Application and preparation method of helical carbon nano tube

A technology of carbon nanotubes and spirals, applied in the field of rubber reinforced materials, can solve the problems of complicated obtaining process and high preparation cost, and achieve the effect of simple process, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

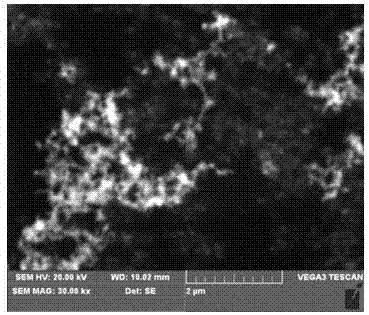

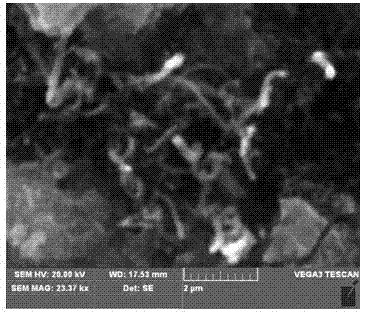

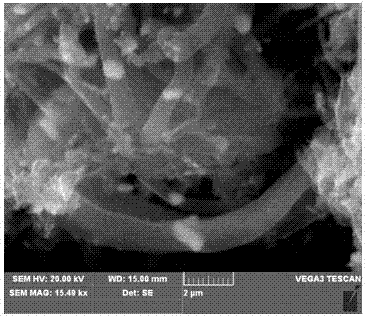

Image

Examples

Embodiment Construction

[0050] The present invention is described in further detail below in conjunction with embodiment.

[0051] The preparation method of spiral carbon nanotube of the present invention is:

[0052] One, at first carry out the preparation of catalyst:

[0053] The catalyst used in the present invention is nickel, but during the preparation, only the precursor of the catalyst nickel-nickel oxide is obtained, and the nickel oxide is required to be nano-sized, and the nickel oxide can be reduced by hydrogen in the subsequent preparation process of the spiral carbon nanotube. Nickel oxide can be prepared by two methods to obtain two different forms of nickel oxide, one is film-like nickel oxide, and the other is powdery nickel oxide. The specific preparation method is as follows:

[0054] The preparation method of the film-shaped nickel oxide is as follows: the film-shaped nickel oxide is directly oxidized on the nickel sheet. Divide the metal nickel sheet into small squares of 10mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com