Method for predicting surface hardness of laser textured aluminum alloy

A technology of aluminum alloy surface and surface hardness, which is applied in laser welding equipment, testing material hardness, metal processing equipment, etc., can solve the problems of not considering the influence of material friction performance, and not establishing the mapping relationship of laser processing process parameters, etc., to achieve improvement Effect of laser texturing aluminum alloy surface on service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

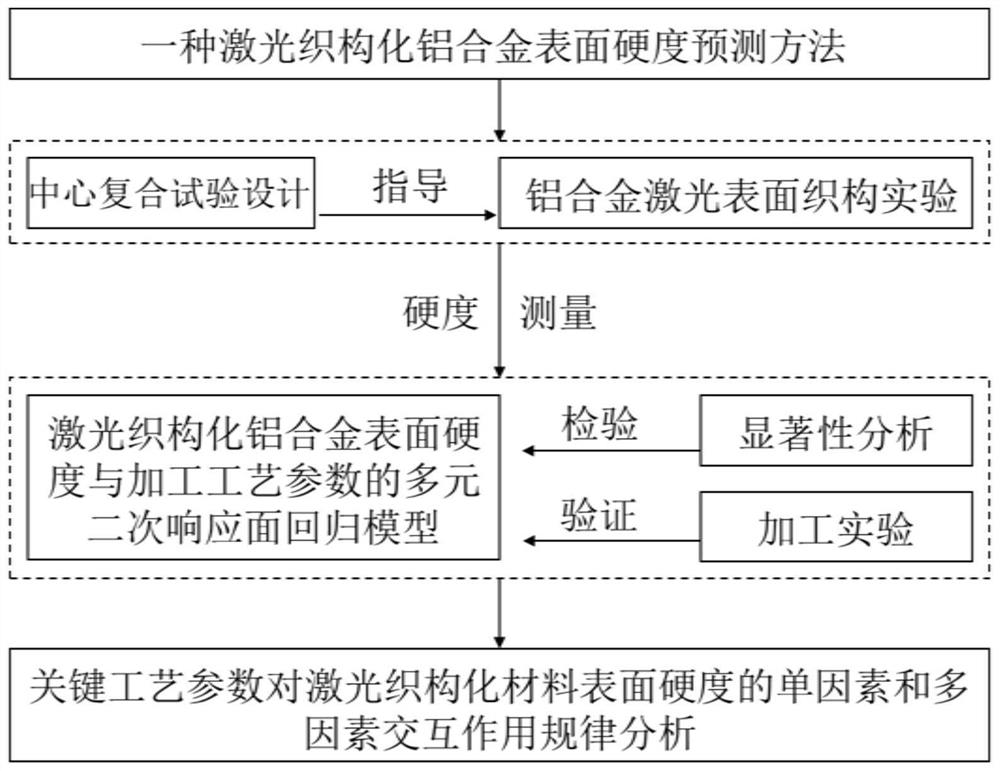

[0026] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings.

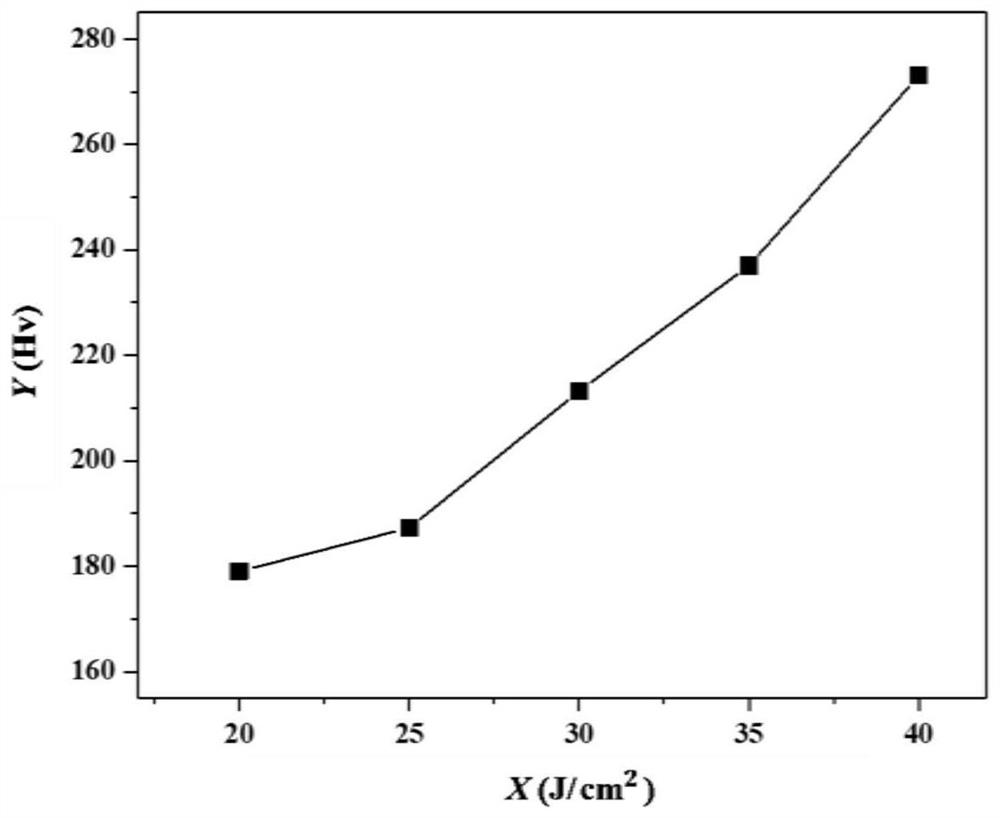

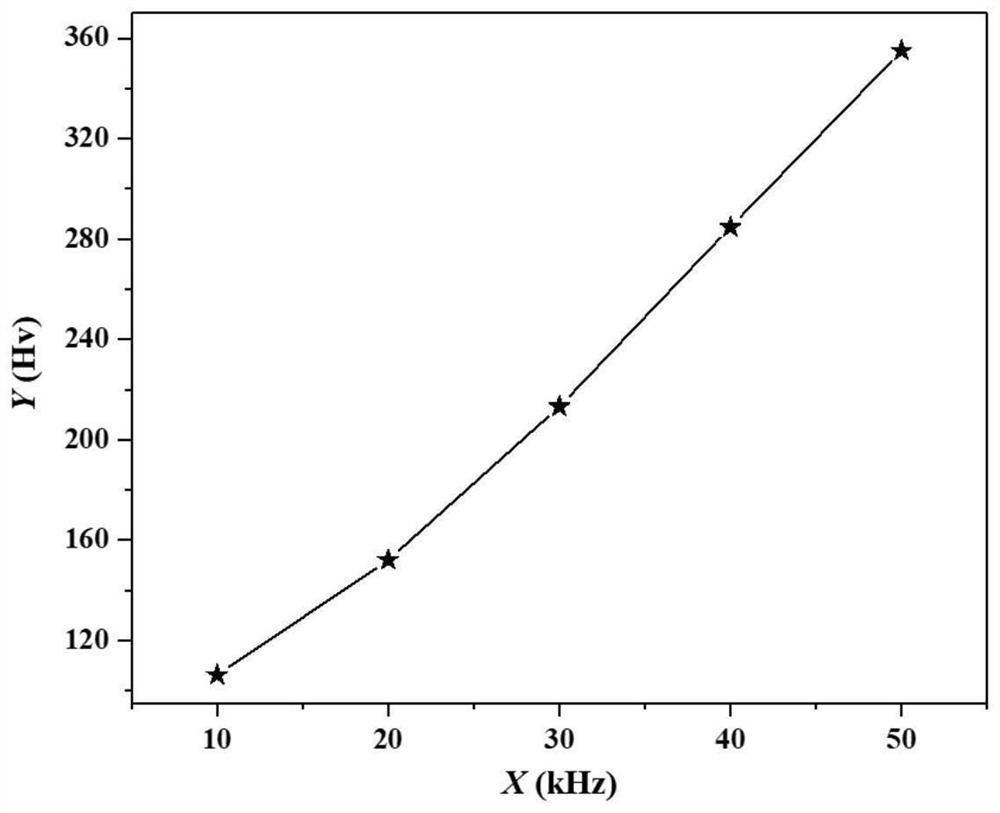

[0027] In the process of laser surface texturing, the direct interaction between the laser and the target in a short time and in a small area causes the material to melt and solidify rapidly, resulting in work hardening, which affects the tribological properties and fatigue strength of the laser textured material surface. In view of the fact that the laser processing parameters directly affect the hardness of the textured surface, and the hardness plays a crucial role in the tribological properties of the laser textured surface. Aiming at the limitations and defects of the existing technology, a method for predicting the surface hardness of laser-textured aluminum alloys was invented. Based on the central composite test design method, the laser-textured aluminum alloy surface processing experiments were carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com