A kind of adobe fired into a glass-ceramic composite board at one time

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve problems such as low yield, low flatness, and affecting the quality and aesthetics of glass-ceramic composite panels, achieving high yield, The effect of the color effect does not exist to affect the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

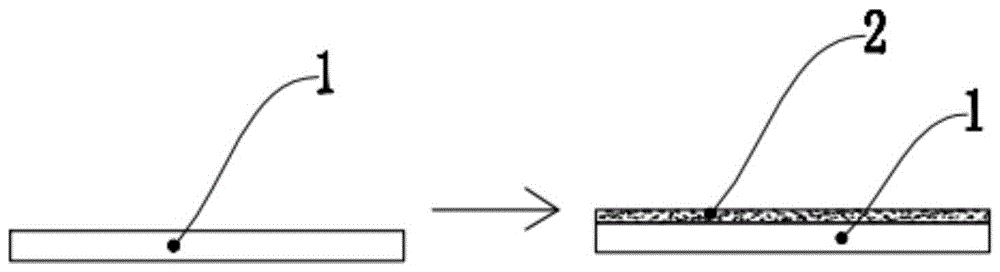

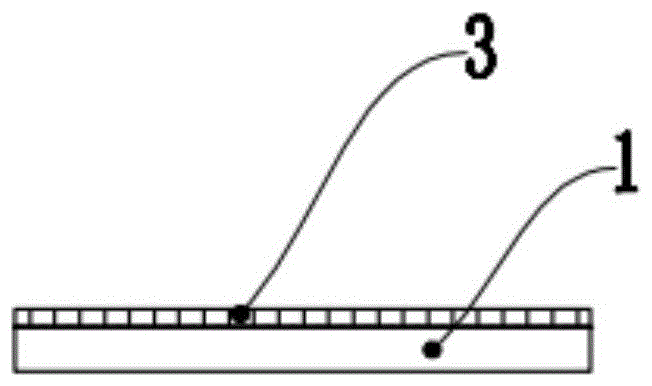

Method used

Image

Examples

Embodiment 1

[0024] The components of each 100kg frit granule binder: hydroxyethyl cellulose (purchased by Guangzhou Moke Building Material Technology Co., Ltd.) 5.5kg, white carbon black 2.5kg, polymethylsiloxane 1.1kg, silicone modified phosphoric acid Sodium is 1.7kg, the balance is water.

[0025] The preparation method of the above-mentioned frit particle binder includes the following steps: a) dissolving hydroxyethyl cellulose in water and stirring uniformly; b) adding polymethylsiloxane and organic silicon-modified sodium phosphate, and stirring uniformly; c) Add white carbon black and remaining water solvent, stir evenly to obtain frit granule binder, and measure its flow rate to be 25.7s (30°C, 4 cups). It should be noted that the silicone modified sodium phosphate can be replaced by sodium polyacrylate or sodium hexametaphosphate as a dispersant, and this solution can also be realized.

[0026] Preparation of bricks of glass-ceramic composite board-Example 1-1

[0027] Add 375kg of si...

Embodiment 2

[0046] The preparation method of this embodiment is basically the same as that of Embodiment 1, except that the components and ratios used in this embodiment are different. The components of each 100kg frit granule binder: hydroxyethyl methylcellulose (Dezhou Kangrong Chemical Co., Ltd.) 6.5kg, white carbon black 3.2kg, polymethylsiloxane 1.4kg, sodium hexametaphosphate 2.1 kg, the balance is ethanol.

Embodiment 2-1

[0048] Add 375kg silver white ice crystal glass frit particles (purchased from Quincy Carrobie Glaze Company, fineness 100-150 mesh) into 125kg frit particle binder prepared in Example 2, and mix Evenly, a suspension of glass-ceramic frit particles is obtained. The solid content of the glass-ceramic frit particles is 70%, no visible bubbles, and the flow rate is 43.6s (30℃, coated with 4 cups). There is no delamination after the suspension is placed for 5 days Phenomenon, it can be seen that the frit particle binder of the present invention and the glass-ceramic frit particles still have good stability after being mixed. It should be noted that the silver-white ice crystal glass frit particles selected in this embodiment 2-1 spread during the sintering process to form silver-white ice crystal flowers on the surface glaze layer. The glass-ceramic frit particles It can be purchased through the color glaze company, and similar frit products can also realize this scheme.

[0049] Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com