Method for solidifying microlite by impulse current liquid surface disturbance

A technology of pulse current and liquid level, applied in the field of metal solidification, can solve problems such as high cost, reduced plasticity, and reduced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

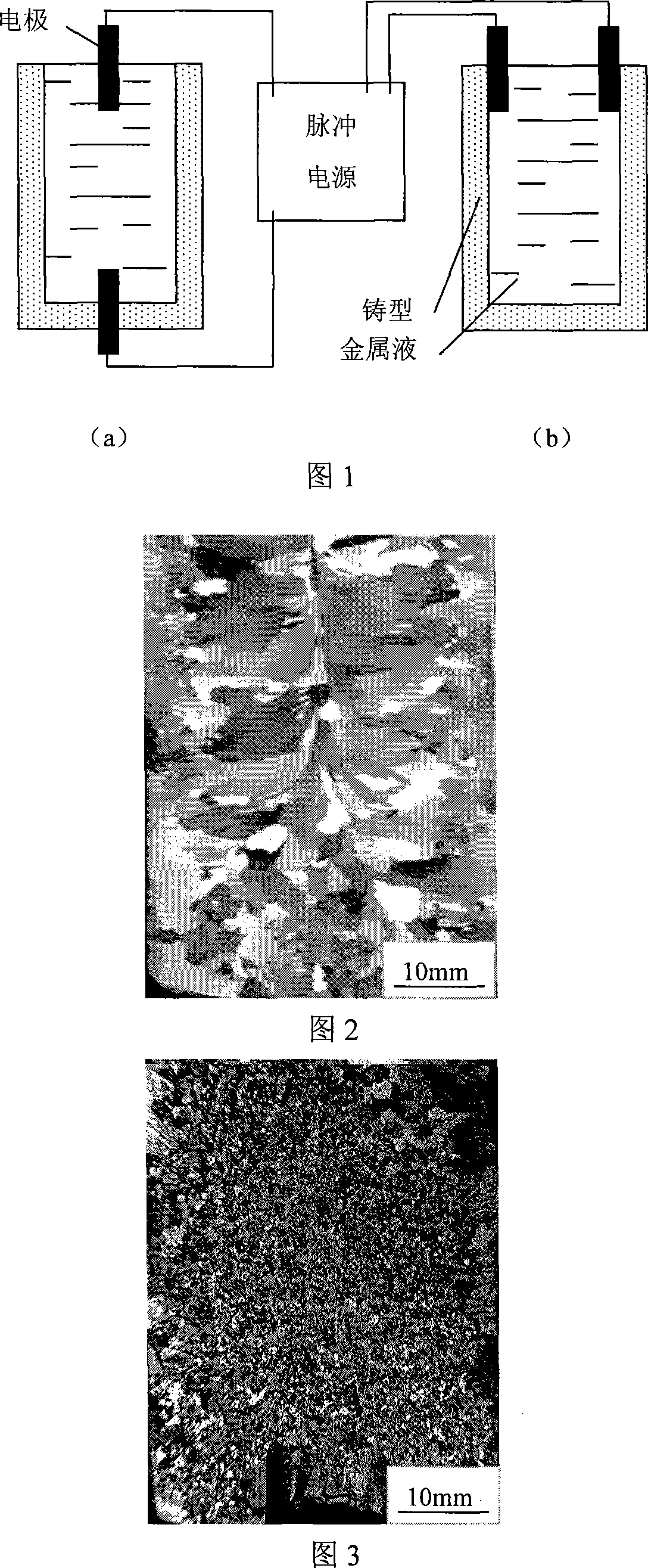

[0025] The material of this embodiment is industrial pure aluminum with a purity of 99.7wt.%. The casting mold is a water glass sand dry mold, and the casting size is Φ40×140mm. Disturbance treatment in the nucleation stage and the whole process of solidification are respectively carried out. In order to enhance the contrast, Fig. 2 shows the macrostructure of pure aluminum without pulse current liquid level disturbance, and Fig. 3 shows the macrostructure of pure aluminum treated with pulse current by vertical electrodes (current peak value is 2000A, pulse frequency is 800Hz).

[0026] The pulse current liquid level disturbance treatment in the nucleation stage, the specific process is as follows: first, the metal is melted into a liquid, and when the molten metal is overheated at 180°C, it is poured out of the furnace, and two parallel electrodes are inserted from above the melt 30mm below the liquid level of the metal, from The thermal analysis curve of the online detection ...

Embodiment 2

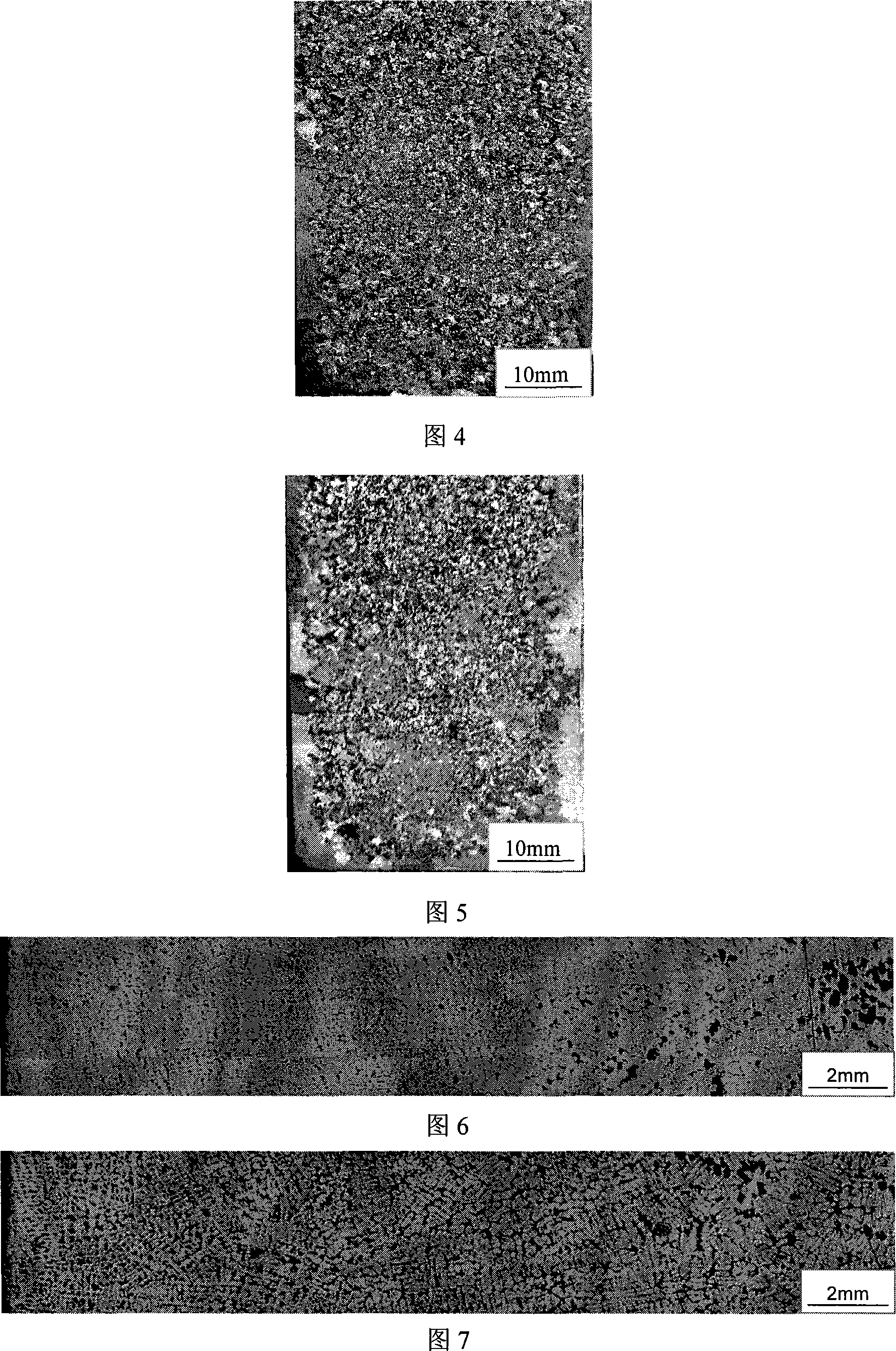

[0030] High-carbon chromium bearing steel is used as the experimental material, and its composition is C=0.80~0.96%, Si=0.20~0.35%, Mn=0.3~0.5%, P<0.025%, S<0.02%, Cr=1.35~1.50% , Ni+Cu<0.52%. In order to ensure the consistency of molten metal composition, pouring temperature and cooling conditions, and to ensure the comparability of experimental results, the experimental scheme of "simultaneous pouring and split filling" was adopted. The molten metal passes through the distribution groove and flows into the sample cavities of the same size respectively at the same time. The sample size is Φ50mm×180mm. The casting mold adopts the water glass sand dry type. The specific process is as follows: the Φ40 bar is remelted in an intermediate frequency induction furnace, and finally deoxidized with 0.2% aluminum before being released from the furnace. The pouring temperature is 1650°C (overheating 180°C). After the pouring is completed, insert two parallel electrodes from above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com