. Chemical composition of raw materials for granite body. Note: 1# and 2# in the table mean first and second, and so on.

[0045] Table 1 Chemical composition of raw materials for granite billets (by mass percentage)

[0046]

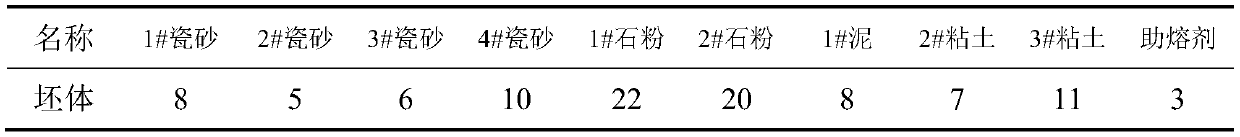

[0047] Table 2 Raw material composition of granite body (by mass percentage)

[0048]

[0049] Table 3 Body chemical composition of granite tiles (by mass percentage)

[0050]

[0051]

[0052]Prepare the green body: select corresponding proportions of 1# porcelain sand, 2# porcelain sand, 3# porcelain sand, 1# stone powder, 2# stone powder, mud, 1# clay, 2# clay, flux, and auxiliary raw materials with an additional weight percentage of 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com