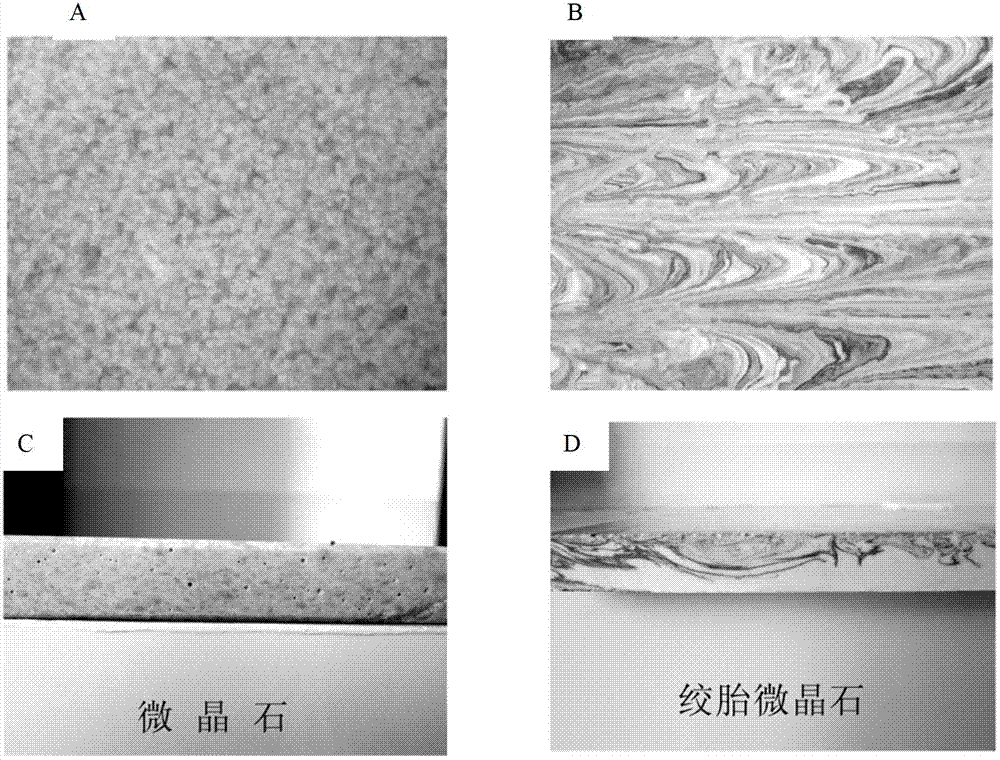

Microlite with twistable glaze, and production method and special-purpose equipment

A technology of microcrystalline stone and twist tire, which is applied in the field of building ceramic materials, can solve the problems of inability to form a through texture, the inability to create a delicate, smart, and elegant decorative atmosphere of natural stone, and the lack of smart patterns, etc., to achieve excellent anti-pollution Excellent durability and weather resistance, crystal clear and soft surface luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

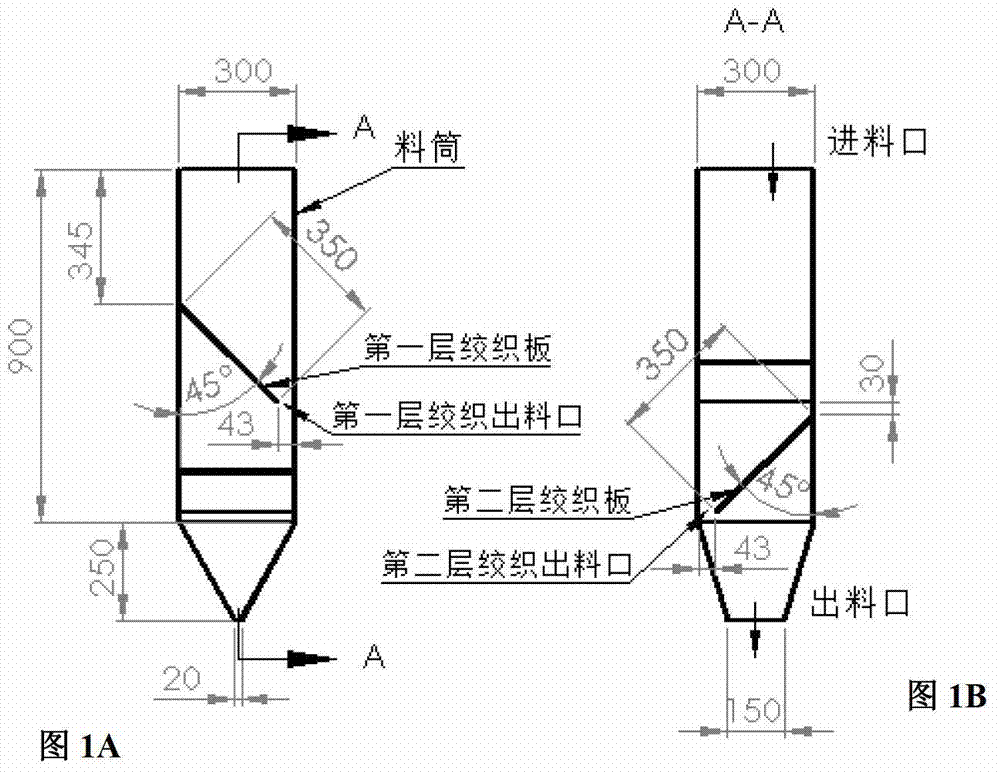

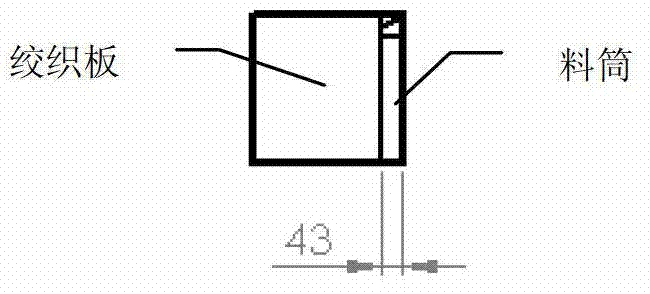

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: grouting method produces twist tire microcrystalline stone

[0062] Ingredients: 97 kg of tempered glass particles after one firing of microcrystalline stone; 3 kg of starch; four kinds of coloring materials: red, yellow, white and green.

[0063] Production method: (1) Grind 97 kg of tempered glass particles and 3 kg of starch together with a mill, pass through 150 meshes to form a white billet, mix 29 kg of white billet with 1 kg of green color material, add 20 kg of water, 14.5 Add 10 kg of water after mixing 1 kg of white blank with 0.5 kg of yellow color material, mix 14.5 kg of white blank with 0.5 kg of red color material, add 10 kg of water, add 28 kg of water to the remaining 42 kg of white blank, and stir separately to obtain red manganese red Mn -A1, the yellow is spectrum yellow Pr-Si-zr, the white is the mud base material, and the green is chrome green Cr-A1 four colors of mud.

[0064] (2) With white mud as the main material, the red, yellow...

Embodiment 2

[0068] Embodiment 2: The grouting method produces twist tire microcrystalline stone handicraft

[0069] Ingredients: 97 kg of microcrystalline stone raw materials; 3 kg of starch; the color materials include vanadium zirconium blue V-zr-Mn for blue, manganese red Mn-A1 for red, mud base material for white, and chrome green Cr-A1 for green Four kinds.

[0070] Production method: (1) Grind 97 kg of microcrystalline raw material and 3 kg of starch together with a mill to form a white billet through 150 meshes, take 29 kg of white billet and 1 kg of blue color, mix them with 20 kg of water, 14.5 kg Mix the white blank with 0.5 kg of red color material and add 10 kg of water, take 14.5 kg of white blank and 0.5 kg of pink color material, mix with 10 kg of water, add 28 kg of water to the remaining 42 kg of white blank, and stir separately to obtain blue, red, white and green Four colors of mud (according to this design, red can be mud).

[0071] (2) With white mud as the main mat...

Embodiment 3

[0087] Embodiment 3: Mud kneading method produces twist tire microcrystalline stone

[0088] Ingredients: 97 kg of microcrystalline glass particles; 3 kg of starch; three types of pigments: green as chrome green Cr-A1, yellow as orange Sb-Ti-Cr, and white as mud base.

[0089] Production method: (1) Grind 97 kg of microcrystalline glass particles and 3 kg of starch together with a mill to 150 meshes to form a white billet, mix 29 kg of white billet with 1 kg of gray color material, add 7.5 kg of water, and take 14.5 Mix one kilogram of white blank with 0.5 kilogram of orange coloring material and add 3.75 kilograms of water, add 56.5 kilograms of white blank and add 14 kilograms of water, stir respectively to obtain green, yellow and white mud.

[0090] (2) With white mud as the main material, the green and yellow mud are kneaded into strips with a width of 3cm, a thickness of 1cm, and a length of 80cm, and then arranged in a curved shape, on the white mud of 80×80×2cm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com