Microlite environment-friendly base material and multifunctional plate

A technology of microcrystalline stone and microcrystalline stone powder, applied in the direction of floor, building, building structure, etc., can solve the problems of poor moisture-proof, fire-proof, anti-fouling performance, heavy material, inconvenient construction, etc., and reduce labor labor. And construction cost, improve thermal insulation performance, improve the effect of moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

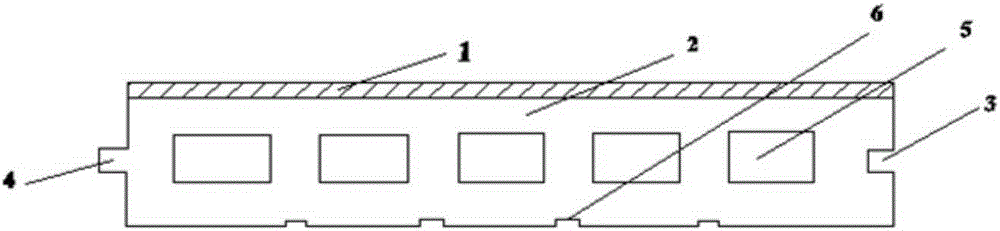

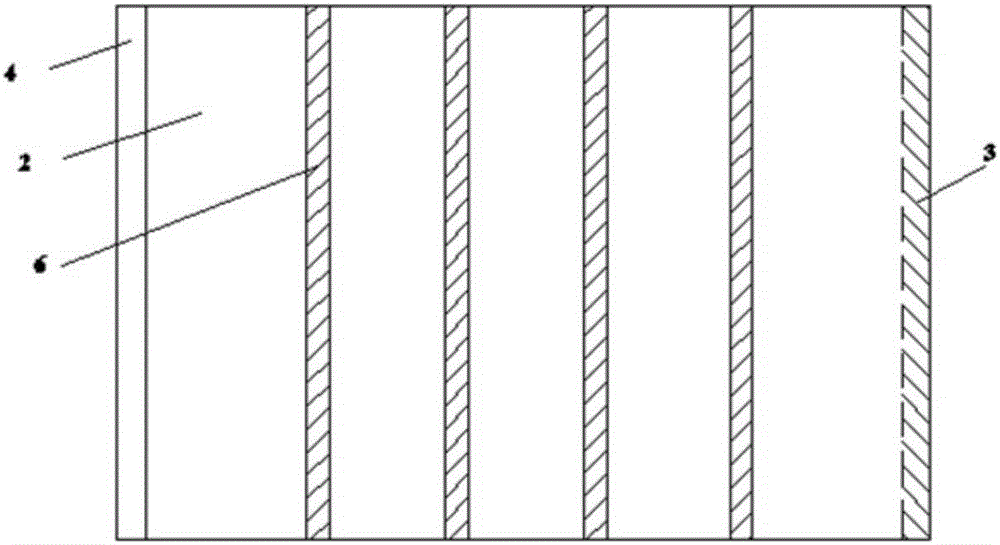

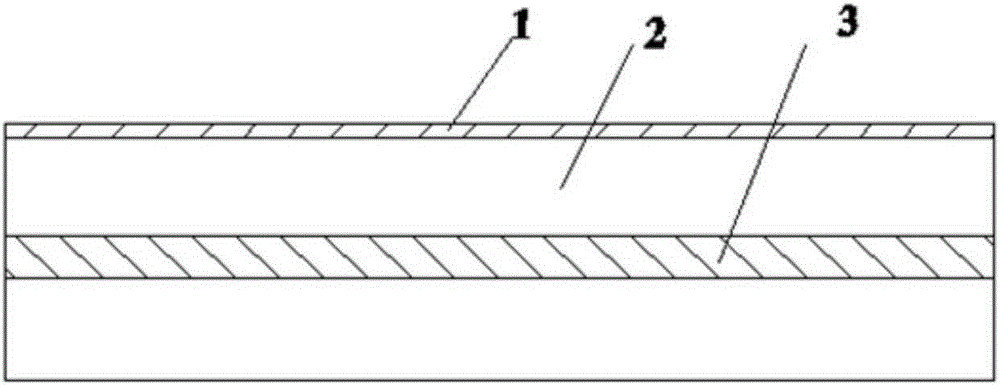

Image

Examples

Embodiment 1

[0021] A kind of microcrystalline stone environment-friendly base material, its composition and weight percent are: microcrystalline stone powder 30-60%; PVC resin 8-20%; Composite stabilizer: 4-10%; CPE1-10%; Kaolin: 1- 10%; fly ash 1-10%; aluminum oxide: 1-5%; magnesium hydroxide: 1-10%; antimony trioxide: 1-5%; stearic acid: 1-8%; DOP: 4 -6%; antistatic powder: 1-10%; aluminum tripolyphosphate: 1-10%.

Embodiment 2

[0023] A kind of microcrystalline stone environment-friendly base material, its composition and weight percent are: microcrystalline stone powder 40%; PVC resin 16%; composite stabilizer 6%; CPE 6%; kaolin: 1%; fly ash 2%; alumina 3%; magnesium hydroxide: 3%; antimony trioxide: 3%; stearic acid: 3%; DOP: 5%; antistatic powder: 9%; aluminum tripolyphosphate: 3%.

Embodiment 3

[0025] A kind of microcrystalline stone environment-friendly base material, its composition and weight percent are: microcrystalline stone powder 40%; PVC resin 16%; composite stabilizer 6%; CPE 6%; kaolin: 1%; fly ash 2%; alumina 3%; Magnesium Hydroxide: 3%; Antimony Trioxide: 3%; Stearic Acid: 3%; DOP: 5%; Aluminum Tripolyphosphate: 3%; Tin Dioxide: 5%; Zinc Oxide: 3% , magnesium oxide: 1%

[0026] The novel multi-functional board that above embodiment is made, detects indexes such as its moisture-proof performance, anti-ant performance, anti-static, fireproof performance and thermal conductivity, test method and result are as follows:

[0027] (1) Fire performance

[0028] With reference to GB / T8624-2012, GB / T5464-2010, GB / T14402-2007, the performance of the multifunctional board made of the microcrystalline stone environmental protection substrate in Example 1-3 is as follows:

[0029]

[0030] (2) Anti-static

[0031] Referring to the provisions of SJ / T11236-2001 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com