Matte release film produced by EB curing

A technology of release film and matte surface, applied in the direction of film/sheet release liner, film/sheet adhesive, coating, etc., can solve the problem of cleanliness, flatness and antistatic, resin Different degrees of cross-linking, organic solvent volatilization and other problems, to achieve the effect of flexibility, stable emulsion performance, and increased cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

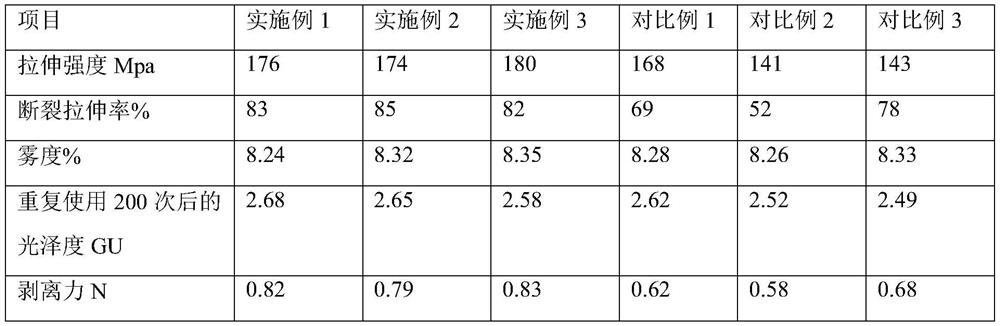

Examples

Embodiment 1

[0023] The method for preparing fog surface release film, comprises the following steps:

[0024] Weigh 12 parts of acrylate-modified polysiloxane prepolymer, 13 parts of N-butoxyacrylamide, 20 parts of natural latex, 2 parts of emulsified silicone oil emulsion, 3 parts of water-based silicone oil, and water-based zinc stearate according to parts by weight. 1 part, 4 parts of platinum-cyclovinylmethylsiloxane complex, 5 parts of ethoxyquinoline, continuously add water and stir to make the mixture uniform, and mechanically stir for 20 minutes to obtain a mixed solution. It is uniformly coated on the surface of the 125 μm PET substrate by a coater to form a release layer, wherein the blade pressure in the coater is 0.3Mpa, the coating speed is 30m / min, and the thickness of the release layer The coating temperature is 22°C and the relative humidity is 60%. The release agent layer is cured by electron beam radiation. The voltage of the electron beam is 200kv, and the dose of the e...

Embodiment 2

[0026] The method for preparing fog surface release film, comprises the following steps:

[0027] Weigh 13 parts of acrylate-modified polysiloxane prepolymer, 15 parts of N-butoxyacrylamide, 27 parts of natural latex, 2 parts of emulsified silicone oil emulsion, 4 parts of water-based silicone oil, and water-based zinc stearate according to parts by weight. 2 parts, 6 parts of platinum-cyclovinylmethylsiloxane complex, 7 parts of dibutyl hydroxytoluene, continuously add water and stir to make the mixture uniform, and mechanically stir for 20 minutes to obtain a mixed solution. It is evenly coated on the surface of the 188μm PET substrate by a coater to form a release layer, wherein the blade pressure in the coater is 0.5Mpa, the coating speed is 40m / min, and the thickness of the release layer The coating temperature is 24°C and the relative humidity is 66%. The release agent layer is cured and formed by electron beam radiation. The voltage of the electron beam is 250kv, and th...

Embodiment 3

[0029] The method for preparing fog surface release film, comprises the following steps:

[0030]Weigh 15 parts of acrylate-modified polysiloxane prepolymer, 18 parts of N-butoxyacrylamide, 35 parts of natural latex, 3 parts of emulsified silicone oil emulsion, 5 parts of water-based silicone oil, and water-based zinc stearate according to parts by weight. 2 parts, 8 parts of platinum-cyclovinylmethylsiloxane complex, and 10 parts of butylated hydroxyanisole were continuously added with water and stirred to make the mixture uniform, and mechanically stirred for 20 minutes to obtain a mixed solution. It is evenly coated on the surface of the 250μm PET substrate by a coater to form a release layer, wherein the blade pressure in the coater is 0.6Mpa, the coating speed is 50m / min, and the thickness of the release layer The coating temperature is 25°C and the relative humidity is 72%. The release agent layer is cured by electron beam radiation. The voltage of the electron beam is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com