An ultra-hydrophobic polymer microporous membrane and a preparing method thereof

A polymer and microporous membrane technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve problems such as damage, and achieve the effect of simple process, stable surface performance and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of superhydrophobic polymer microporous film, and it comprises the following steps:

[0029] S1, dissolving polyalkoxysilanes terminated with hydrophobic groups in an organic solvent to obtain a mixture;

[0030] S2, adding inorganic nanoparticles to the mixture to hydrophobically modify the inorganic nanoparticles to obtain an emulsion containing hydrophobically modified inorganic nanoparticles; and

[0031] S3, coating the emulsion containing hydrophobically modified inorganic nanoparticles on the surface of the polymer microporous membrane to form a hydrophobic coating to obtain the superhydrophobic polymer microporous membrane.

[0032] In step S1, the function of the polyalkoxysilane terminated with a hydrophobic group is to modify the inorganic nanoparticles hydrophobically. The polyalkoxysilanes in the polyalkoxysilanes terminated with hydrophobic groups are methyltrimethoxysilane, ethyltriethoxysilane, propylt...

Embodiment 1

[0046] (1) 5 g of methyltrimethoxysilane was dissolved in absolute ethanol, and ultrasonically treated for 10 minutes to obtain a mixture.

[0047] (2) Add 5 g of nanometer zinc oxide particles to the mixture, and ultrasonically treat it for 20 minutes to obtain an emulsion containing hydrophobically modified nanometer zinc oxide particles.

[0048] (3) The emulsion containing the hydrophobically modified nano-zinc oxide particles is evenly coated on the surface of the polyvinylidene fluoride microporous membrane formed by peeling off the non-woven fabric to form a multi-scale micro-nano structure surface by scraping, and dried , to obtain a superhydrophobic polyvinylidene fluoride microporous membrane.

[0049] A performance test was performed on the superhydrophobic polyvinylidene fluoride microporous membrane. The result is: the surface water droplet contact angle of the superhydrophobic polyvinylidene fluoride microporous membrane is 152°. The prepared superhydrophobic p...

Embodiment 2

[0051] (1) 1 g of perfluorooctyltriethoxysilane was dissolved in absolute ethanol, and ultrasonically treated for 20 minutes to obtain a mixture.

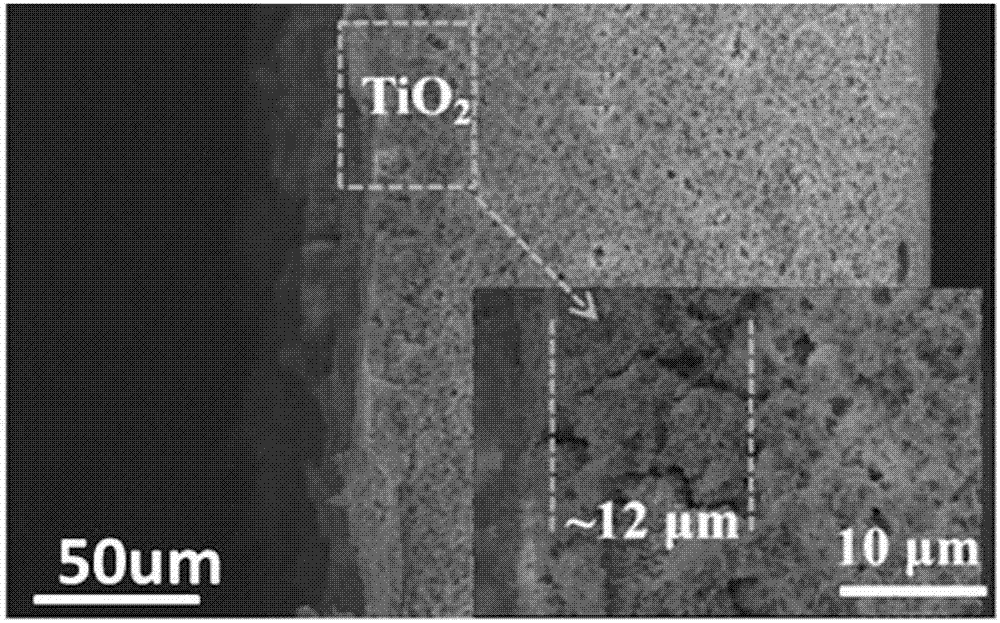

[0052] (2) Add 6 g of nanometer titanium dioxide particles to the mixture, and ultrasonically treat it for 40 minutes to obtain an emulsion containing hydrophobically modified nanometer titanium dioxide particles.

[0053] (3) The emulsion containing the hydrophobically modified nano-titanium dioxide particles is evenly coated on the surface of the polyvinylidene fluoride microporous membrane formed by peeling off the non-woven fabric to form a multi-scale micro-nano structure surface by spin coating (see figure 1 ), and dried to obtain a superhydrophobic polyvinylidene fluoride microporous membrane.

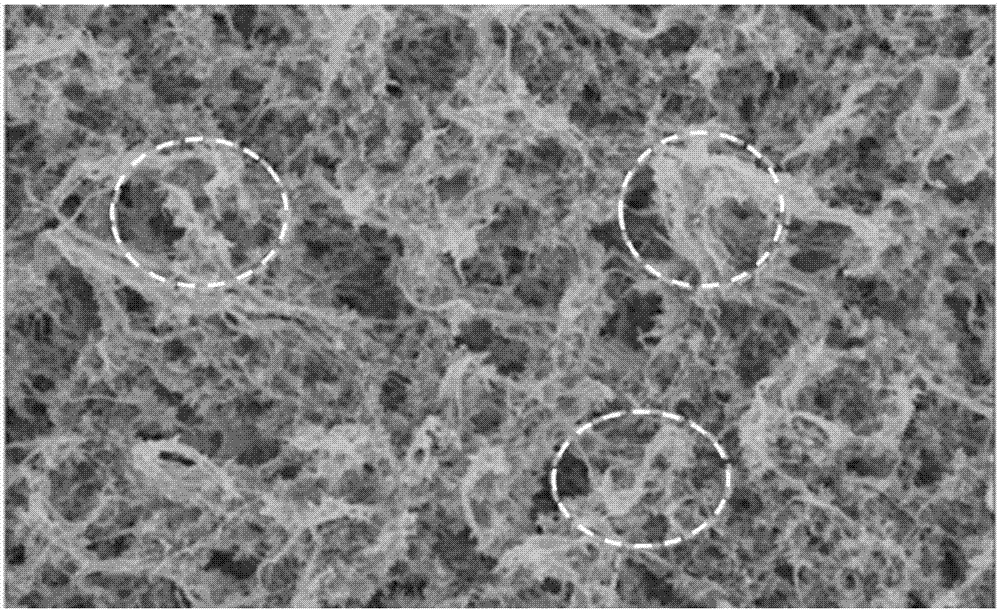

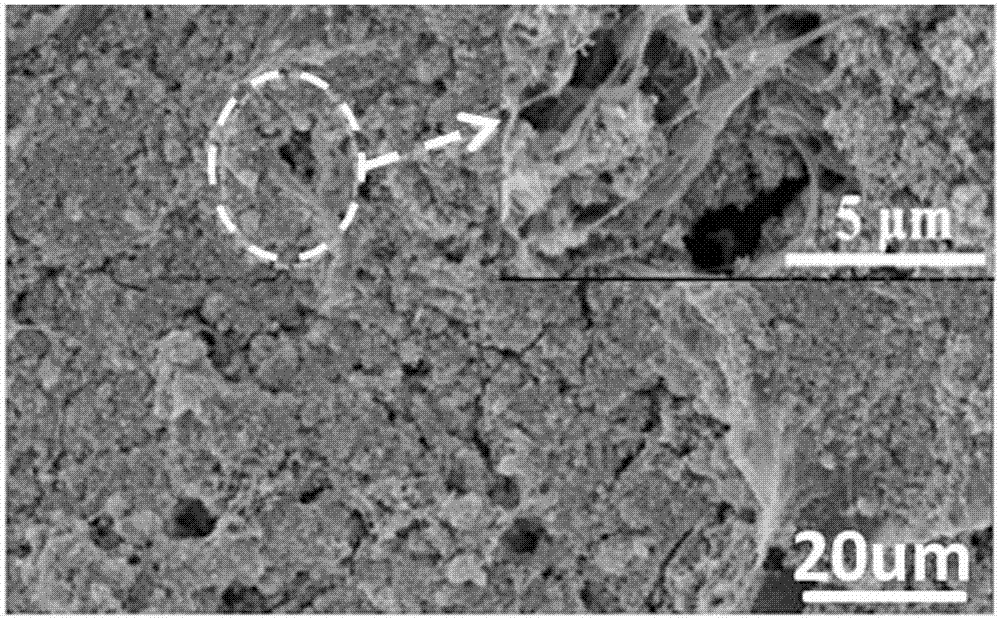

[0054] The superhydrophobic polyvinylidene fluoride microporous membrane is subjected to a morphology test, and the results are shown in figure 2 and image 3 . Depend on figure 2 It can be seen that the surface of the polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com