Green brick of single-firing glass ceramic composite board

A glass-ceramic and glass-ceramic frit technology, applied in the field of architectural ceramics, can solve the problems of low flatness, low yield, poor bonding effect of adhesives, etc. The effect of good water absorption and water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

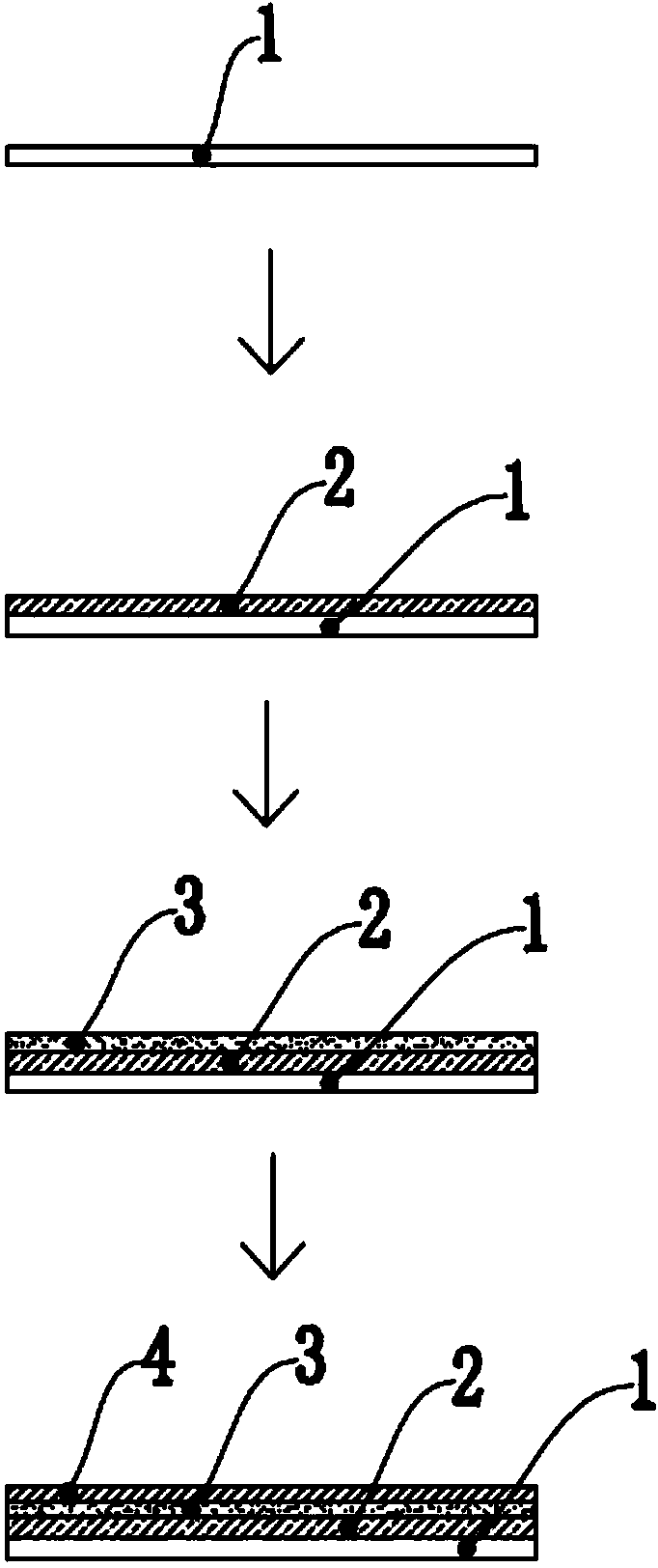

Method used

Image

Examples

preparation example Construction

[0021] Preparation of the bottom glaze: mix kaolin, quartz, potassium feldspar, albite, calcite, talc, dolomite, zinc oxide, zircon powder, and pyrophyllite with a thickness of less than 100 meshes as the bottom glaze raw material, add appropriate amount of water and 0.5% Sodium tripolyphosphate and 0.3% methyl cellulose are ground into a ball mill. The chemical composition of the bottom glaze is SiO2: 50%, Al2O3: 20%, CaO: 9%, MgO: 2%, K2O: 2%, Na2O: 3%, ZnO: 4%, ZrO2: 10%, and the fineness of the glaze slurry is 0.5% of the slurry bottom glaze on the 10,000-hole sieve for use. The amount of pyrophyllite in the bottom glaze is 3-5% of the total mass, because pyrophyllite has good water absorption and can absorb the solvent in the adhesive to prevent it from infiltrating into the brick body too much, thereby avoiding the subsequent transportation of the brick brick. Loss, usually, adopting the above method can reduce the green body conveying loss by 2-3%. It should be noted t...

Embodiment 1-1

[0026] The high-temperature transparent glass-ceramic frit particles (purchased from Quincy Carloby Glaze Company, 80 mesh) cloth are placed on the surface of the base glaze layer of the green body through the printing process, and then the microcrystalline prepared in one layer of embodiment 1 is sprayed. The glass frit particle fixative is sent into the kiln for firing at 1200°C, and the edges are ground and chamfered to obtain a finished glazed tile with uniform distribution and complete ice crystal texture. It should be noted that the high-temperature transparent glass-ceramic frit particles selected in Example 1-1 spread stably during the sintering process, forming a silver-white ice crystal texture pattern on the glaze layer, and the glass-ceramic frit particles can pass through The color glaze company purchases and obtains, and similar frit products can also realize this scheme.

Embodiment

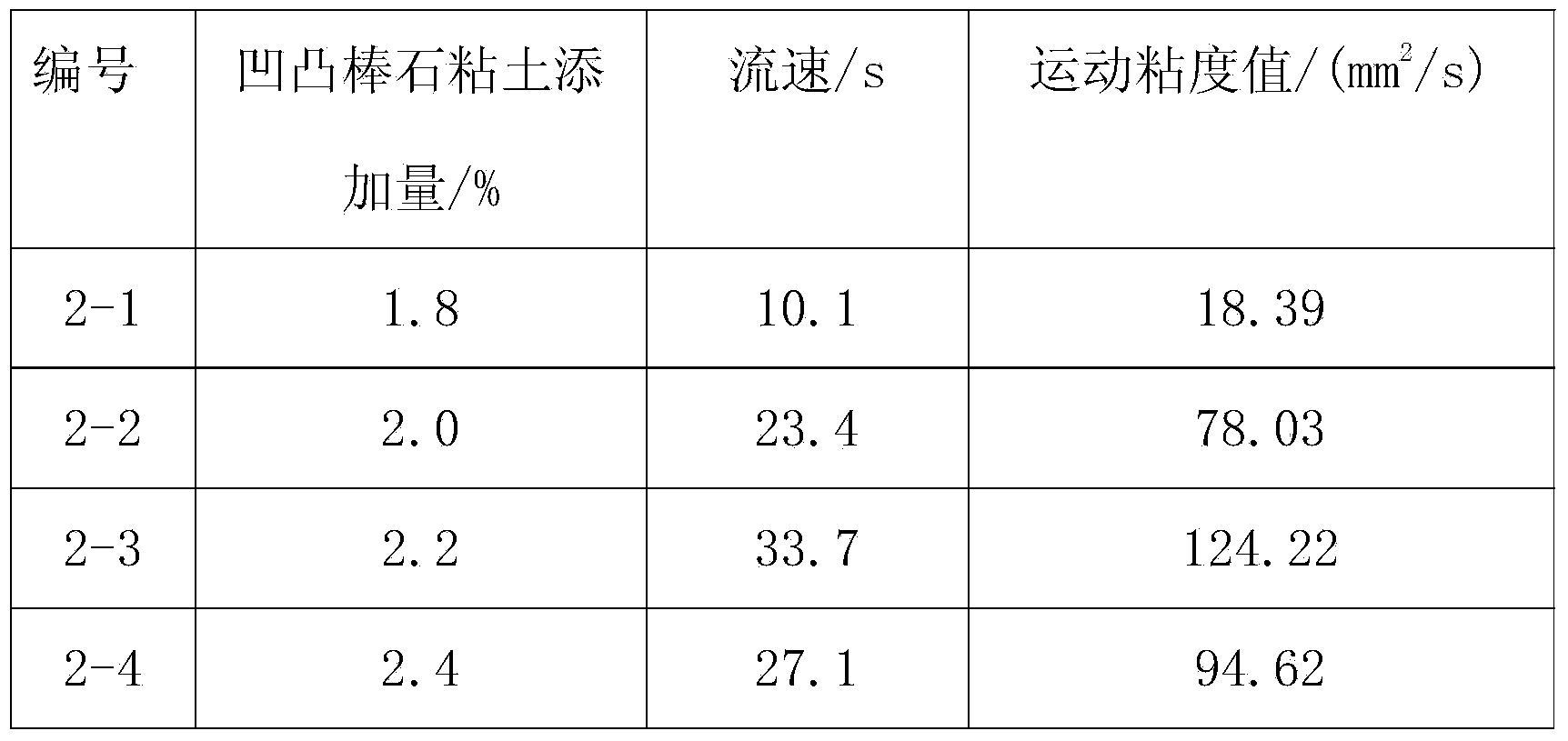

[0034] Example Group 2 - Effect of Attapulgite Clay Content on the Viscosity of Polyurethane Fixatives

[0035] The component of every 100kg polyurethane fixative: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) 4.3kg, attapulgite clay content is added as follows table 2, polyether type GPE Defoamer (purchased from Hangzhou Feier Chemical Industry Co., Ltd.) 0.6kg, sodium tripolyphosphate 1.2kg, the balance is diethylene glycol ether.

[0036]The preparation method of the above-mentioned polyurethane fixing agent comprises the following steps: 1) dissolving the nonionic polyurethane associative thickener in water, and stirring evenly; 2) adding attapulgite clay, and mixing evenly; 3) adding polyether-type GPE The defoamer and sodium tripolyphosphate were stirred evenly to obtain a polyurethane fixative, and the flow rate of the prepared polyurethane fixative was tested.

[0037] Table 2 Effect of the amount of attapulgite clay added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com