Patents

Literature

35results about How to "Color effects do not exist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

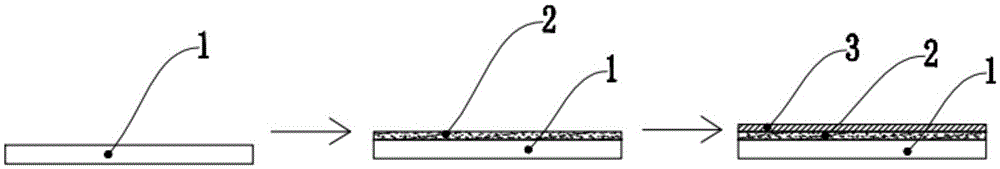

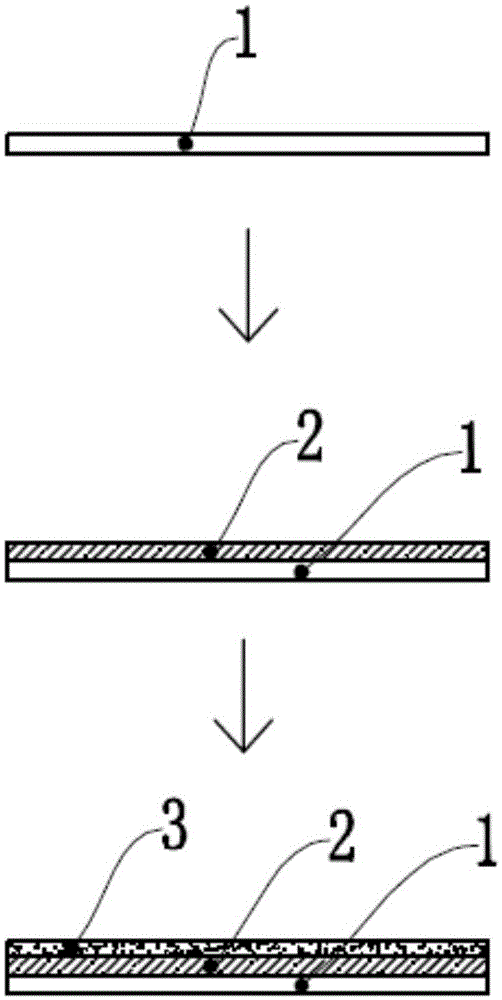

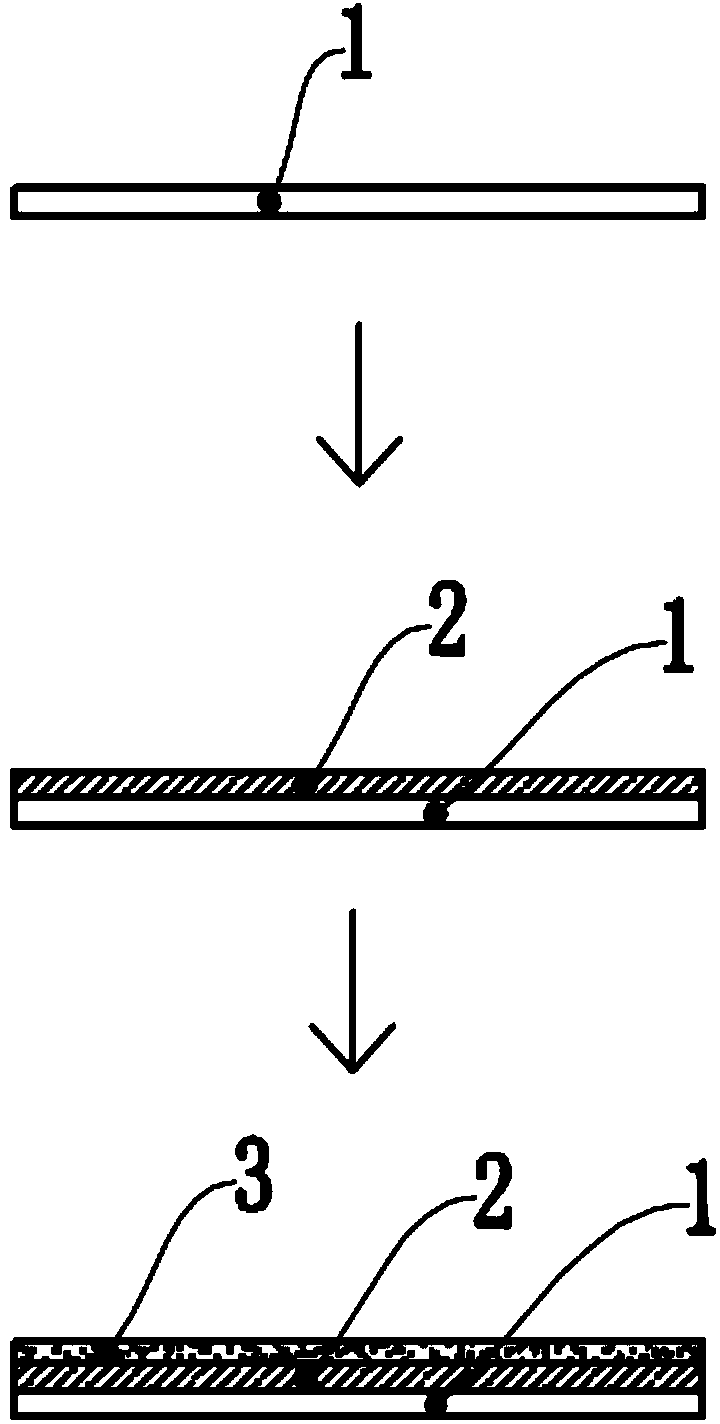

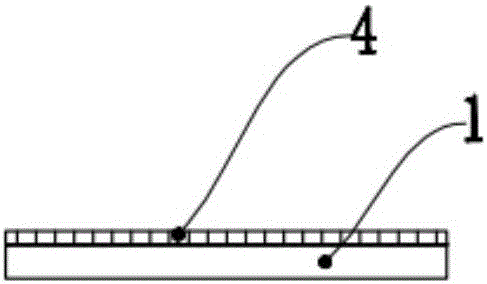

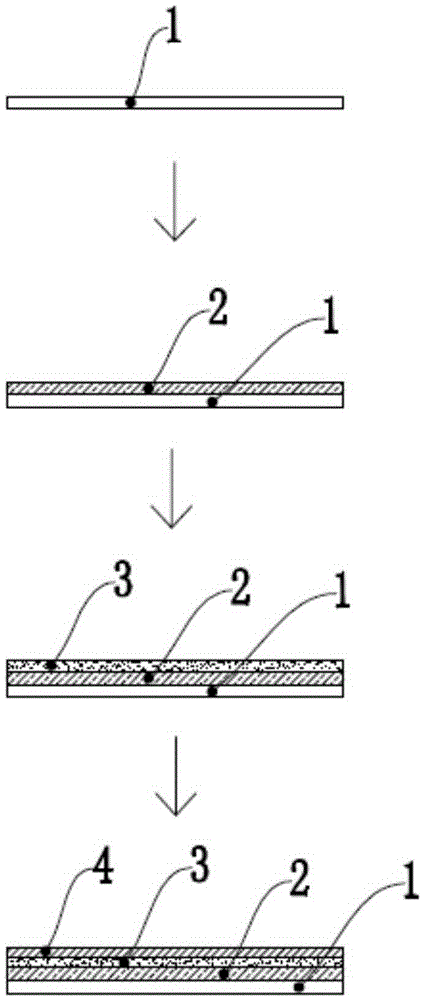

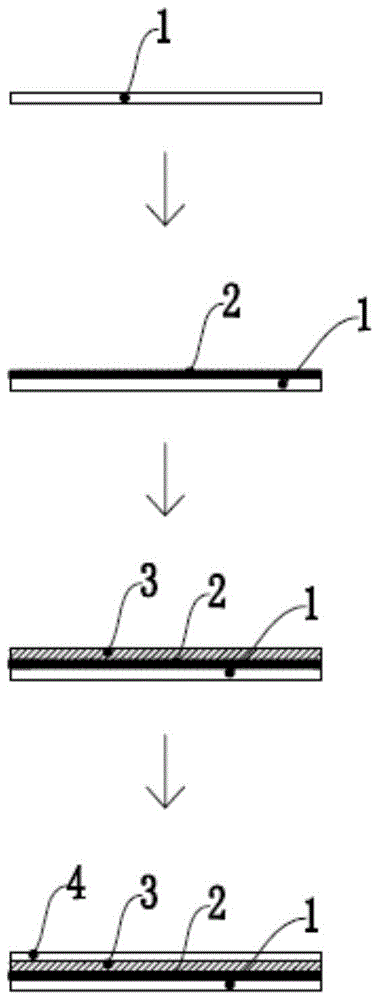

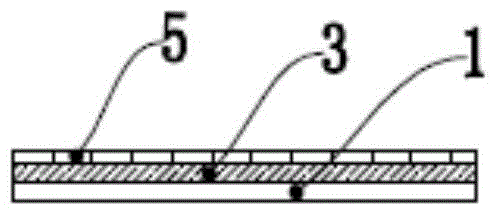

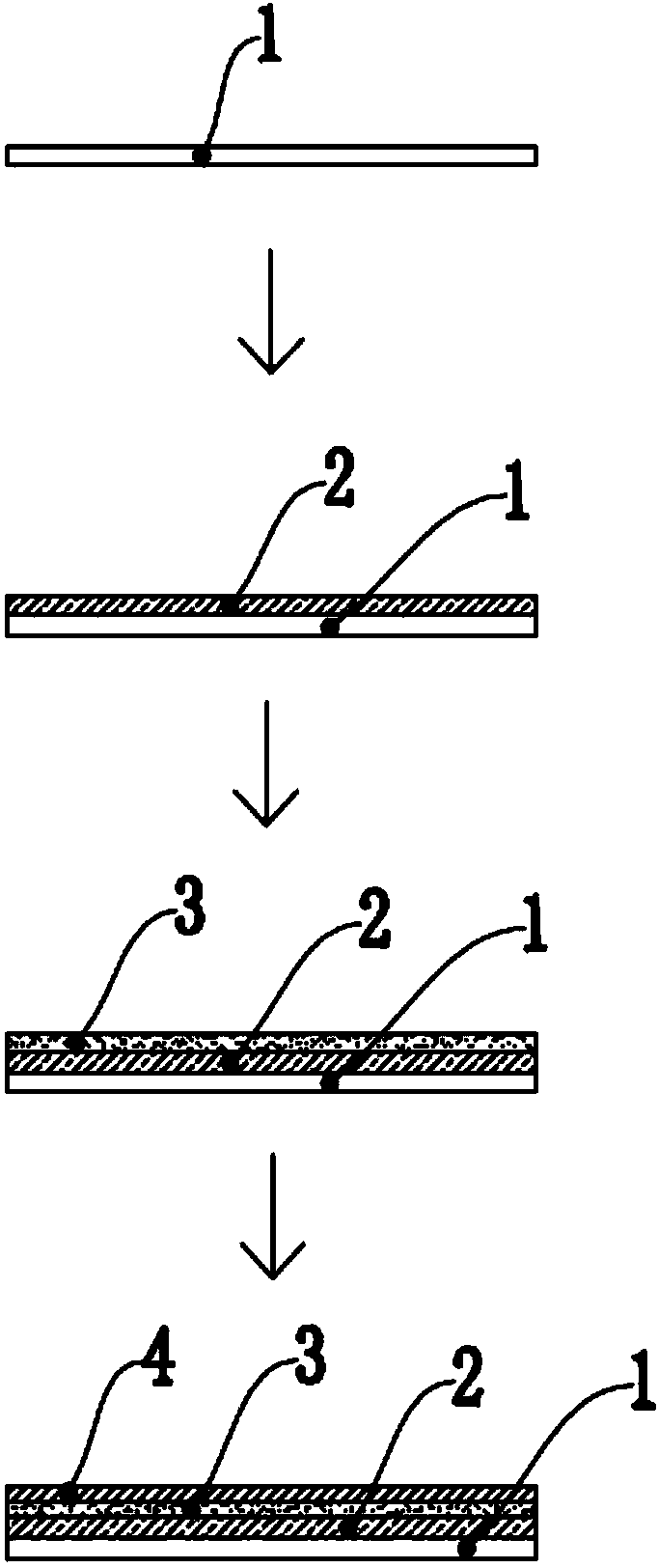

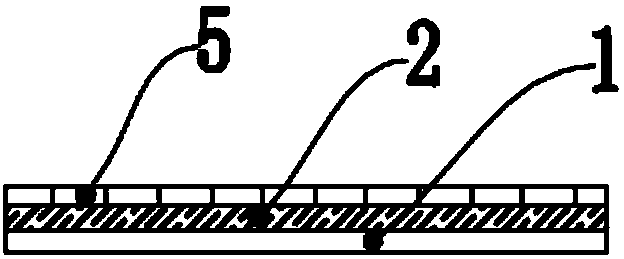

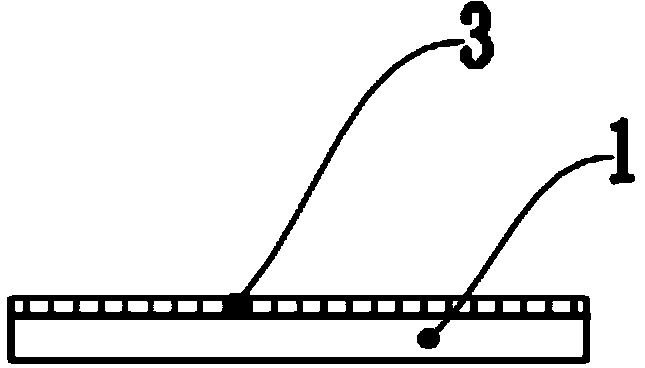

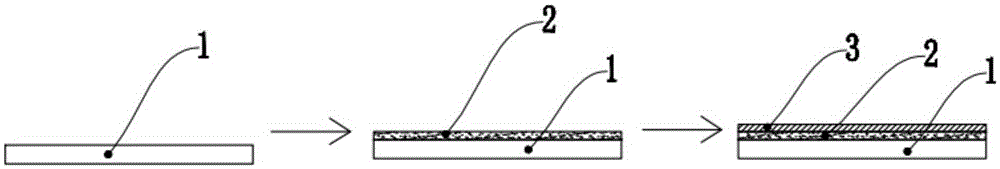

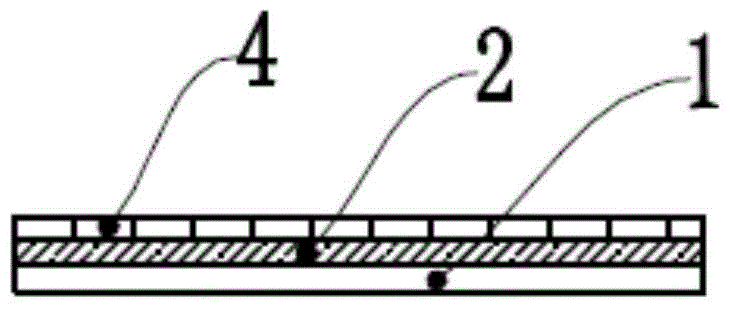

Green brick of single fired glass ceramic composite board

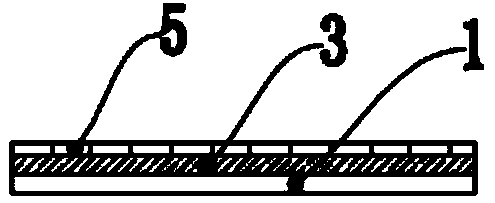

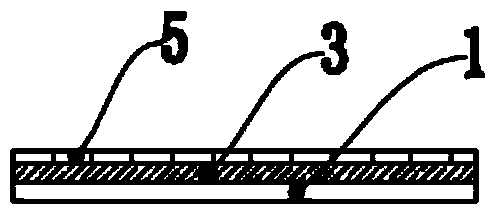

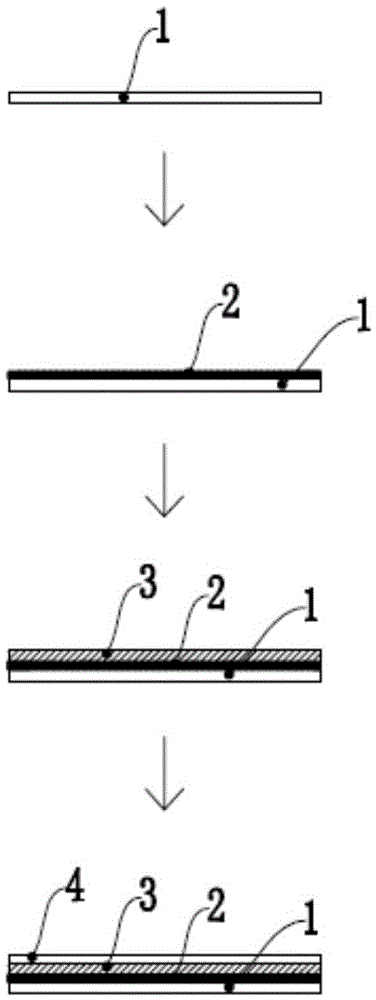

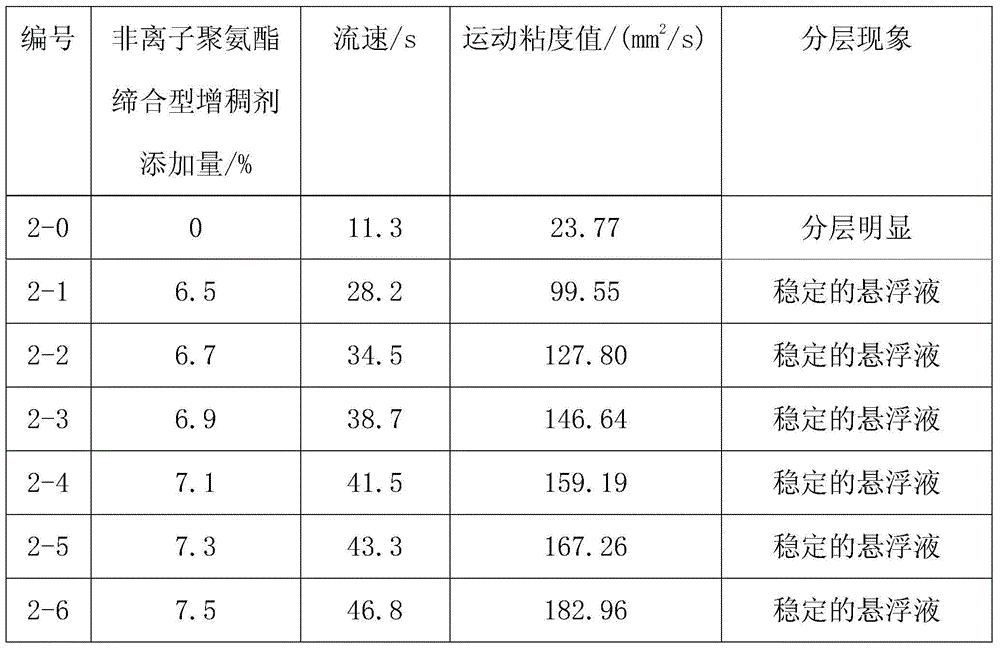

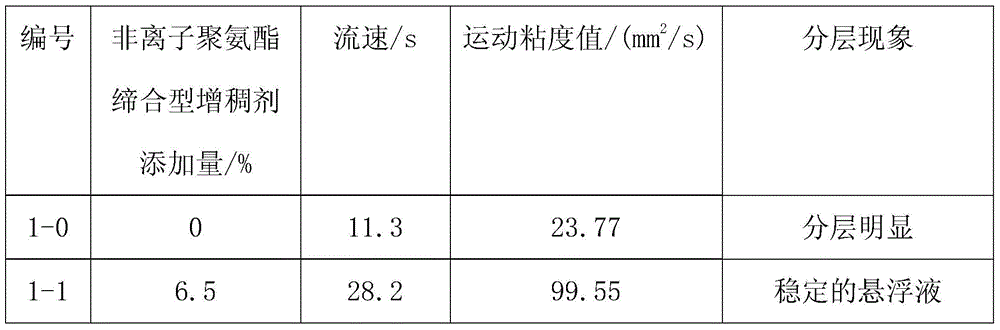

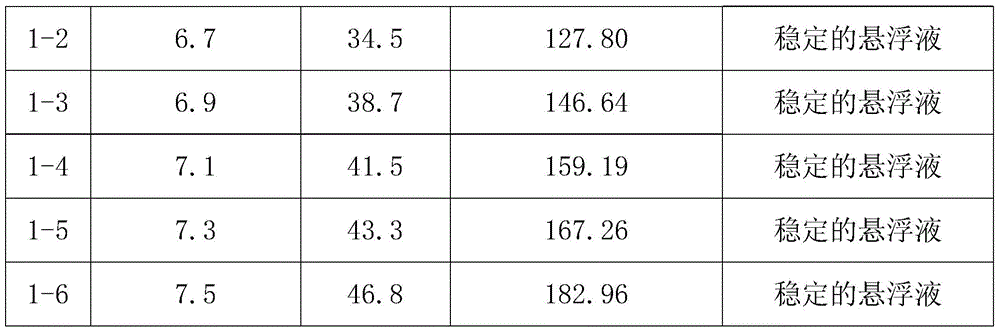

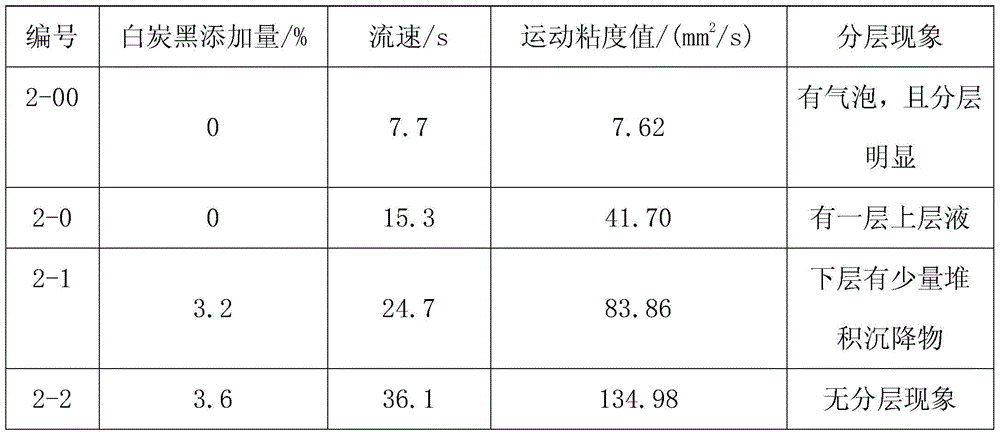

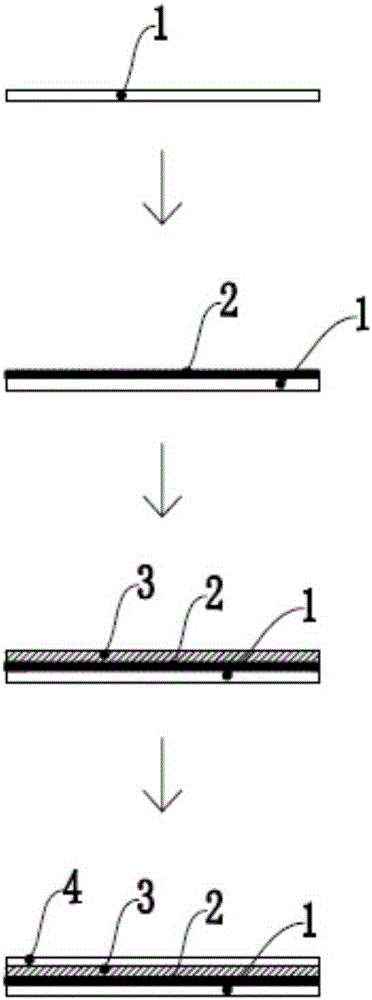

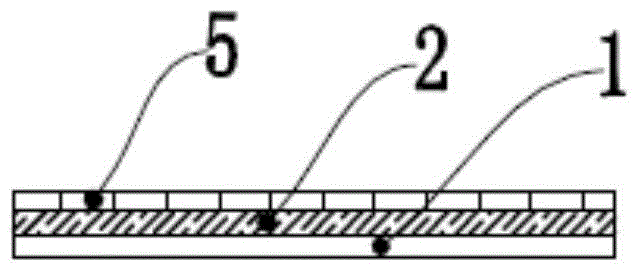

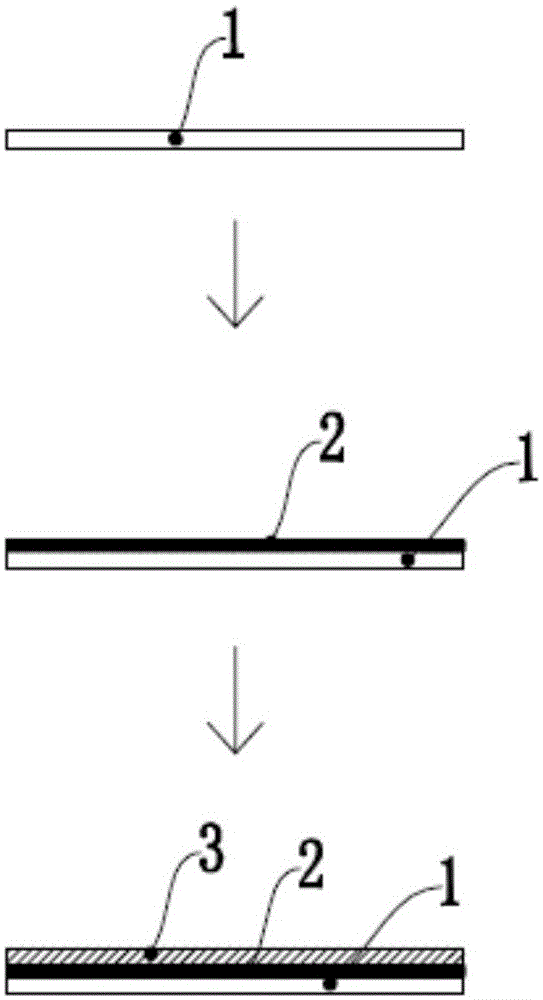

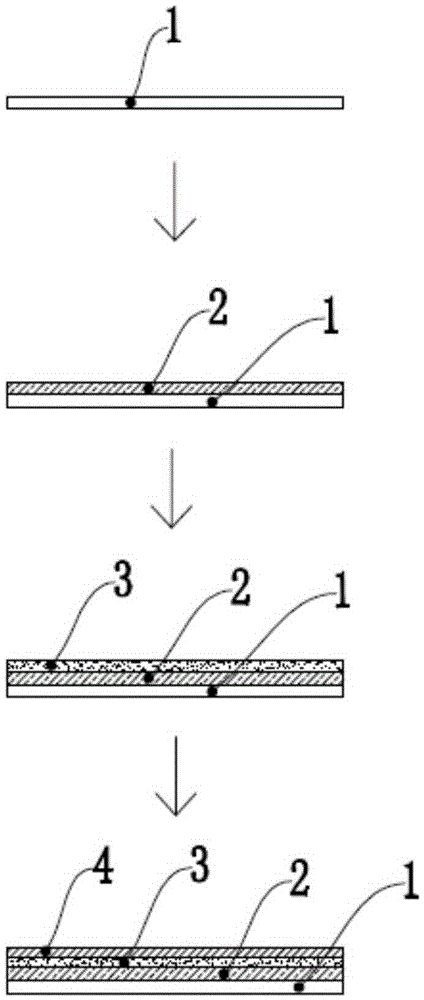

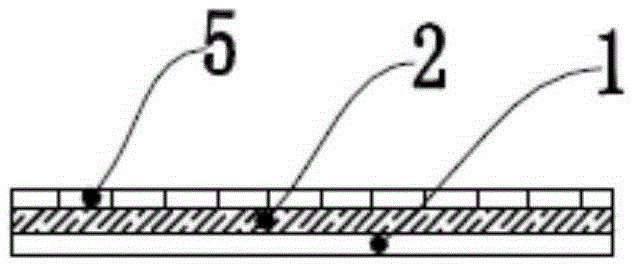

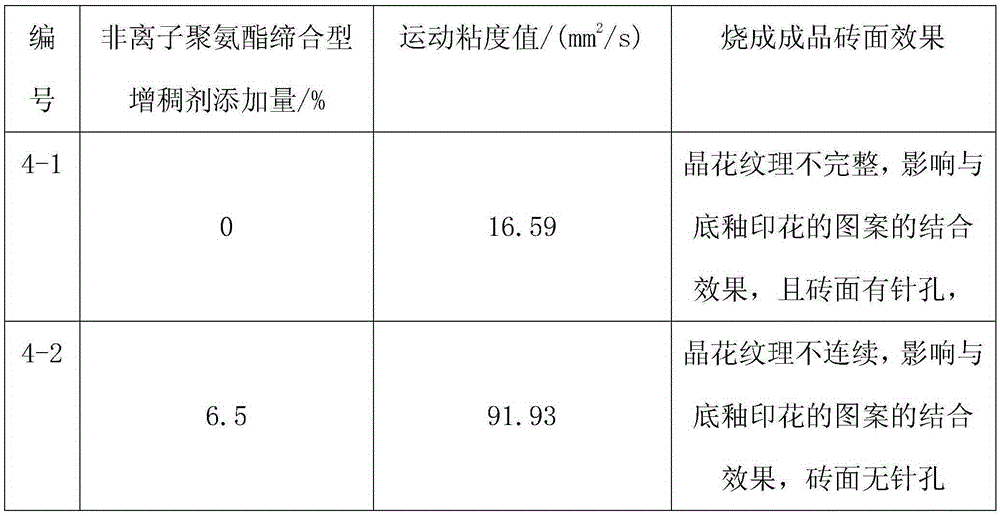

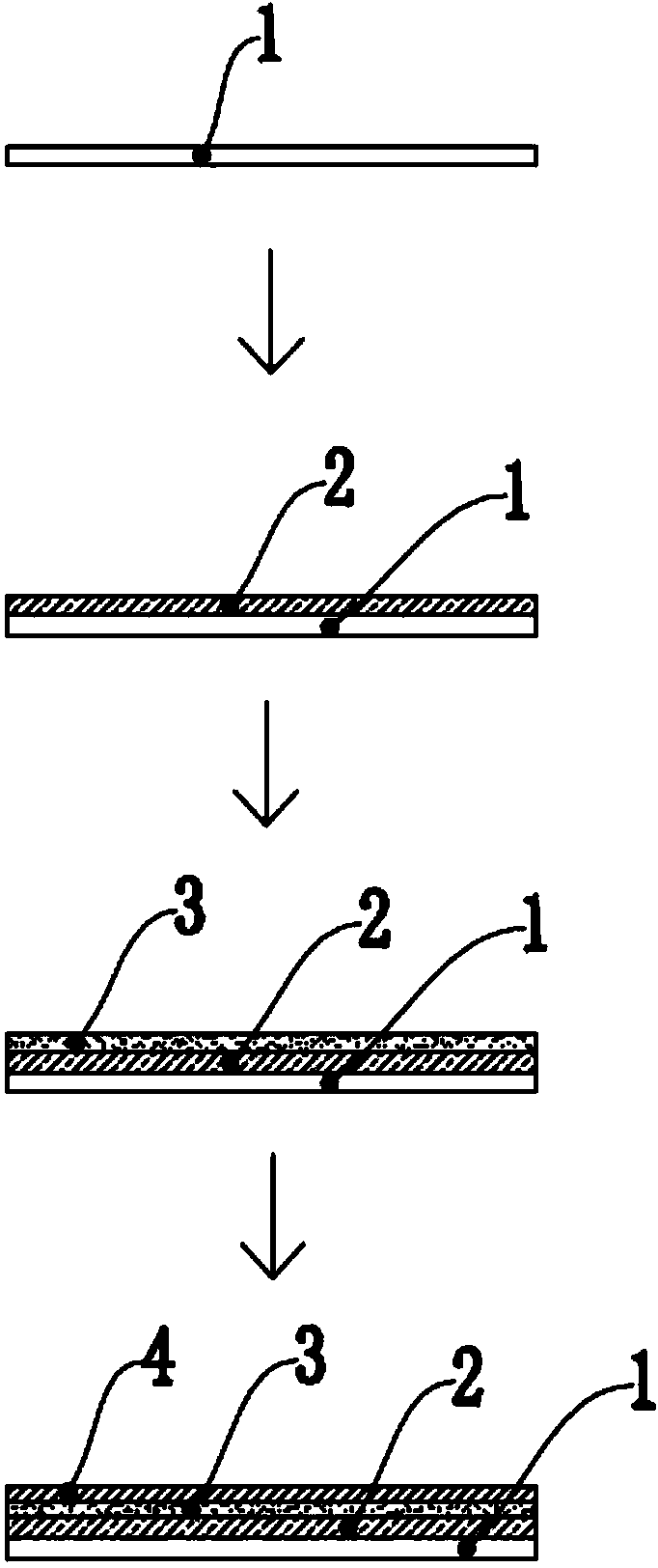

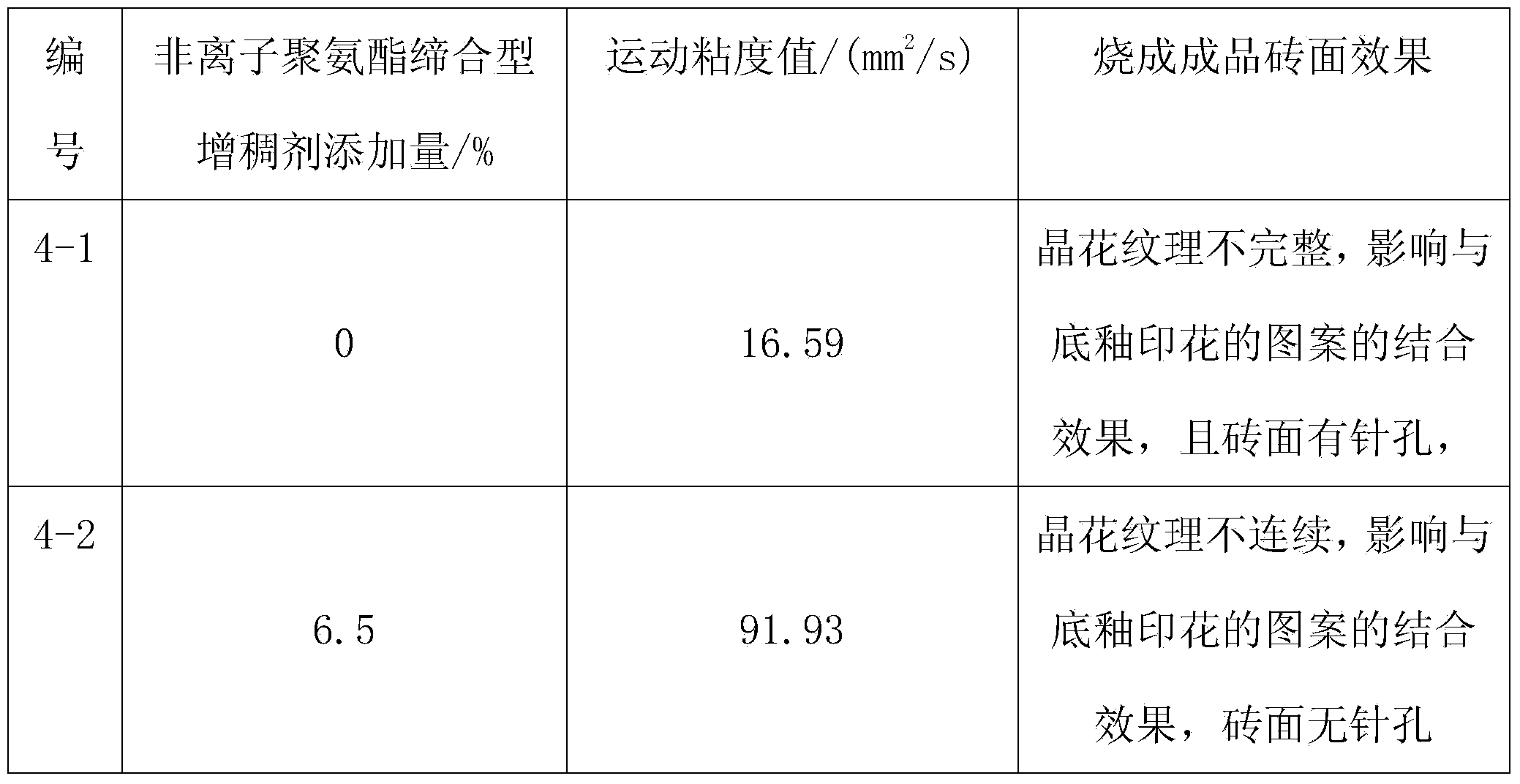

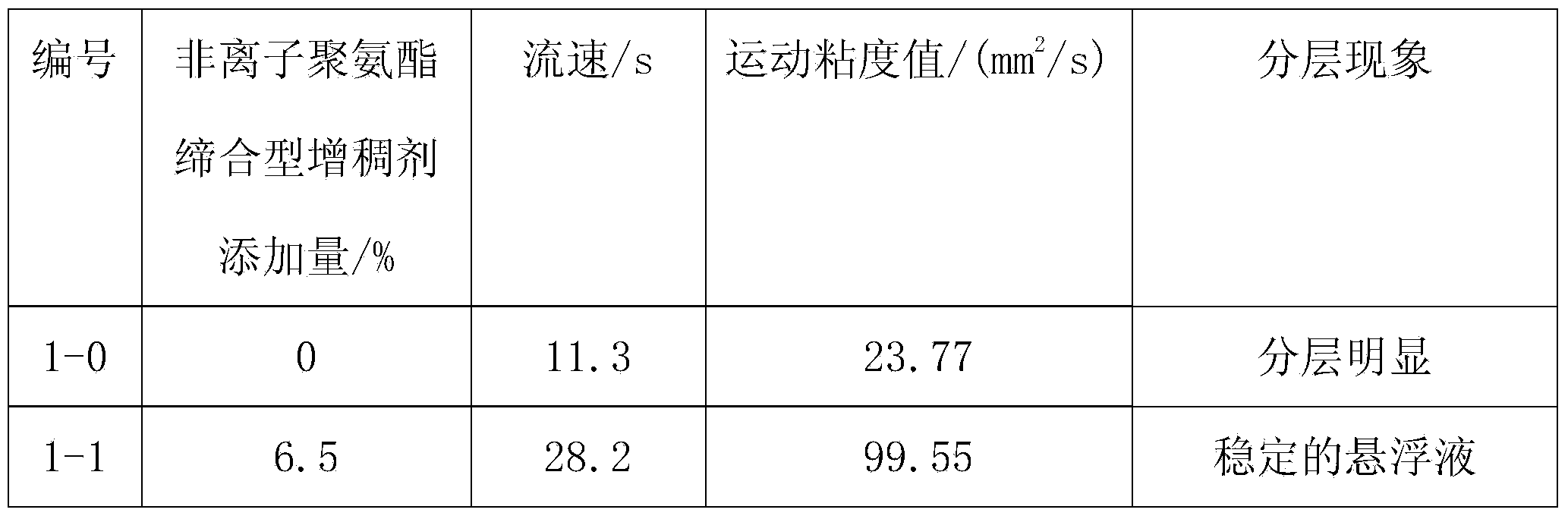

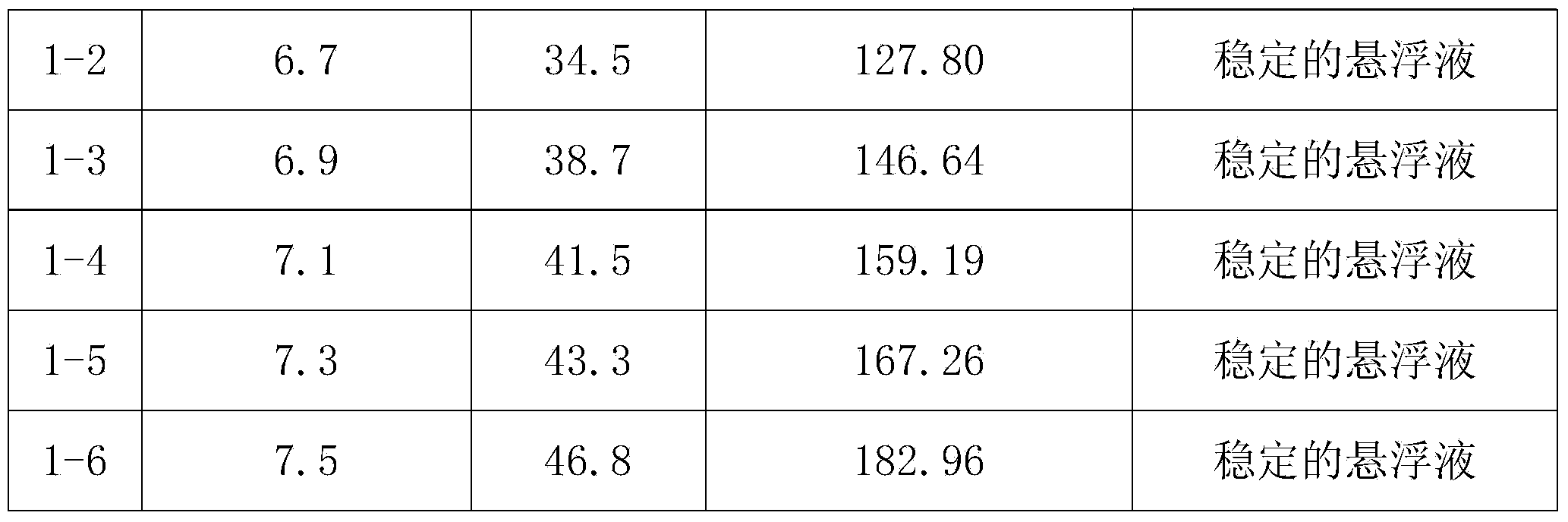

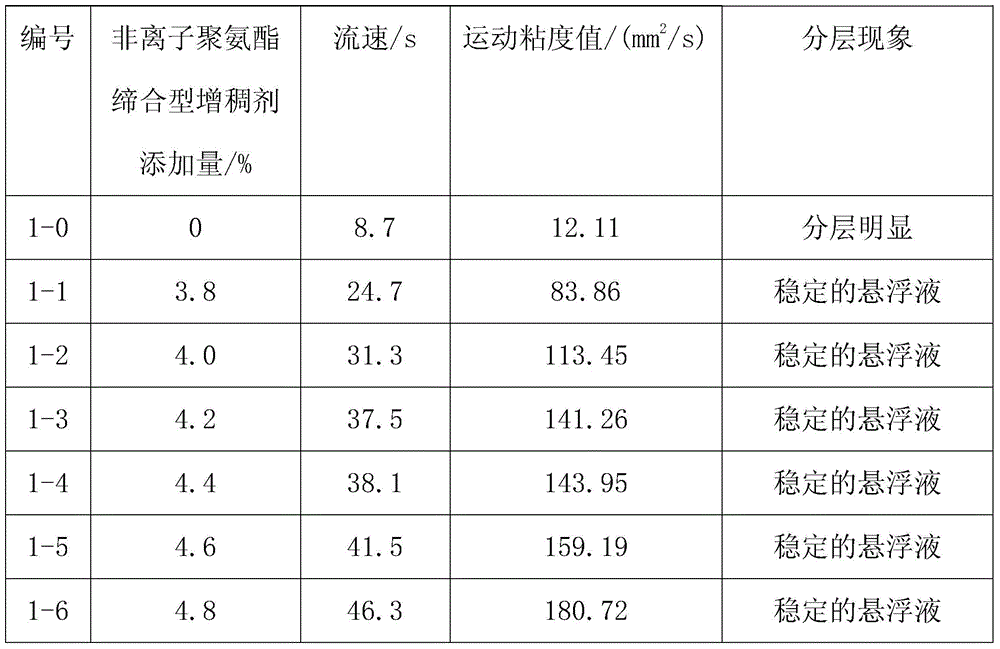

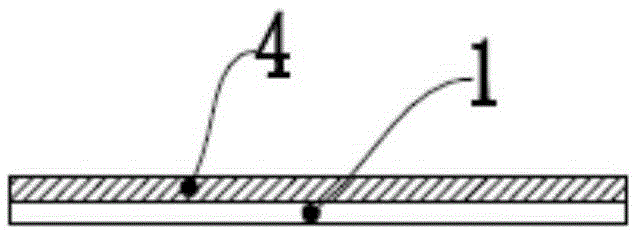

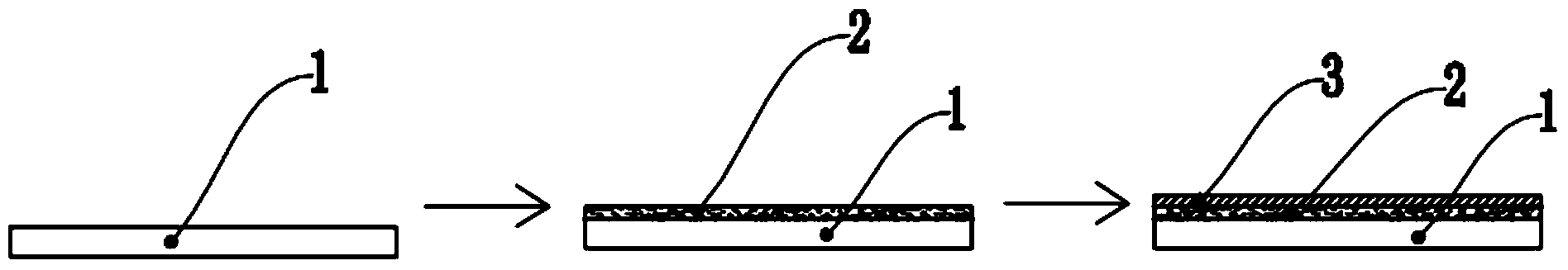

The invention provides a green brick of a single fired glass ceramic composite board. The green brick comprises a green brick body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, wherein a hydrophobic layer is also arranged between the green brick body layer and the ground coat layer; the glass ceramic frit layer is formed by applying a microcrystalline frit particle suspension prepared by mixing glass ceramic frit particles with a frit particle binder to the surface of the ground coat layer; the frit particle binder comprises the following components by mass fraction: 6.5-7.5% of nonionic polyurethane associative thickening agents, 3.2-4.4% of white carbon black, 1-1.5% of defoaming agent, 0.3-1.3% of dispersing agents and the balance of solvents. By using the green brick, the glass ceramic frit particles on the surface can not be drawn away by a draught fan in a preheating zone during firing, thus avoiding waste and reducing the defect rate of the glass ceramic composite board product.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

Green brick of single-firing glass ceramic composite board

ActiveCN104230395ASolve the problem of being easily sucked awayColor effects do not existCelluloseBrick

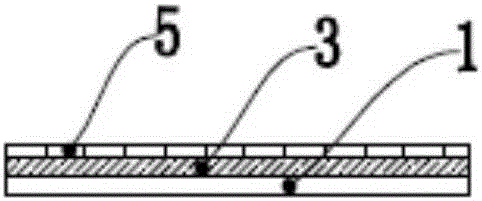

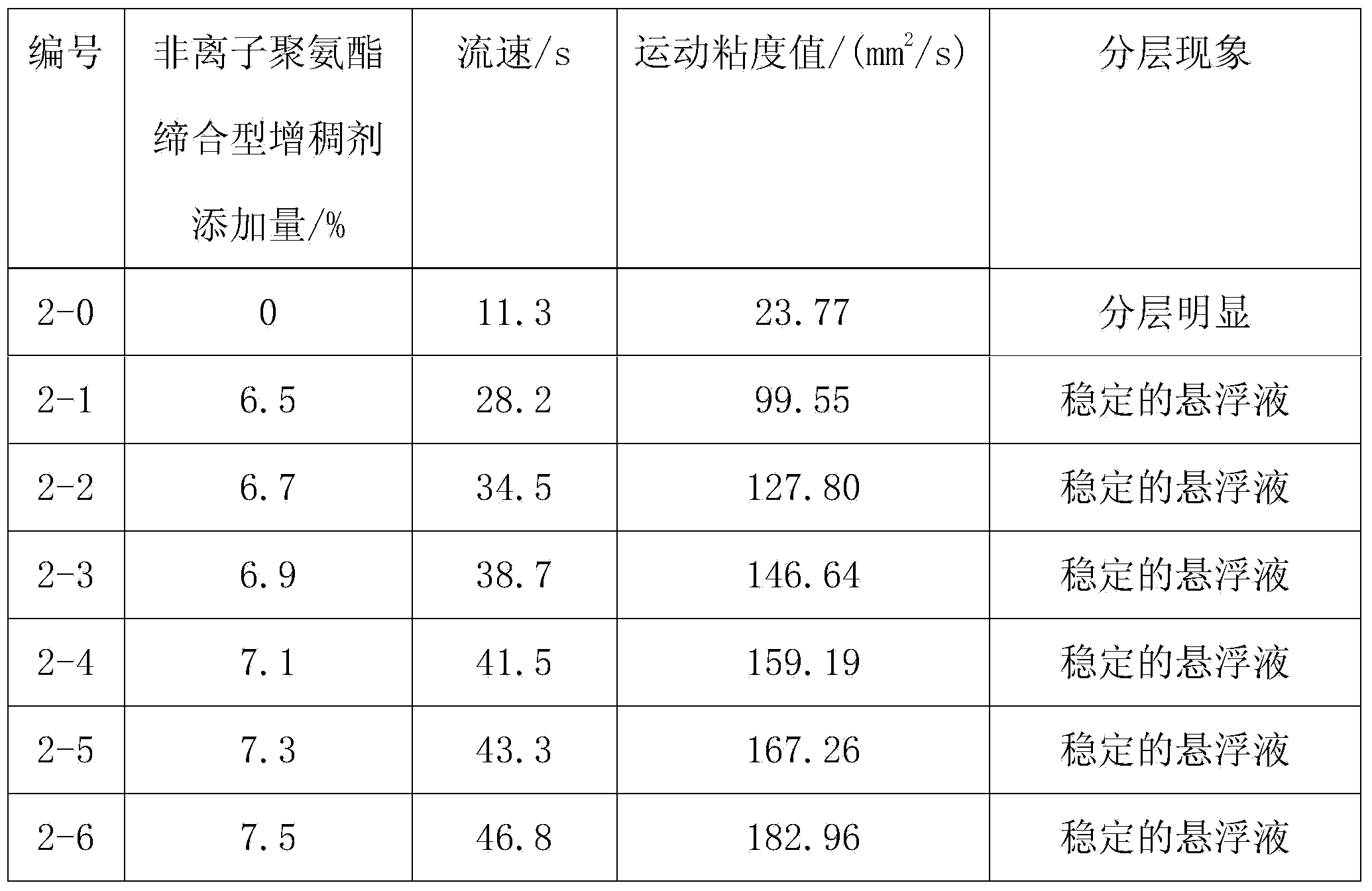

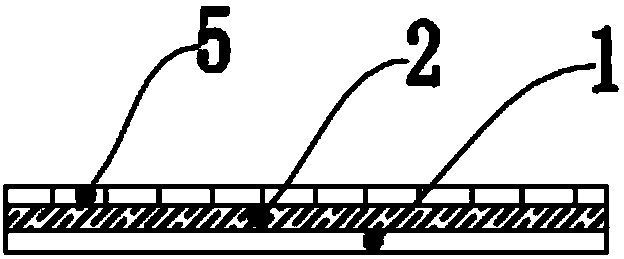

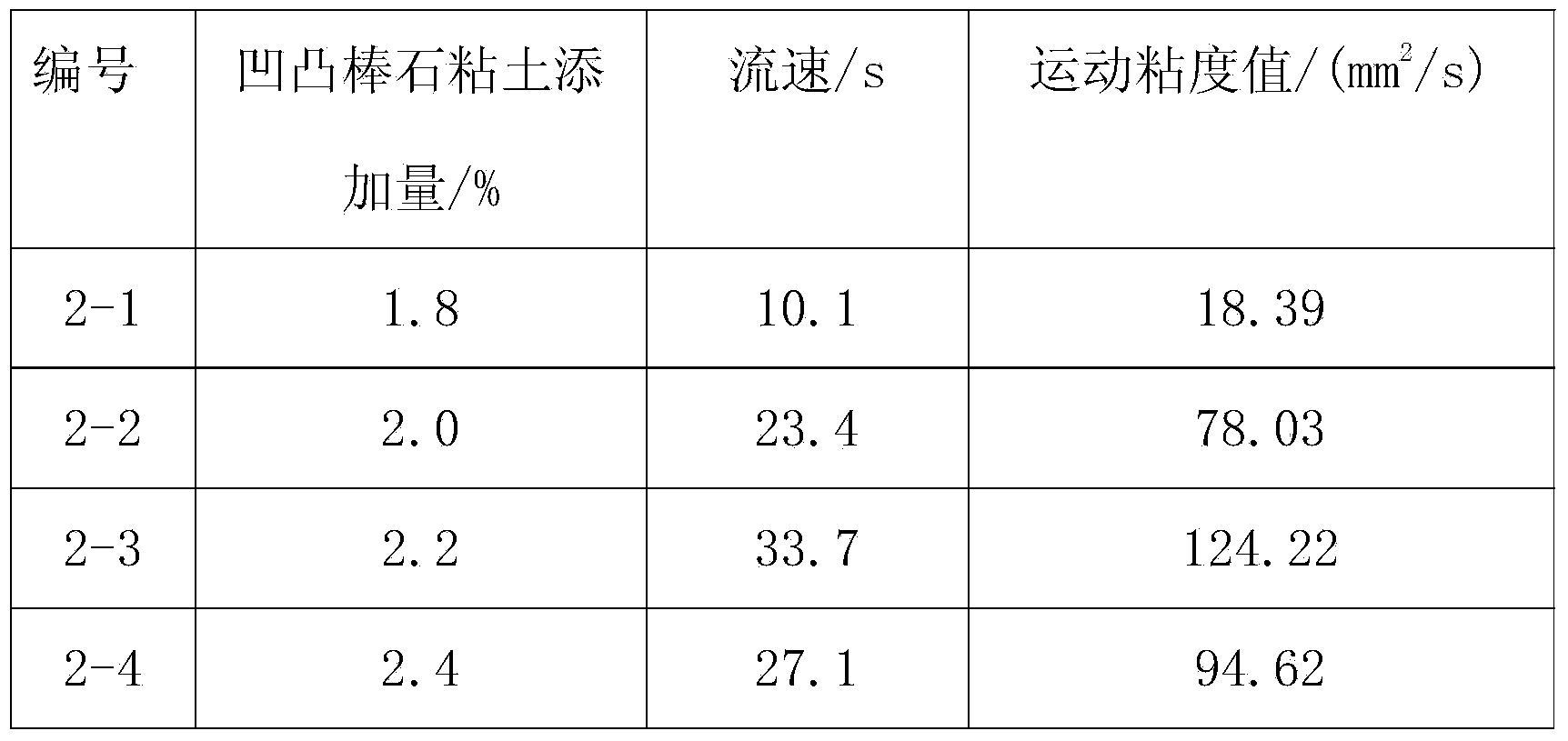

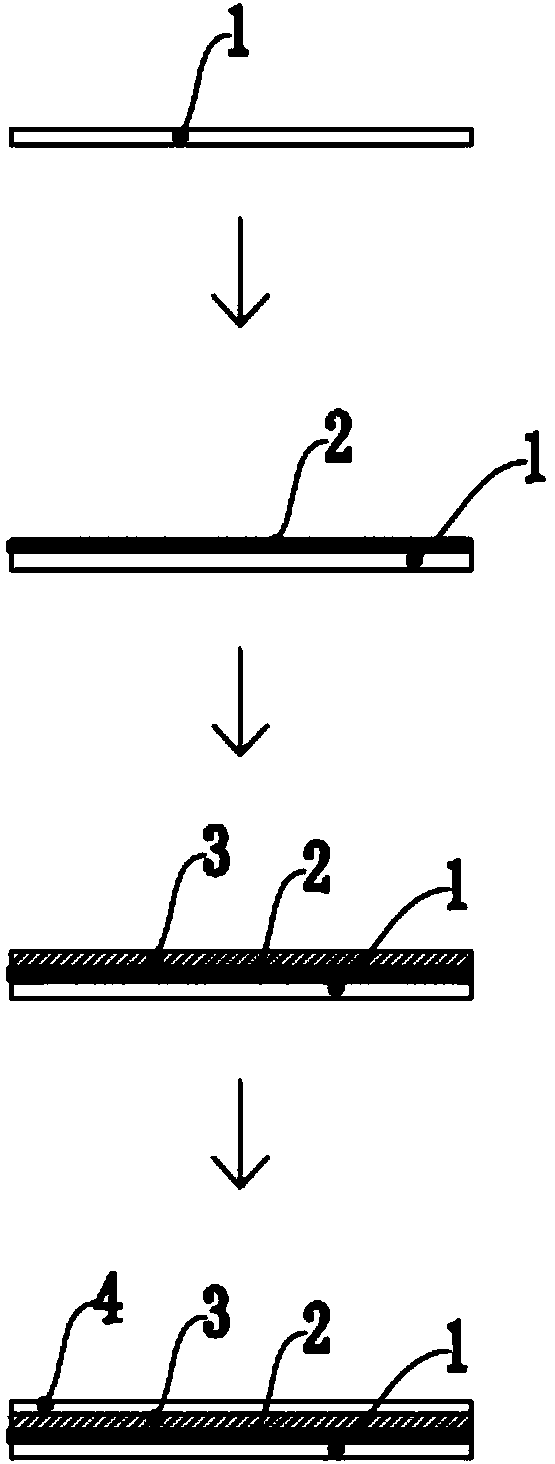

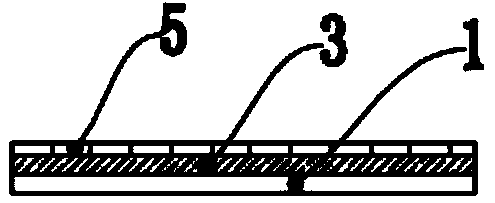

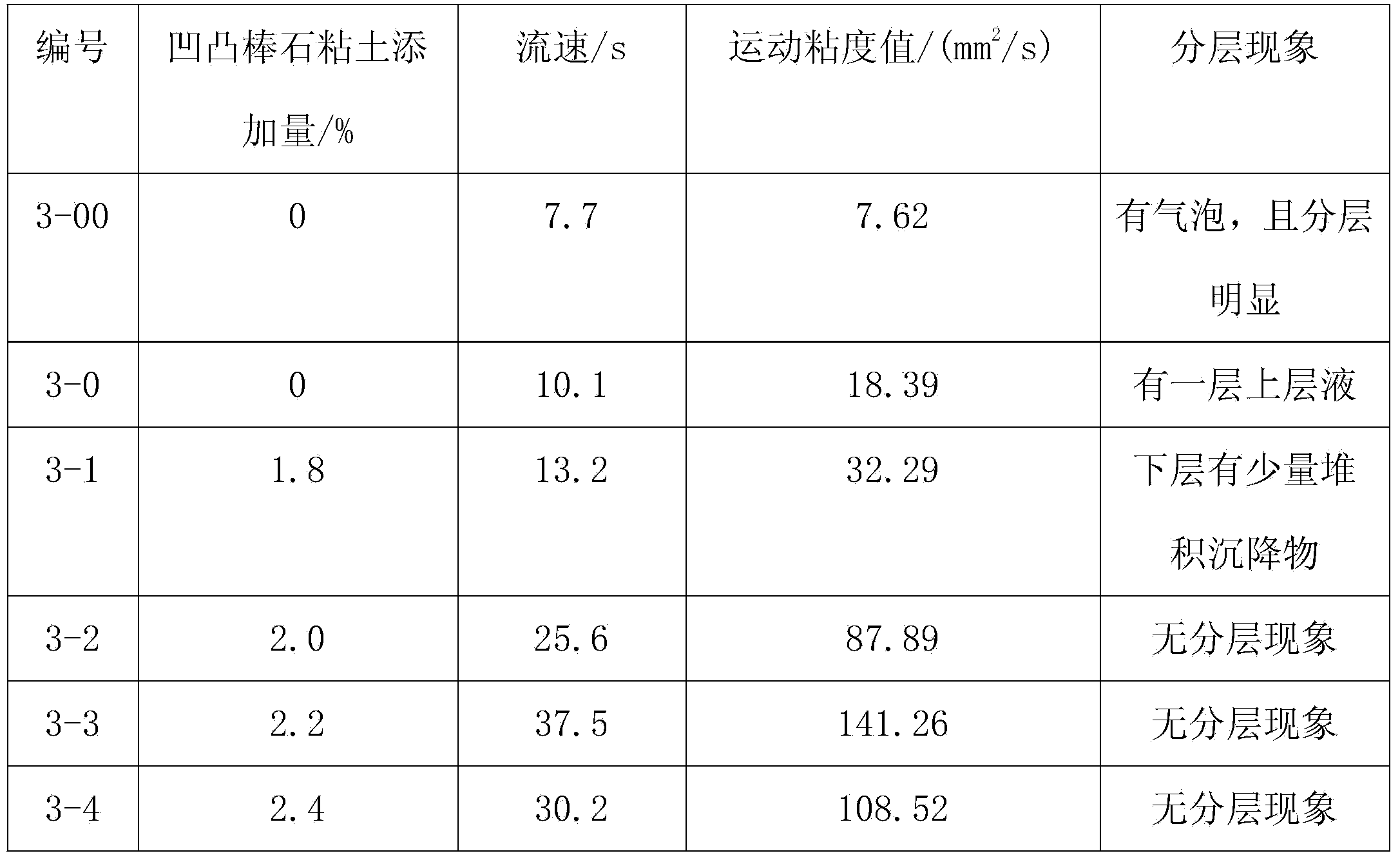

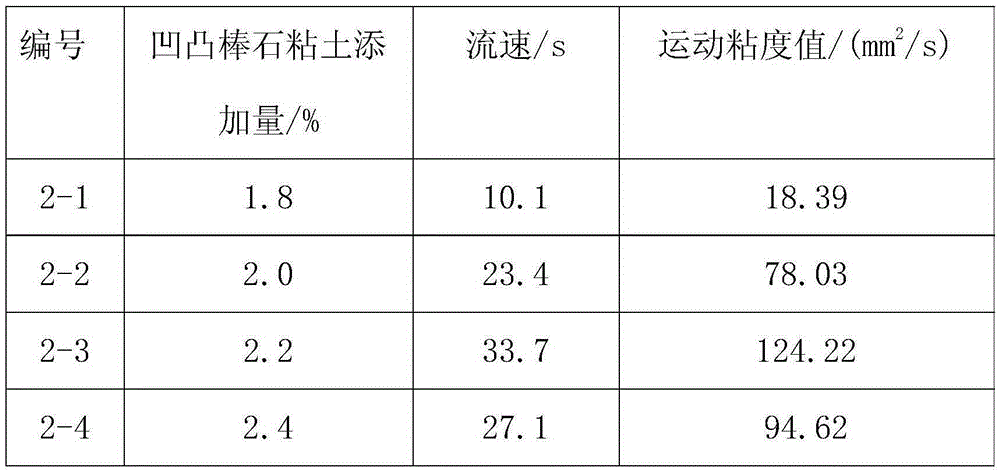

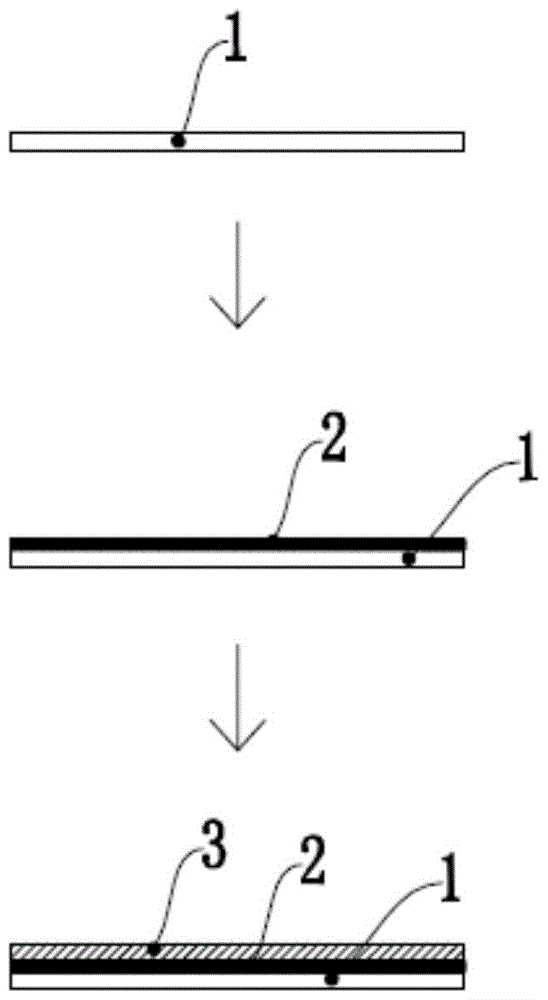

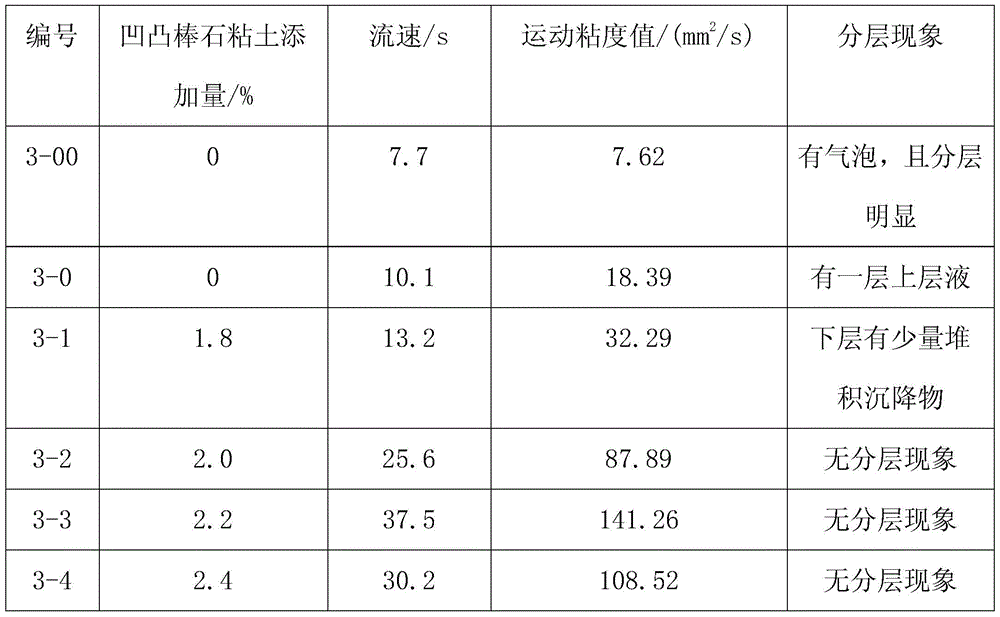

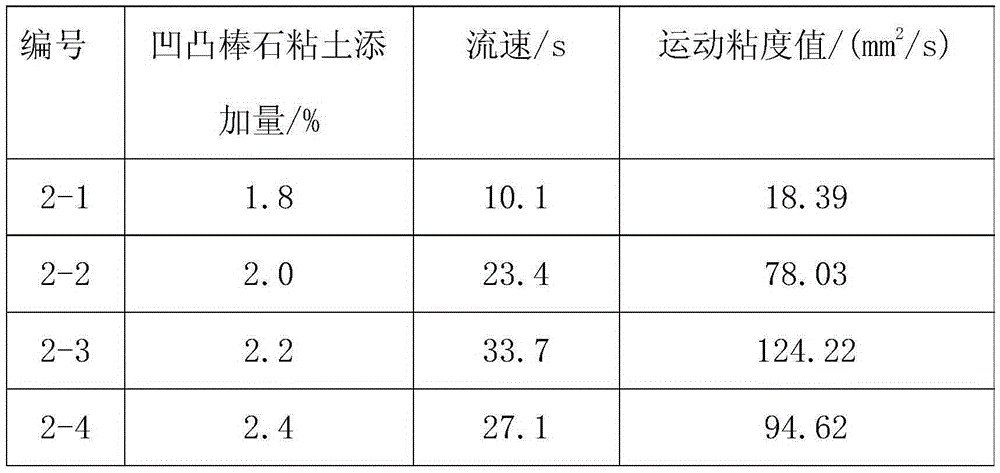

The invention relates to a green brick of a single-firing glass ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, wherein a hydrophobic layer is further arranged between the green body layer and the ground coat layer, the glass ceramic frit layer is formed in a manner that a glass ceramic frit particle suspension liquid formed by blending a glass ceramic frit particle and a frit particle binder is painted on the surface of the ground coat layer, the frit particle binder comprises the following components of in percentage by weight: 5.0-6.0% of a cellulose thickener, 2.0-2.8% of attapulgite, 1.1-1.4% of a defoamer, 1.2-1.8% of a dispersing agent and the balance of a solvent. When the green brick is used, the glass ceramic frit particle on the surface cannot be taken away by an air draught in a preheating zone in the firing, so that the waste is avoided, and the defect rate of a product of the glass ceramic composite board is reduced.

Owner:张家港和智珅知识产权有限公司

Green brick of monofired glass ceramic composite plate

ActiveCN104250111ASolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

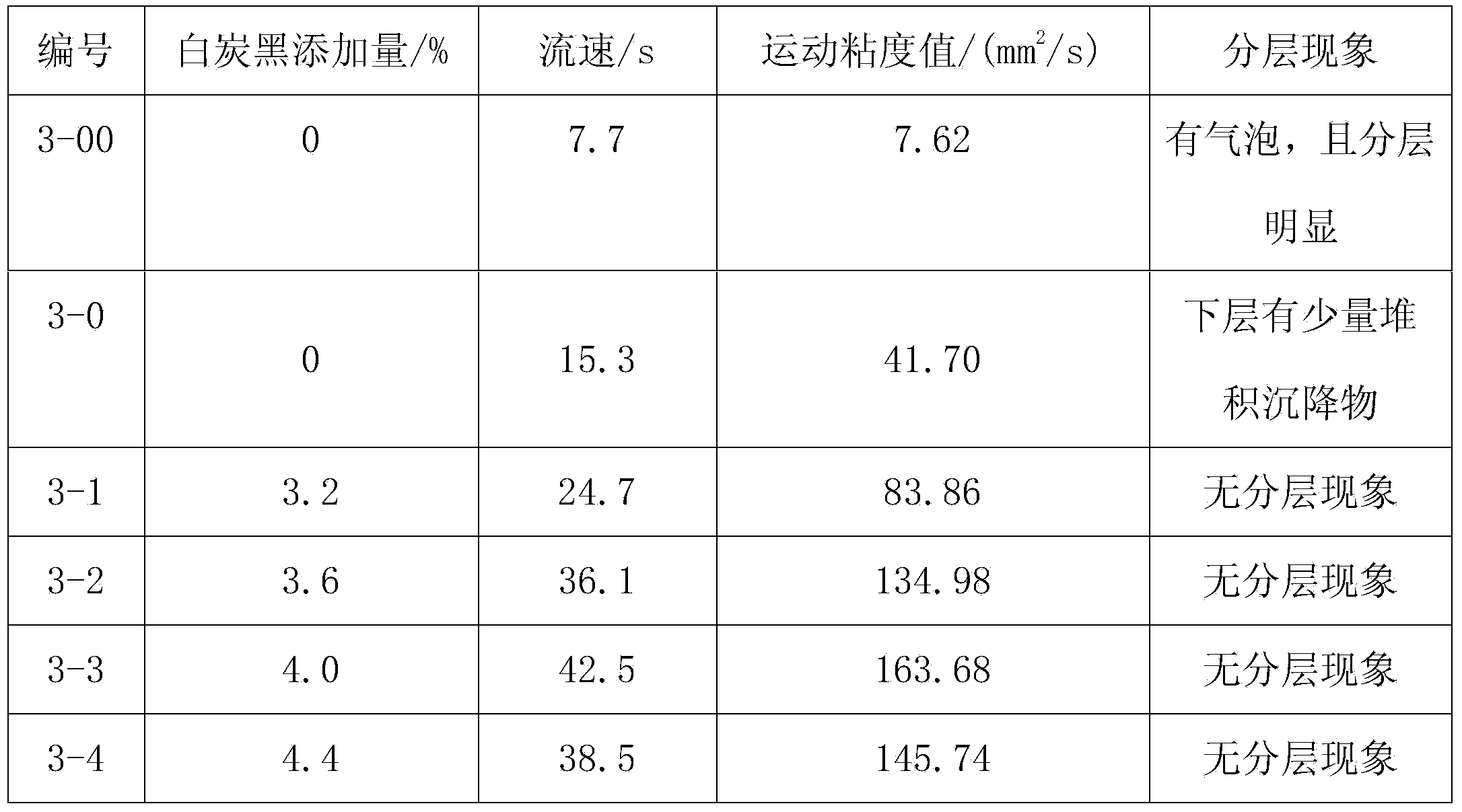

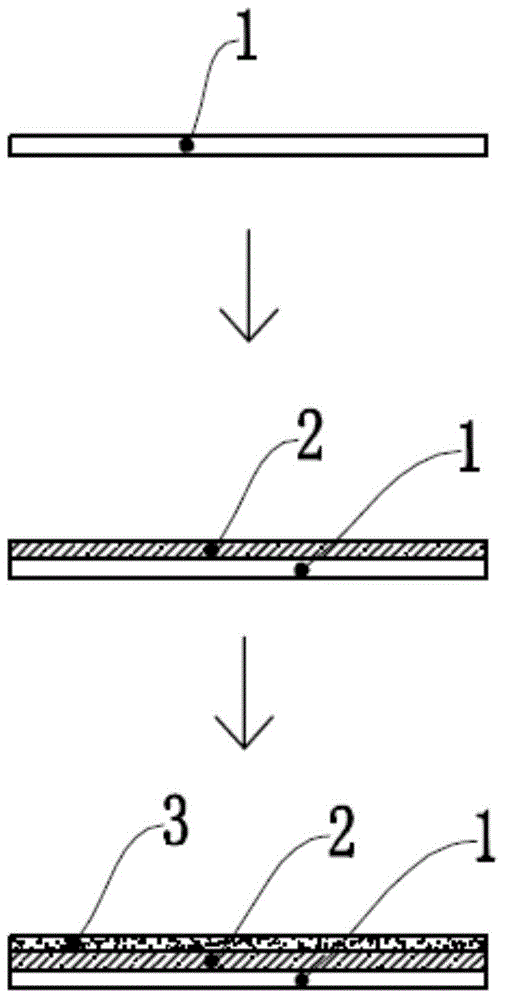

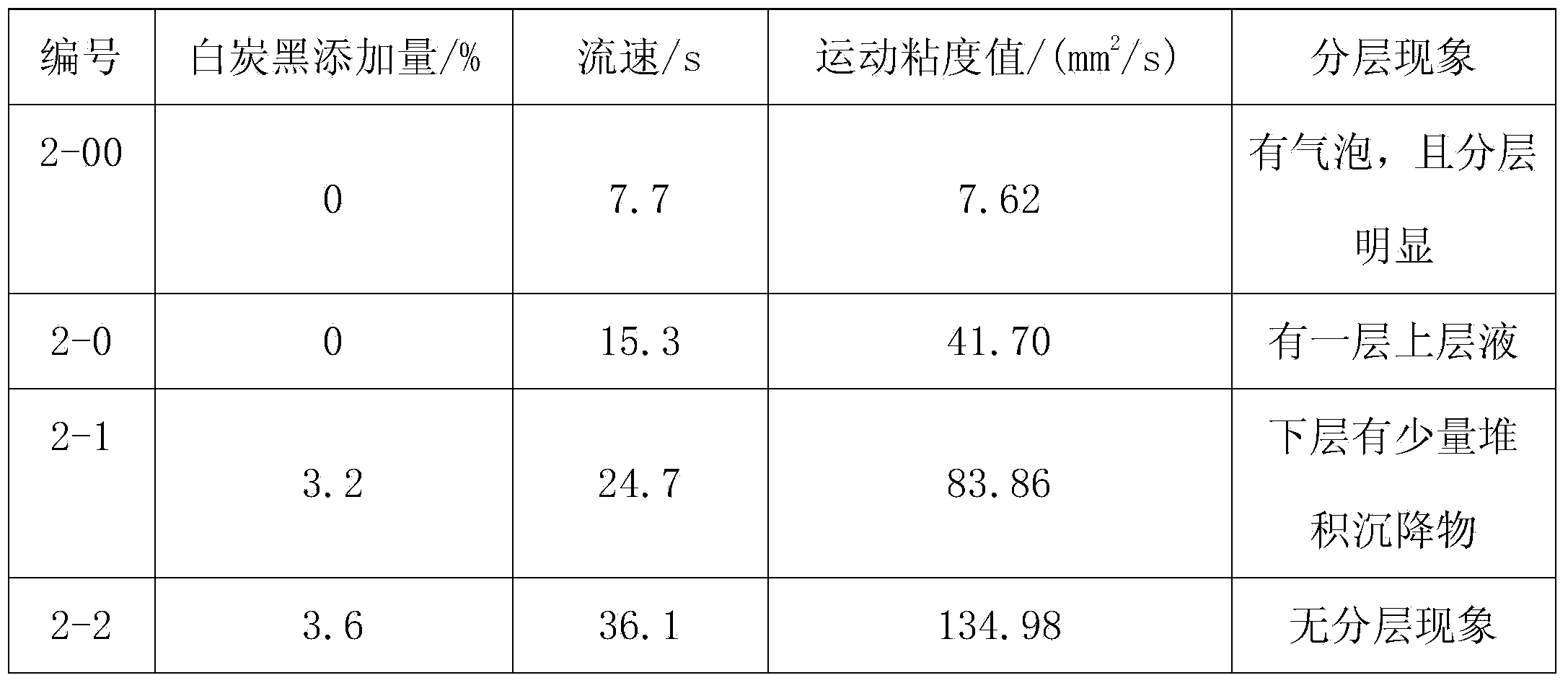

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick comprises a green body layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed in the way that a glass ceramic frit particle suspension liquid formed by mixing glass ceramic frit particles and a frit particle adhesive is applied to the surface of the green body layer; the frit particle adhesive comprises the following components by mass percent: 6.5-7.5 percent of a nonionic polyurethane associative thickener, 3.2-4.4 percent of silica, 1-1.5 percent of a defoamer, 0.3-1.3 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:张家港和智珅知识产权有限公司

A brick structure that burns into microcrystalline glass composite plates at a time

ActiveCN104291878BSolve the problem of being easily sucked awayColor effects do not existGlass compositesBrick

The invention provides a green brick structure of a single fired glass ceramic composite board. The green brick structure comprises a green brick body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, wherein a hydrophobic layer is also arranged between the green brick body layer and the ground coat layer; the glass ceramic frit layer is formed by applying microcrystalline frit particle suspension prepared by mixing glass ceramic frit particles with a frit particle binder to the surface of the ground coat layer; the frit particle binder comprises the following components by mass fraction: 5.5-6.5% of cellulosic thickening agents, 2.5-3.2% of white carbon black, 1.1-1.4% of defoaming agent, 1.2-1.8% of dispersing agents and the balance of solvents. By using the green brick, the glass ceramic frit particles on the surface can not be drawn away by a draught fan in a preheating zone during firing, thus avoiding waste and reducing the defect rate of glass ceramic composite board products.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

A kind of adobe fired into a glass-ceramic composite board at one time

ActiveCN104250116BSolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick comprises a green body layer, a ground glaze layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed in the way that microlite frit particle suspension liquid formed by mixing the glass ceramic frit particles and a frit particle adhesive is applied to the surface of the ground glaze layer; the frit particle adhesive comprises the following components by mass percent: 6.5-7.5 percent of a nonionic polyurethane associative thickener, 3.2-4.4 percent of silica, 1-1.5 percent of a defoamer, 0.3-1.3 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:张家港和智珅知识产权有限公司

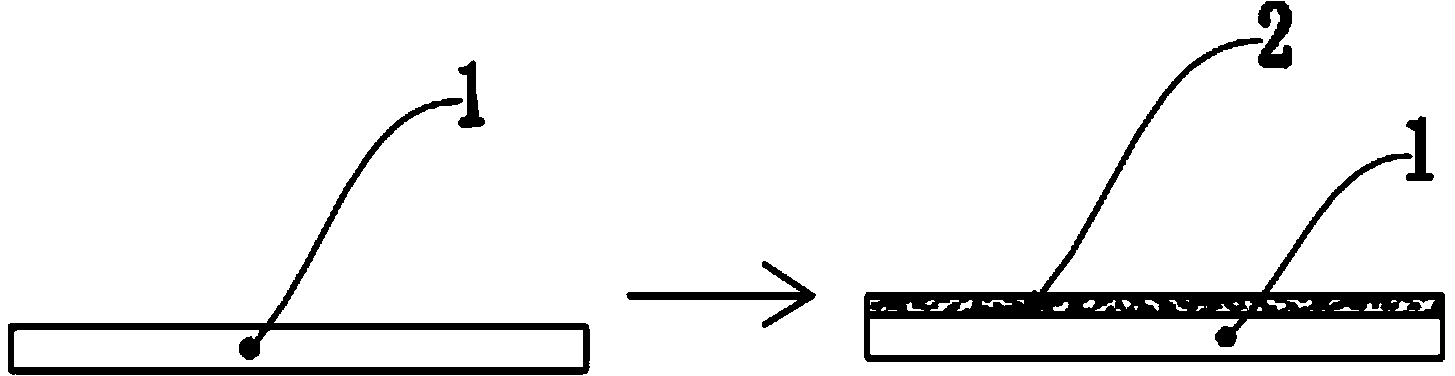

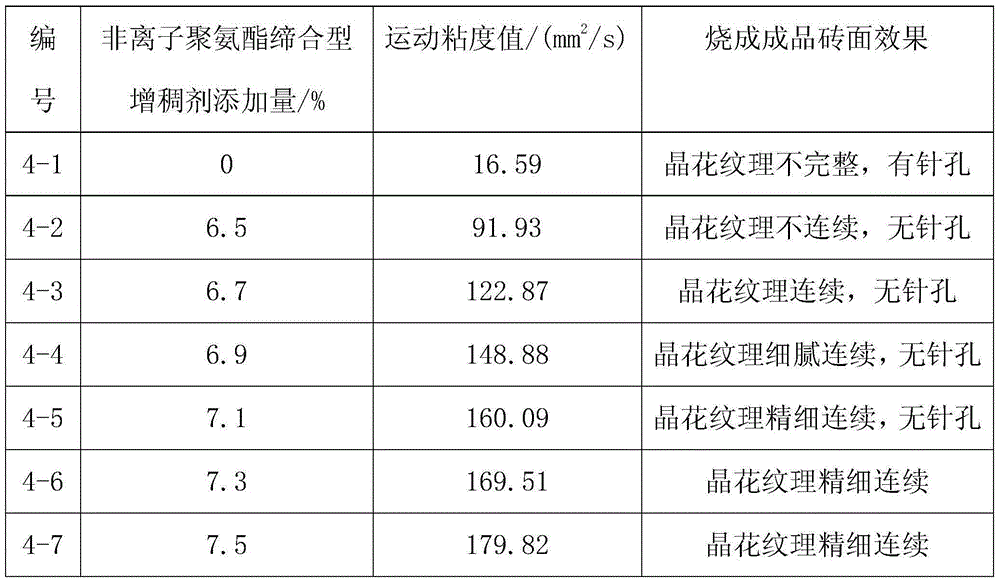

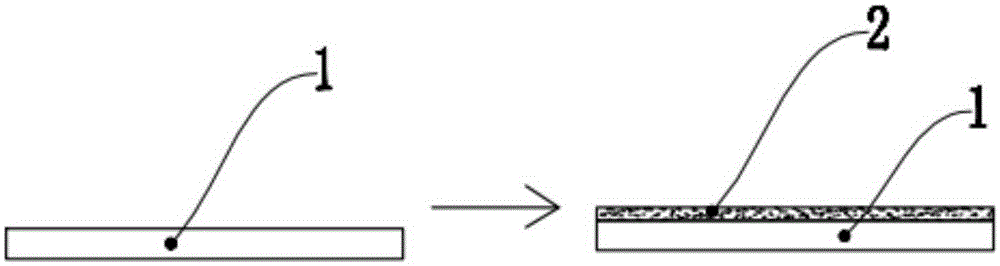

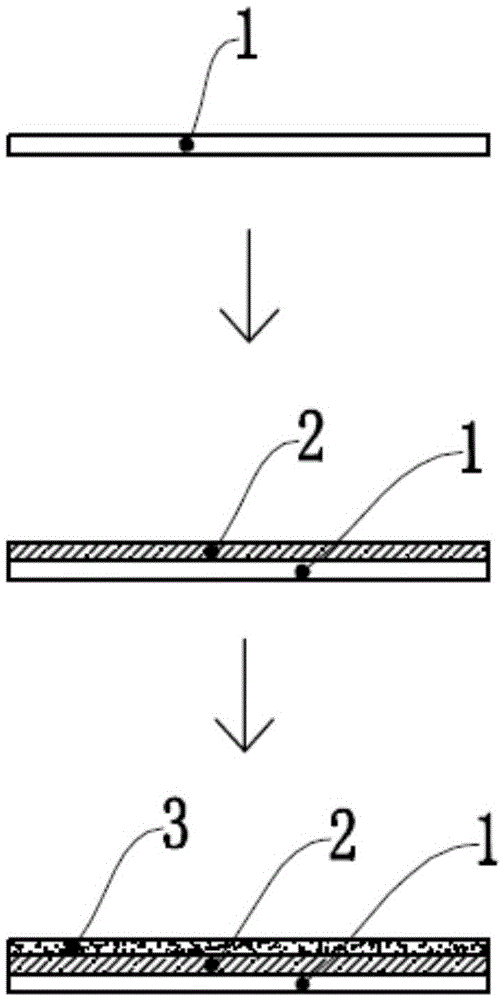

A kind of frit particle binder and preparation method thereof

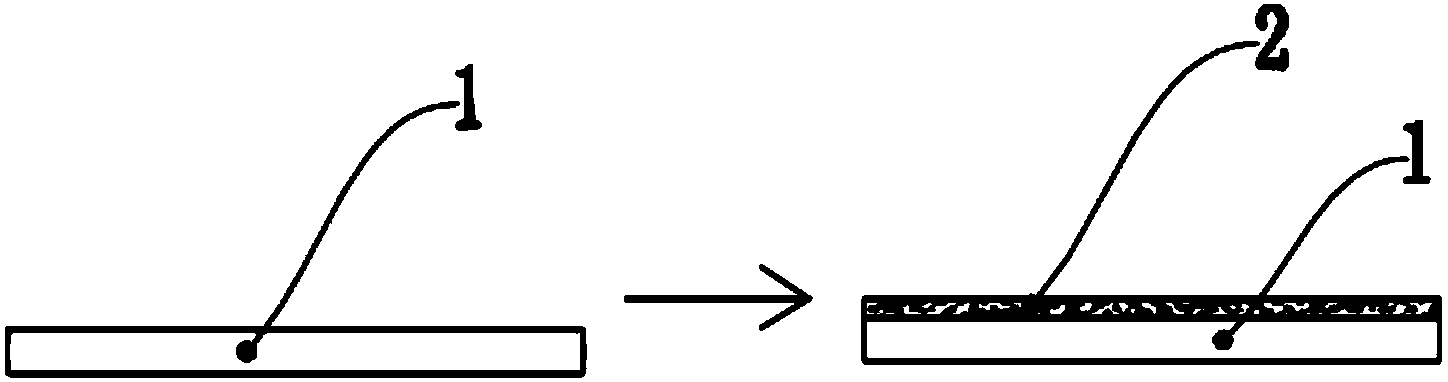

ActiveCN104291684BSolve the problem of being easily sucked awayColor effects do not existFritSolvent

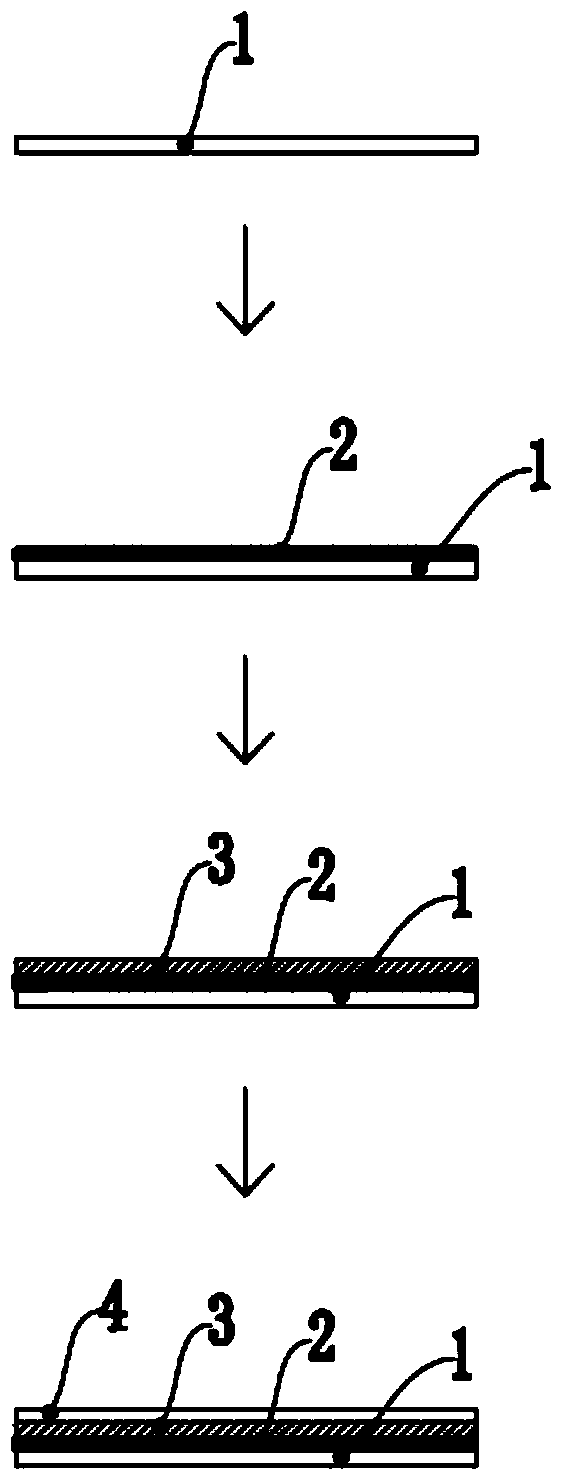

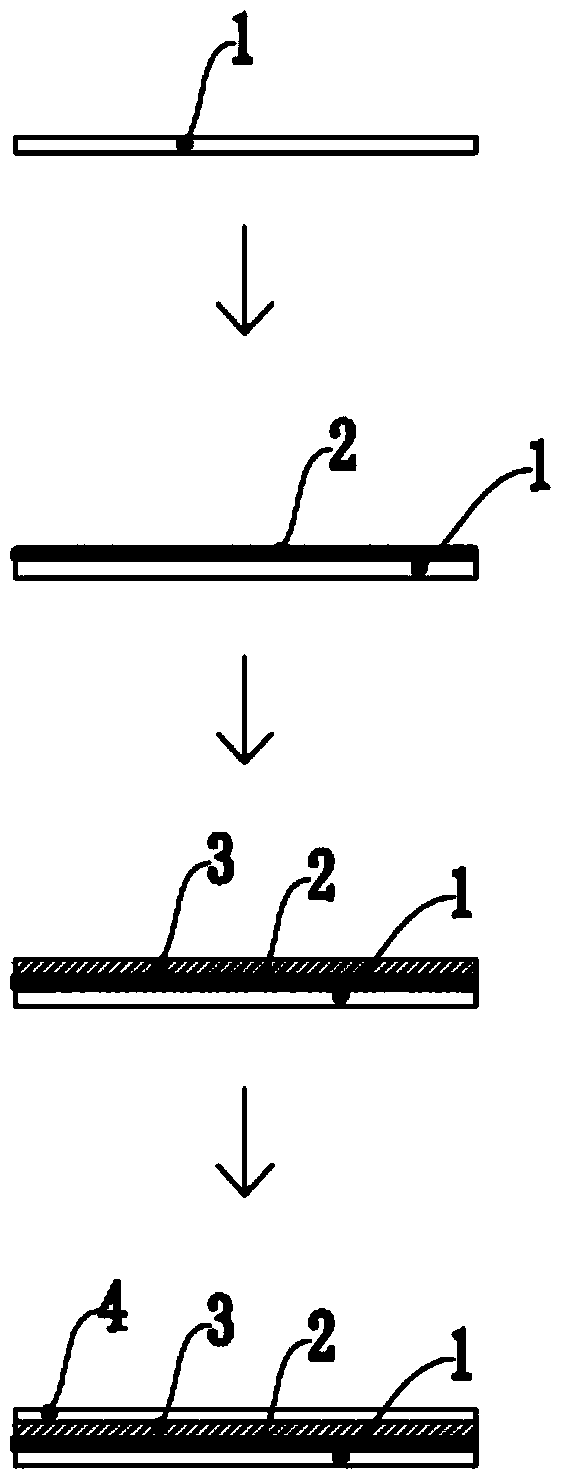

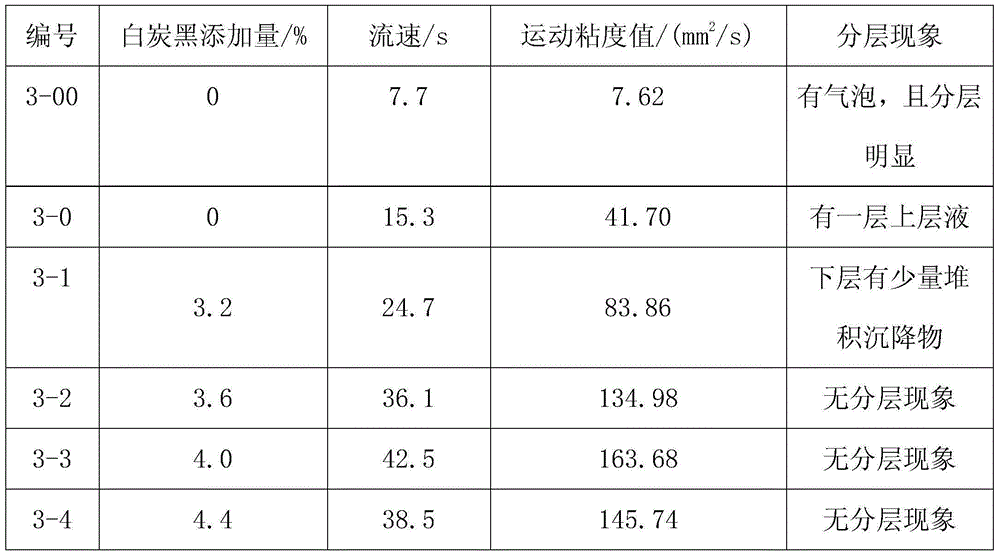

The invention provides a frit particle binder and a preparation method thereof. The frit particle binder comprises the following components by mass fraction: 6.5-7.5% of nonionic polyurethane associative thickening agent, 3.2-4.4% of white carbon black, 1-1.5% of defoaming agent, 0.3-1.3% of dispersing agents and the balance of solvents. A using method of the frit particle binder comprises the steps of uniformly mixing frit particles with the frit particle binder and applying the mixture to the surface of a green body. The other using method of the frit particle binder comprises the steps of firstly laying the frit particles on the surface of the green body according to a designed pattern and then spraying or glazing a layer of frit particle binder on the surfaces of frit particles. By adopting the frit particle binder provided by the invention, the problem that the frit particles face a preheating zone at low negative pressure and are easy to suck away when entering a kiln to be fired is solved. The preparation method of the frit particle binder is simple in production equipment and process.

Owner:江苏鑫宝门窗制造有限公司

A kind of brick blank for one-time firing of glass-ceramic composite plate

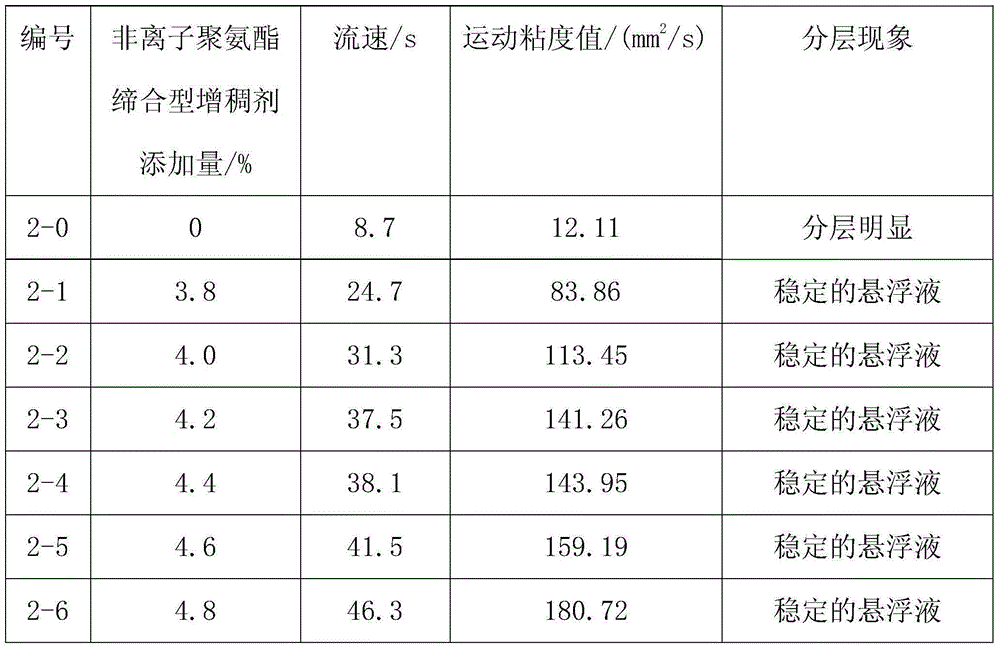

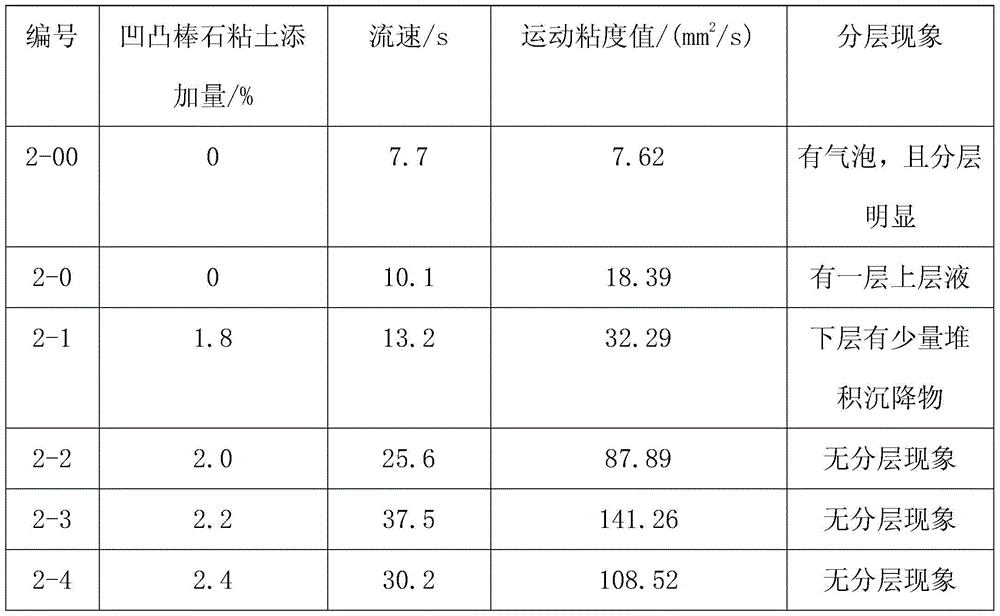

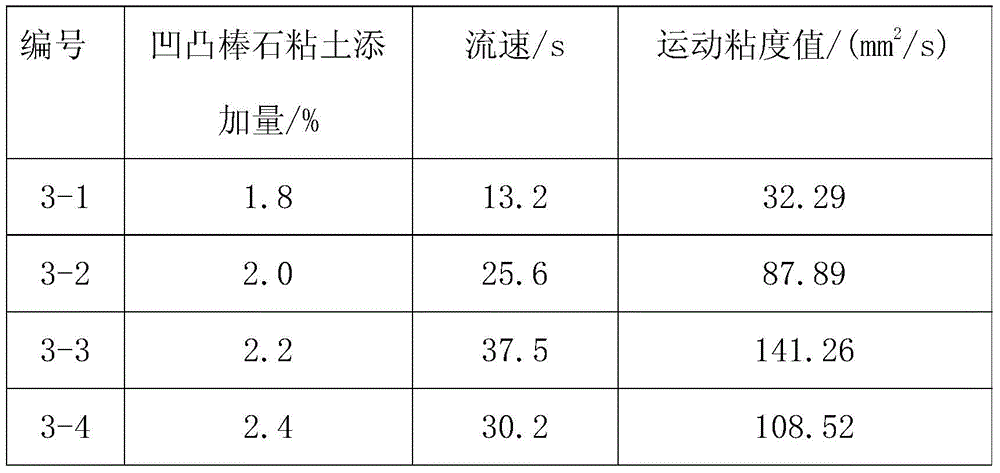

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass-ceramic frit layer from bottom to top, wherein a hydrophobic layer is also arranged between the green body layer and the ground coat layer; the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the ground coat layer; and the frit particle binding agent comprises the following components in percentage by mass: 3.8-4.8% of nonionic polyurethane associative thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of defoaming agent, 0.6-1.6% of dispersing agent and the balance of solvent. By using the green brick, the glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

ActiveCN104250112BSolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

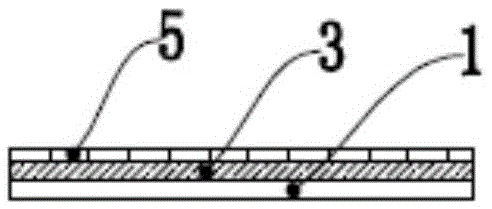

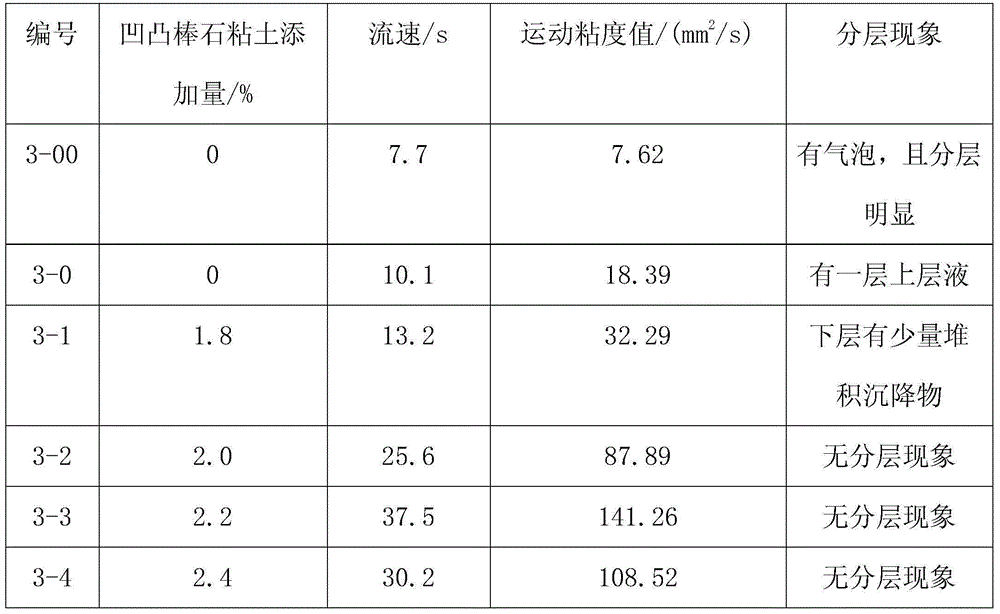

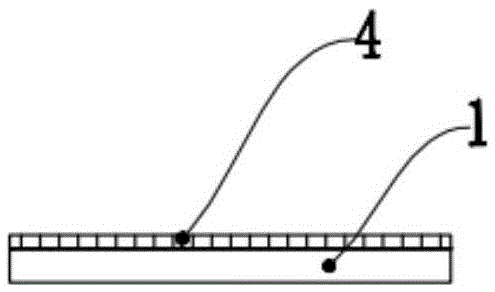

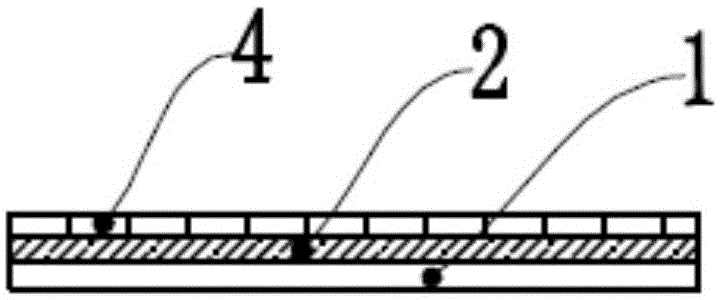

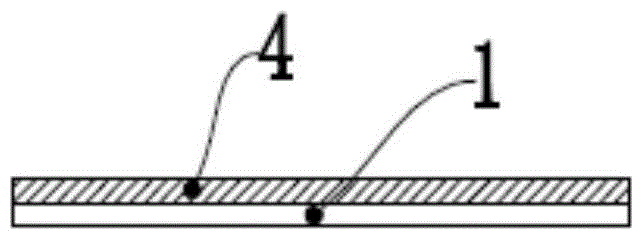

An adobe for firing a glass-ceramics composite board at one time, the adobe includes a green body layer and a glass-ceramics frit layer from bottom to top, and also includes a fixing layer arranged on the surface of the glass-ceramics frit layer; The fixed layer is formed by spraying a glass-ceramic frit particle fixative, and the glass-ceramic frit particle fixative includes the mass fraction of the following components: vitamin thickener 5.0-6.0%, attapulgite 2.0-2.8% %, defoamer 1.1-1.4%, dispersant 1.2-1.8%, and the balance is solvent. Using this kind of adobe, the glass-ceramic frit particles on the surface will not be sucked away by the fan of the preheating zone during firing, thereby avoiding waste and reducing the defect rate of the glass-ceramic composite board product.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

ActiveCN104250114BSolve the problem of being easily sucked awayColor effects do not existBrickPyrophyllite

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick structure comprises a green body layer, a ground glaze layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed in the way that microlite frit particle suspension liquid formed by mixing the glass ceramic frit particles and a frit particle adhesive is applied to the surface of the ground glaze layer; the ground glaze layer comprises 3-5 mass percent of pyrophyllite, and the frit particle adhesive comprises the following components by mass percent: 3.8-4.8 percent of a nonionic polyurethane associative thickener, 1.8-2.4 percent of attapulgite clay, 0.6-1 percent of a defoamer, 0.6-1.6 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:张家港和智珅知识产权有限公司

Green brick of monofired glass ceramic composite plate

ActiveCN104250116ASolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick comprises a green body layer, a ground glaze layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed in the way that microlite frit particle suspension liquid formed by mixing the glass ceramic frit particles and a frit particle adhesive is applied to the surface of the ground glaze layer; the frit particle adhesive comprises the following components by mass percent: 6.5-7.5 percent of a nonionic polyurethane associative thickener, 3.2-4.4 percent of silica, 1-1.5 percent of a defoamer, 0.3-1.3 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:张家港和智珅知识产权有限公司

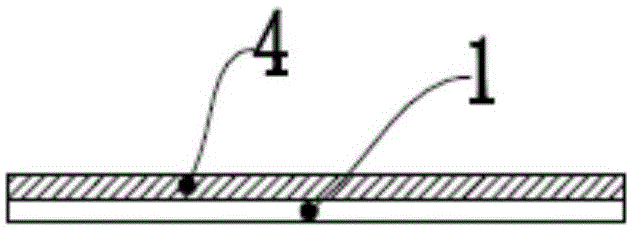

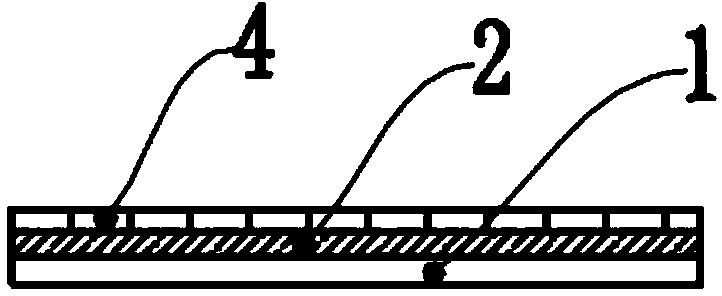

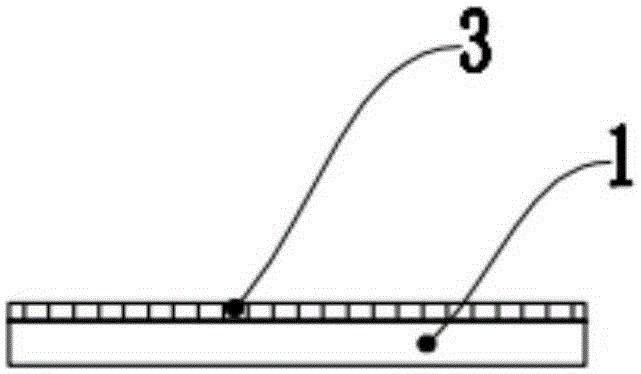

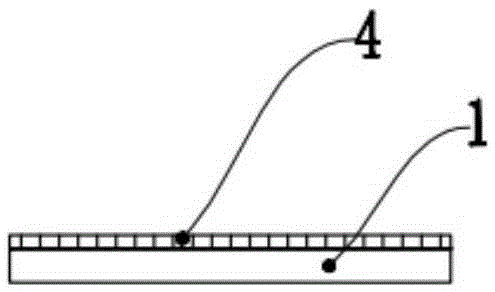

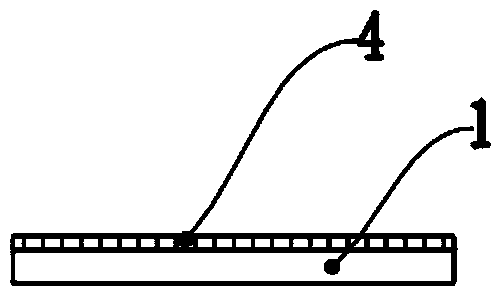

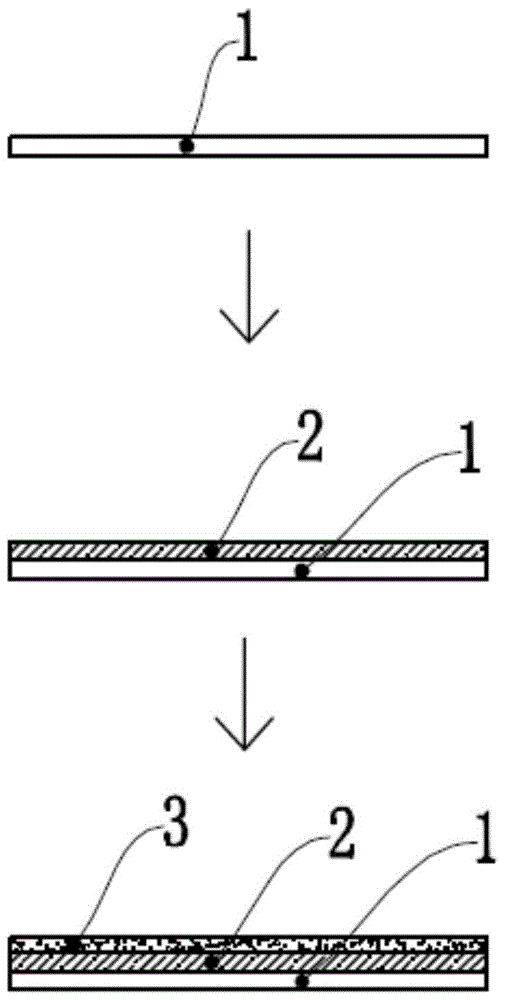

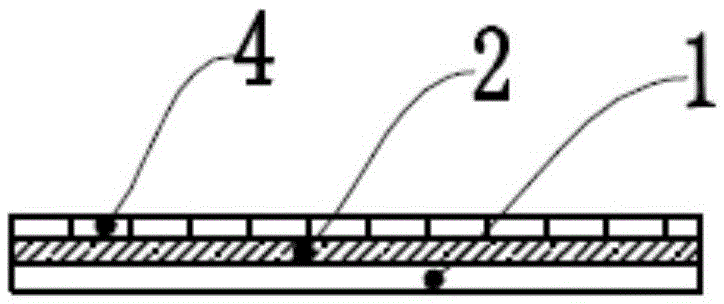

A brick adobe fired into a glass-ceramic composite board at one time

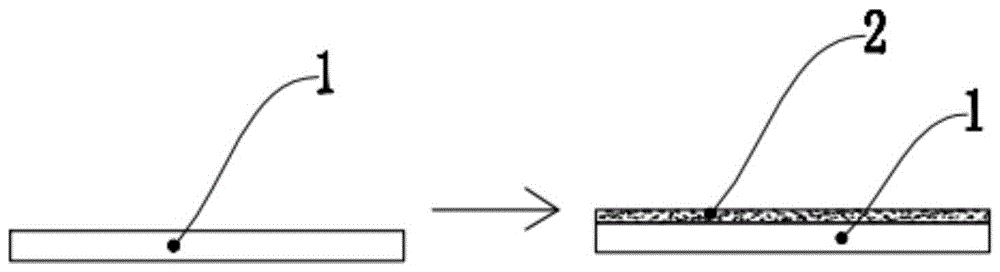

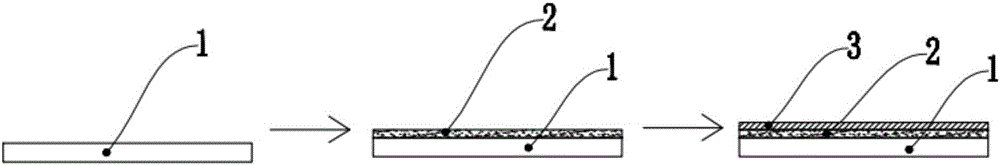

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass-ceramic frit layer from bottom to top and also comprises a fixing layer arranged on the surface of the glass-ceramic frit layer, wherein the fixing layer is formed by spraying a glass-ceramic frit particle fixing agent; and the glass-ceramic frit particle fixing agent comprises the following components in percentage by mass: 6.5-7.5% of nonionic polyurethane associative thickener, 3.2-4.4% of white carbon black, 1-1.5% of defoaming agent, 0.3-1.3% of dispersing agent and the balance of solvent. By using the green brick, glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:靖江市红星铜业制造有限公司

Green brick of single-firing glass ceramic composite board

ActiveCN104230393ASolve the problem of being easily sucked awayColor effects do not existBrickPyrophyllite

The invention relates to a green brick of a single-firing glass ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, and further comprises a fixing layer arranged on the surface of the glass ceramic fruit layer, wherein the fixing layer is formed by spraying a glass ceramic frit particle fixing agent, the ground coat layer contains 3%-5% of pyrophyllite according to mass percent, and the glass ceramic frit particle fixing agent comprises the following components in percentage by weight: 3.8-4.8% of a nonionic polyurethane associated thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of a defoamer, 0.6-1.6% of a dispersing agent and the balance of a solvent. When the green brick is used, a glass ceramic frit particle on the surface cannot be taken away by an air draught in a preheating zone in the firing, so that the waste is avoided, and the defect rate of a product of the glass ceramic composite board is reduced.

Owner:张家港和智珅知识产权有限公司

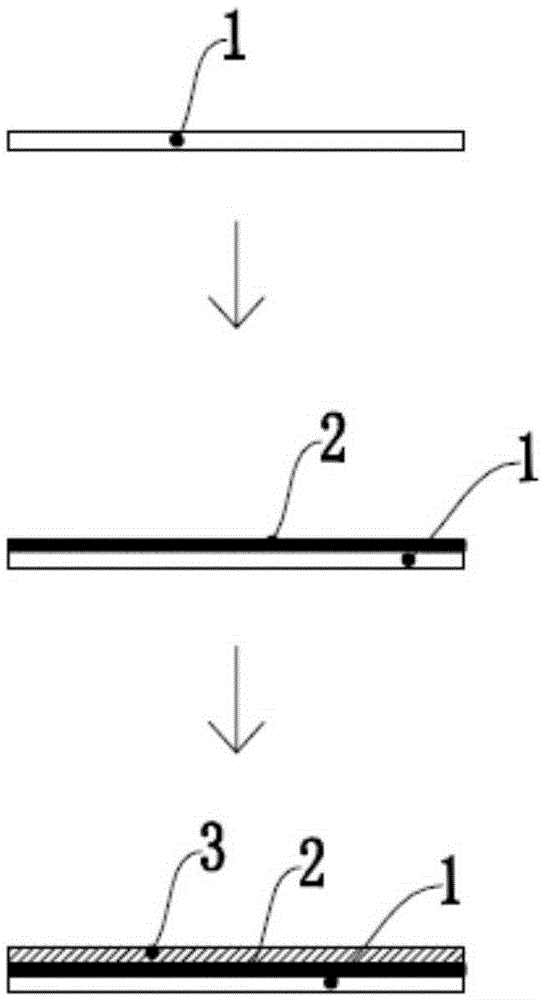

Green brick of one-step sintered glass-ceramic composite board

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass-ceramic frit layer from bottom to top, wherein a hydrophobic layer is also arranged between the green body layer and the ground coat layer; the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the ground coat layer; and the frit particle binding agent comprises the following components in percentage by mass: 3.8-4.8% of nonionic polyurethane associative thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of defoaming agent, 0.6-1.6% of dispersing agent and the balance of solvent. By using the green brick, the glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:张家港和智珅知识产权有限公司

A kind of adobe fired into a glass-ceramic composite board at one time

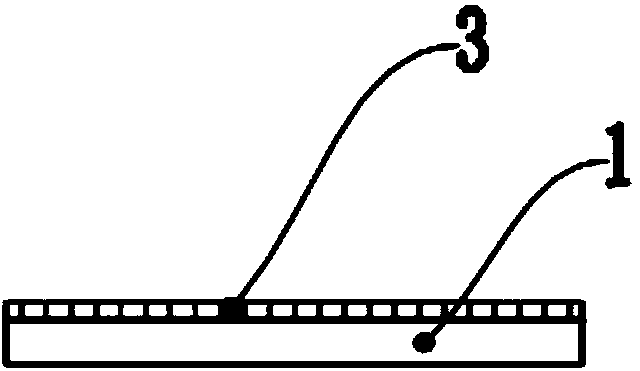

ActiveCN104261681BSolve the problem of being easily sucked awayColor effects do not existCelluloseBrick

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer and a glass-ceramic frit layer from bottom to top, wherein the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the green body layer; and the frit particle binding agent comprises the following components in percentage by mass: 5.5-6.5% of cellulose thickener, 2.5-3.2% of white carbon black, 1.1-1.4% of defoaming agent, 1.2-1.8% of dispersing agent and the balance of solvent. By using the green brick, glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

Owner:江苏鑫宝门窗制造有限公司

A brick adobe fired into a glass-ceramic composite board at one time

ActiveCN104230393BSolve the problem of being easily sucked awayColor effects do not existPyrophylliteBrick

The invention relates to a green brick of a single-firing glass ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, and further comprises a fixing layer arranged on the surface of the glass ceramic fruit layer, wherein the fixing layer is formed by spraying a glass ceramic frit particle fixing agent, the ground coat layer contains 3%-5% of pyrophyllite according to mass percent, and the glass ceramic frit particle fixing agent comprises the following components in percentage by weight: 3.8-4.8% of a nonionic polyurethane associated thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of a defoamer, 0.6-1.6% of a dispersing agent and the balance of a solvent. When the green brick is used, a glass ceramic frit particle on the surface cannot be taken away by an air draught in a preheating zone in the firing, so that the waste is avoided, and the defect rate of a product of the glass ceramic composite board is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

A brick made of a glass-ceramic composite board fired at one time, the brick comprises a body layer, a bottom glaze layer and a glass-ceramic frit layer from bottom to top, and there is a gap between the body layer and the bottom glaze layer A hydrophobic layer is provided, and the glass-ceramic frit layer is formed by applying a suspension of microcrystalline frit particles mixed with frit particles of glass-ceramics and a frit particle binder to the surface of the underglaze layer; The mass fraction of the frit granule binder includes the following components: cellulose thickener 5.0-6.0%, attapulgite 2.0-2.8%, defoamer 1.1-1.4%, dispersant 1.2-1.8%, The balance is solvent. Using this kind of adobe, the glass-ceramic frit particles on the surface will not be sucked away by the fan of the preheating zone during firing, thereby avoiding waste and reducing the defect rate of the glass-ceramic composite board product.

Owner:张家港和智珅知识产权有限公司

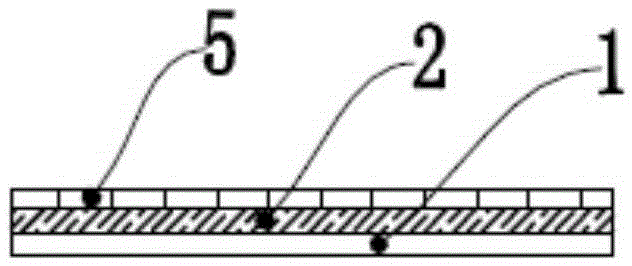

Green brick of one-step sintered glass-ceramic composite board

ActiveCN104261894ASolve the problem of being easily sucked awayColor effects do not existSolventDefoaming Agents

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer, a ground coat layer and a glass-ceramic frit layer from bottom to top and also comprises a fixing layer arranged on the surface of the glass-ceramic frit layer, wherein the fixing layer is formed by spraying a glass-ceramic frit particle fixing agent; and the glass-ceramic frit particle fixing agent comprises the following components in percentage by mass: 6.5-7.5% of nonionic polyurethane associative thickener, 3.2-4.4% of white carbon black, 1-1.5% of defoaming agent, 0.3-1.3% of dispersing agent and the balance of solvent. By using the green brick, glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:靖江市红星铜业制造有限公司

Frit particle binder and preparation method thereof

ActiveCN104291684ASolve the problem of being easily sucked awayColor effects do not existFritSolvent

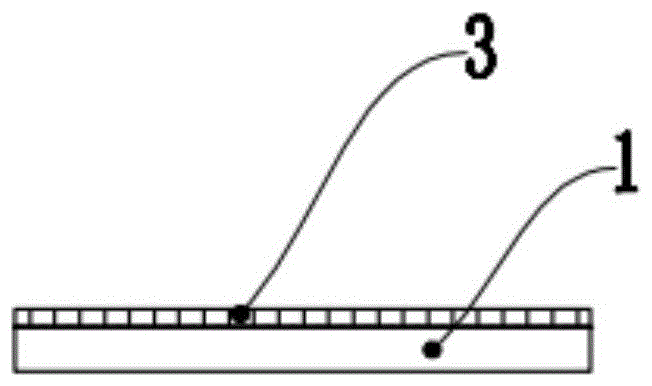

The invention provides a frit particle binder and a preparation method thereof. The frit particle binder comprises the following components by mass fraction: 6.5-7.5% of nonionic polyurethane associative thickening agent, 3.2-4.4% of white carbon black, 1-1.5% of defoaming agent, 0.3-1.3% of dispersing agents and the balance of solvents. A using method of the frit particle binder comprises the steps of uniformly mixing frit particles with the frit particle binder and applying the mixture to the surface of a green body. The other using method of the frit particle binder comprises the steps of firstly laying the frit particles on the surface of the green body according to a designed pattern and then spraying or glazing a layer of frit particle binder on the surfaces of frit particles. By adopting the frit particle binder provided by the invention, the problem that the frit particles face a preheating zone at low negative pressure and are easy to suck away when entering a kiln to be fired is solved. The preparation method of the frit particle binder is simple in production equipment and process.

Owner:江苏鑫宝门窗制造有限公司

A kind of frit particle binder and preparation method thereof

ActiveCN104291683BSolve the problem of being easily sucked awayColor effects do not existFritSolvent

Owner:重庆创新燃料电池技术产业研究院有限公司

A brick adobe fired into a glass-ceramic composite board at one time

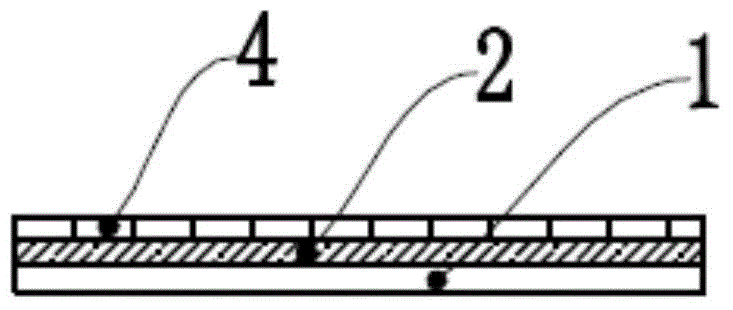

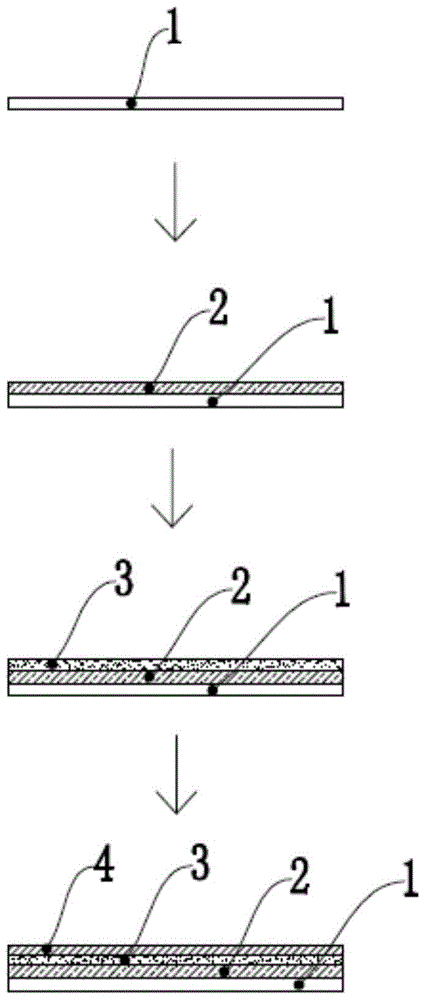

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer and a glass-ceramic frit layer from bottom to top, wherein a hydrophobic layer is also arranged between the green body layer and the glass-ceramic frit layer; the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the hydrophobic layer; and the frit particle binding agent comprises the following components in percentage by mass: 3.8-4.8% of nonionic polyurethane associative thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of defoaming agent, 0.6-1.6% of dispersing agent and the balance of solvent. By using the green brick, the glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced; and a hydrophobic agent is used in the scheme, so that the affect of a fixing agent to the strength of a green body can be avoided.

Owner:广西新高盛薄型建陶有限公司

Green brick of one-step sintered glass-ceramic composite board

ActiveCN104261681ASolve the problem of being easily sucked awayColor effects do not existCelluloseBrick

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer and a glass-ceramic frit layer from bottom to top, wherein the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the green body layer; and the frit particle binding agent comprises the following components in percentage by mass: 5.5-6.5% of cellulose thickener, 2.5-3.2% of white carbon black, 1.1-1.4% of defoaming agent, 1.2-1.8% of dispersing agent and the balance of solvent. By using the green brick, glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:张家港和智珅知识产权有限公司

A kind of brick blank for one-time firing of glass-ceramic composite plate

The invention discloses a green brick of a one-step sintered glass-ceramic composite board. The green brick comprises a green body layer and a glass-ceramic frit layer from bottom to top, wherein the glass-ceramic frit layer is formed by applying a glass-ceramic frit particle suspension liquid formed by mixing glass-ceramic frit particles and a frit particle binding agent on the surface of the green body layer; and the frit particle binding agent comprises the following components in percentage by mass: 3.8-4.8% of nonionic polyurethane associative thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of defoaming agent, 0.6-1.6% of dispersing agent and the balance of solvent. By using the green brick, the glass-ceramic frit particles on the surface cannot be taken away by a draught fan at a preheating zone when being sintered, so that the waste is avoided, and the defect rate of glass-ceramic composite board products is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

The invention relates to a green brick of a single-firing glass ceramic composite board. The green brick comprises a green body layer and a glass ceramic frit layer from bottom to top, and further comprises a fixing layer arranged on the surface of the glass ceramic frit layer, the fixing layer is formed by spraying a glass ceramic frit particle fixing agent, the glass ceramic frit particle fixing agent comprises the following components in percentage by weight: 3.8-4.8% of a nonionic polyurethane associated thickener, 1.8-2.4% of attapulgite clay, 0.6-1% of a defoamer, 0.6-1.6% of a dispersing agent and the balance of a solvent. When the green brick is used, a glass ceramic frit particle on the surface cannot be taken away by an air draught in a preheating zone in the firing, so that the waste is avoided, and the defect rate of a product of the glass ceramic composite board is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

ActiveCN104250109BSolve the problem of being easily sucked awayColor effects do not existBrickAdhesive

The invention relates to a green brick of a monofired glass ceramic composite plate. The green brick comprises a green body layer and a glass ceramic frit layer from bottom to top, a water repellent layer is further arranged between the green body layer and the glass ceramic frit layer, and the glass ceramic frit layer is formed in the way that a glass ceramic frit particle suspension liquid formed by mixing glass ceramic frit particles and a frit particle adhesive is applied to the surface of the water repellent layer; the frit particle adhesive comprises the following components by mass percent: 5.5-6.5 percent of a nonionic polyurethane associative thickener, 2.5-3.2 percent of silica, 1-1.4 percent of a defoamer, 1.2-1.8 percent of a dispersant and the balance of a solvent. The glass ceramic frit particles of the surface of the green brick structure are not taken away by a blower at a preheating zone during firing, so that waste is avoided and the defect rate of the glass ceramic composite plate product is reduced.

Owner:重庆高新技术产业研究院有限责任公司

Green brick of single-firing glass ceramic composite board

The invention relates to a green brick of a single-firing glass ceramic composite board. The green brick comprises a green body layer and a glass ceramic frit layer from bottom to top, and further comprises a fixing layer arranged on the surface of the glass ceramic frit layer, the fixing layer is formed by spraying a glass ceramic frit particle fixing agent, the glass ceramic frit particle fixing agent comprises the following components in percentage by weight: 5.0-6.0% of a vitamins thickener, 2.0-2.8% of attapulgite, 1.1-1.4% of a defoamer, 1.2-1.8% of a dispersing agent and the balance of a solvent. When the green brick is used, a glass ceramic frit particle on the surface cannot be taken away by an air draught in a preheating zone in the firing, so that the waste is avoided, and the defect rate of a product of the glass ceramic composite board is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

ActiveCN104591802BSolve the problem of being easily sucked awayColor effects do not existCelluloseGlass composites

The invention discloses a microcrystalline glass composite plate green brick formed by one-step sintering. The microcrystalline glass composite plate green brick comprises a green brick layer, a ground coat layer and a microcrystalline glass frit layer from bottom to top. The microcrystalline glass frit layer is formed by coating the surface of the ground coat layer with a microcrystalline glass frit particle suspension comprising microcrystalline glass frit particles and a microcrystalline glass frit particle binder. The microcrystalline glass frit particle binder comprises, by mass, 5.0-6.0% of a cellulose thickening agent, 2.0-2.8% of attapulgite, 1.1-1.4% of an antifoaming agent, 1.2-1.8% of a dispersant and the balance a solvent. The microcrystalline glass frit particles on the surface of the sintered green brick are not pumped by a fan of a preheating belt so that waste is avoided and a microcrystalline glass composite plate product defect rate is reduced.

Owner:张家港和智珅知识产权有限公司

A brick adobe fired into a glass-ceramic composite board at one time

The invention provides a green brick of a single fired glass ceramic composite board. The green brick comprises a green brick body layer, a ground coat layer and a glass ceramic frit layer from bottom to top, wherein the glass ceramic frit layer is formed by applying a microcrystalline frit particle suspension prepared by mixing glass ceramic frit particles with a frit particle binder to the surface of the ground coat layer; the frit particle binder comprises the following components by mass fraction: 5.5-6.5% of cellulosic thickening agents, 2.5-3.2% of white carbon black, 1.1-1.4% of defoaming agent, 1.2-1.8% of dispersing agents and the balance of solvents. By using the green brick, the glass ceramic frit particles on the surface can not be drawn away by a draught fan in a preheating zone during firing, thus avoiding waste and reducing the defect rate of glass ceramic composite board products.

Owner:张家港和智珅知识产权有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com