Electromagnetic oven without microlite board

A technology of induction cooker and microcrystalline plate, which is applied in the field of induction cooker, can solve the problems of restricting product promotion and application, ineffective positioning, high cost of microcrystalline plate, etc., and achieve the effect of lowering temperature, simple and reasonable structure, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

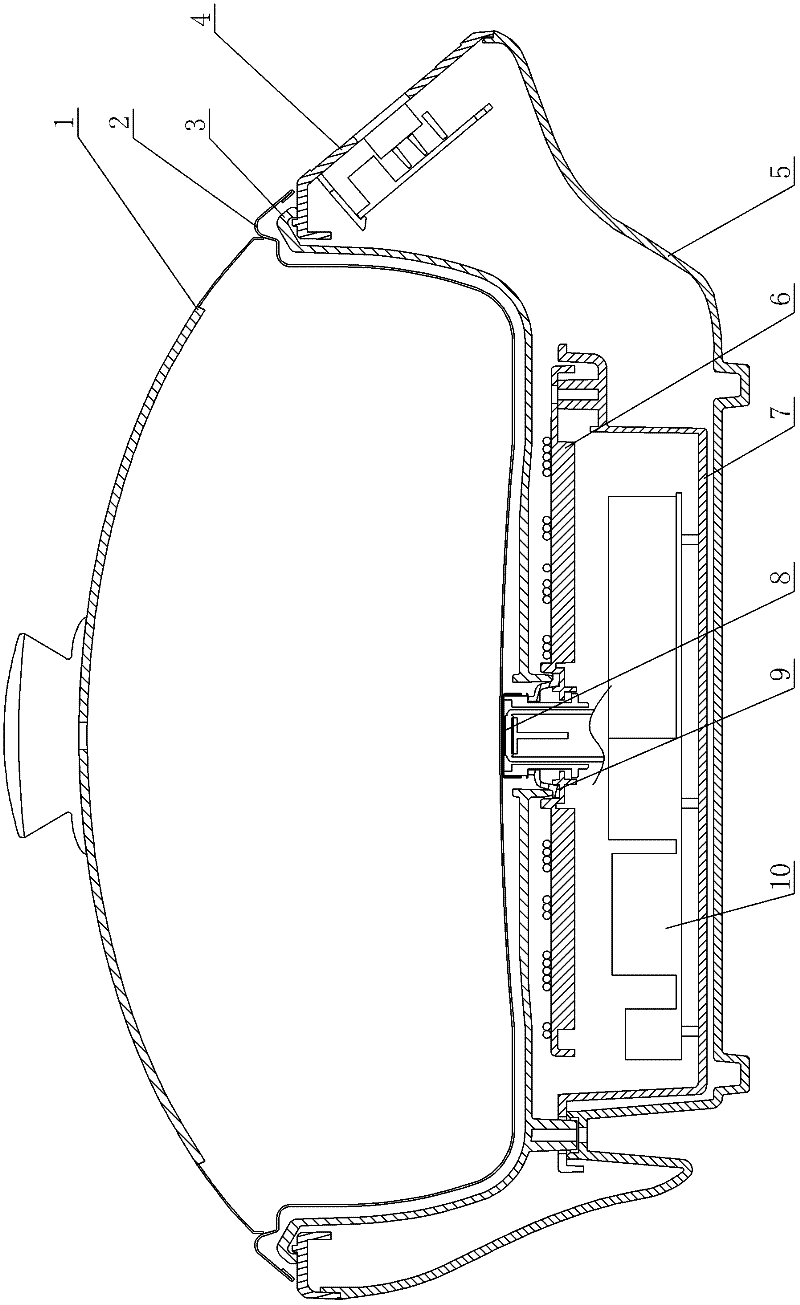

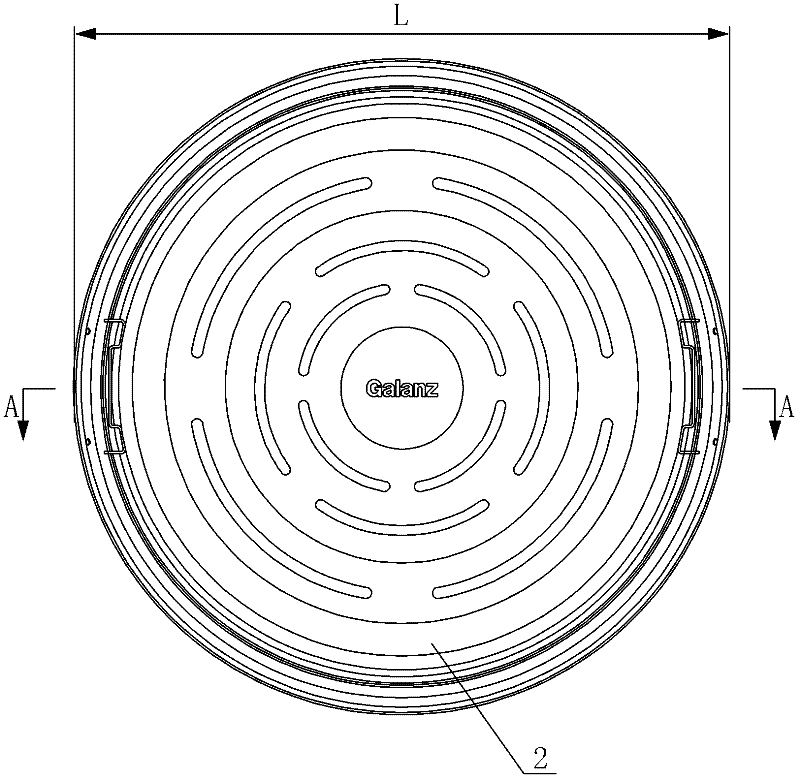

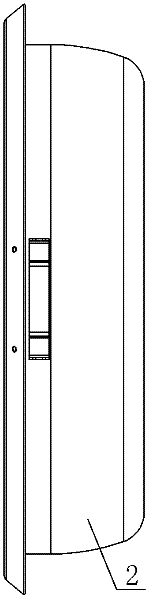

[0021] see Figure 1-Figure 4 , a microcrystalline plate-free induction cooker, comprising a base 5 and a control panel 4 thereof, the control panel 4 is arranged on one side of the base 5, and the base 5 is provided with a power supply box 7 electrically connected to the control panel 4. The base 5 is provided with a heat preservation cover 3 , and the heat preservation cover 3 is located on the top of the base 5 . The inner recess of the heat preservation cover 3 is provided with a pot liner assembly, the heat preservation cover is bowl-shaped, and the outer edge of the heat preservation cover is provided with a fixed edge. An annular boss is arranged at the corresponding position of the base 5 and the fixed side, and the heat preservation cover is suspended on the base 5 and fixed with it. The heat preservation cover and the base 2 jointly constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com