Equipment and method for preparing high quality precision coating through deposition by adopting arc ion plating

An arc ion plating, high-quality technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of no breakthrough progress, ulcerative corrosion, and failure to meet the requirements of experimental standards , to achieve the effect of improving the comprehensive performance of the surface and improving the corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

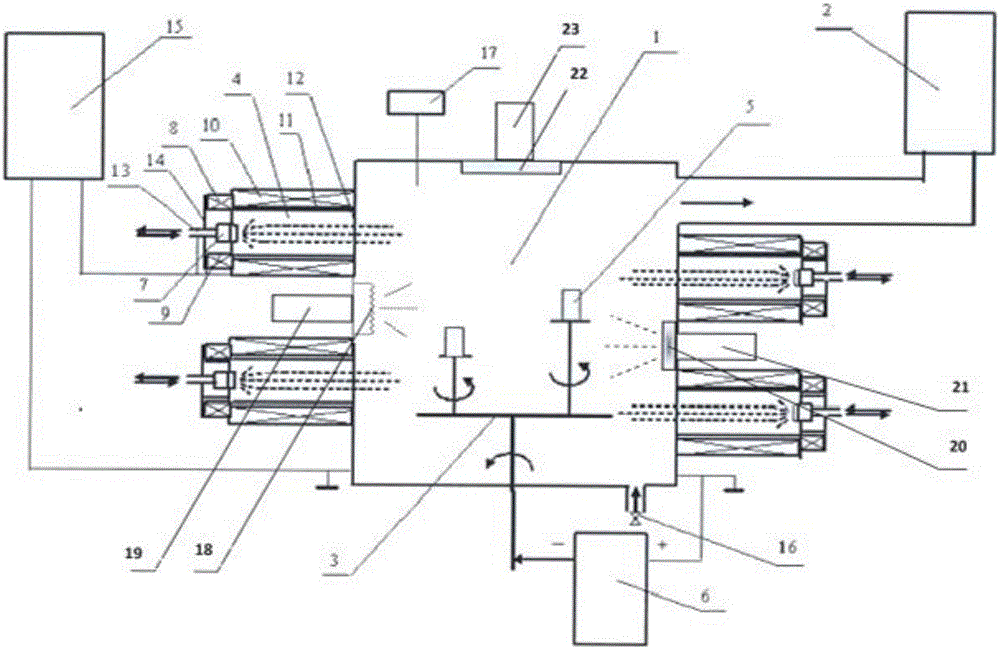

[0034] (1) On the arc source flange 12 of the vacuum chamber 1 of the arc ion plating equipment, 8 cathode arc sources 4 with a secondary electromagnetic field filter structure are installed, wherein the inner diameter of the primary coil support cylinder 9 is Φ150mm, and the length is 80mm , the winding density of the primary coil 8 is 10 turns / mm, the coil copper wire diameter is 0.8mm; the inner diameter of the secondary coil support cylinder 11 is Φ160mm, the length is 200mm, the winding density of the secondary coil 10 is 20 turns / mm, the coil The diameter of the copper wire is 1.0mm; in addition, the gas ion source 20 and its power supply 21 with a slit width of 1.3mm and a circumference of 500mm are installed on the vacuum chamber 1; Its power supply 19 is installed on the vacuum chamber; a length of 25mm with a diameter of 300mm heater 22 and its power supply 23 are installed on the vacuum chamber; finally, 4 of the 8 metal cathode targets 7 are installed as pure carbon...

Embodiment 2

[0042] (1) Install 10 cathode arc sources 4 with a secondary electromagnetic field filter structure on the arc source flange 12 of the vacuum chamber 1 of the arc ion plating equipment, wherein the inner diameter of the primary coil support cylinder 9 is Φ150mm and the length is 50mm , the winding density of the primary coil 8 is 10 turns / mm, the coil copper wire diameter is 0.8mm; the inner diameter of the secondary coil support cylinder 11 is Φ160mm, the length is 100mm, the winding density of the secondary coil 10 is 20 turns / mm, the coil The diameter of the copper wire is 1.0mm; in addition, the gas ion source 20 and its power supply 21 with a slit width of 1.3mm and a circumference of 500mm are installed on the vacuum chamber 1; Its power supply 19 is installed on the vacuum chamber; The length that is 25mm is 500mm heater 22 and power supply 23 thereof is installed on the vacuum chamber; Have 5 to be installed as pure chromium target in 10 metal cathode targets 7 at last,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com