A brick adobe fired into a glass-ceramic composite board at one time

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve problems such as low yield, low flatness, and affecting the quality and aesthetics of glass-ceramic composite panels, achieving high yield, The effect of the color effect does not exist to affect the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

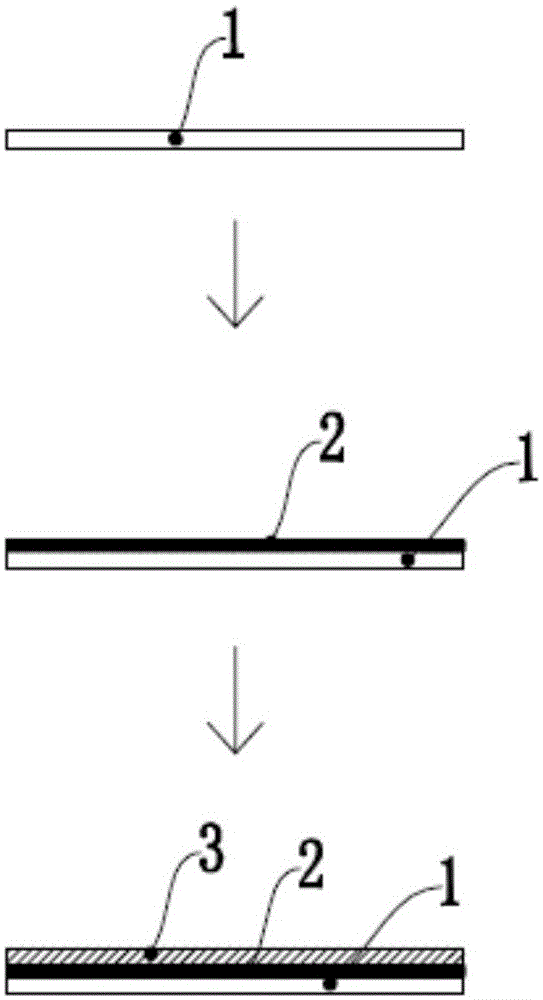

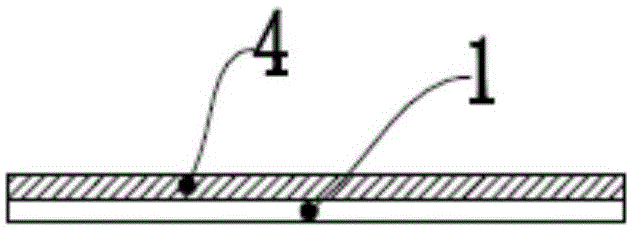

[0033] A method for preparing a once-fired transparent glass-ceramic composite board, comprising the following steps:

[0034] A. Green body stamping and forming: After the green body powder (fineness is 150 degrees) and micropowder powder (fineness is 150 degrees) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 2 of the thickness of the bottom layer, dry;

[0035] B. Spray a layer of hydrophobic layer: spray a layer of modified polyvinyl alcohol water repellent (purchased from Jinan Yuekai Chemical Co., Ltd.) on the surface of the green body;

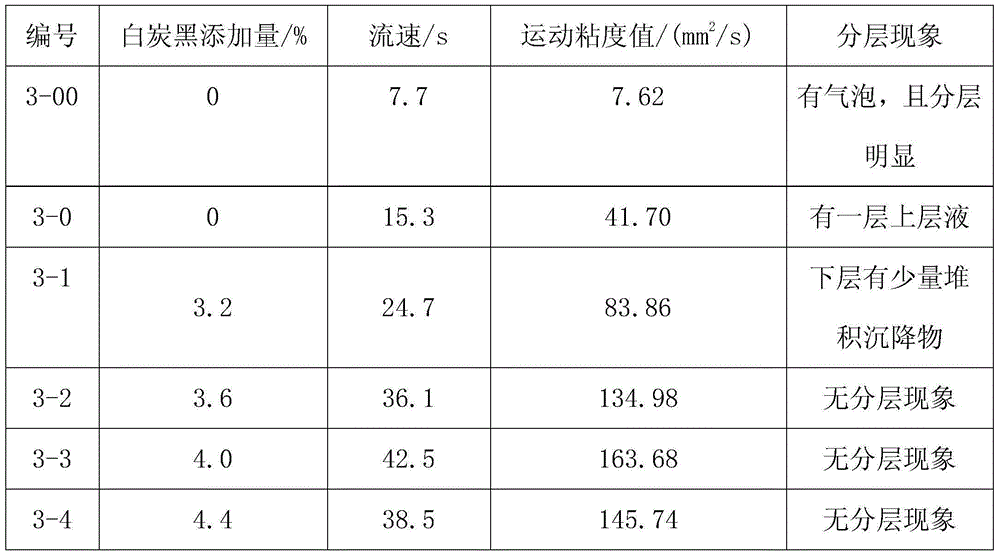

[0036] C, applying glass-ceramic frit particle suspension: the glass-ceramic frit particle (purchasing from Quincy Carloby Glaze Company, fineness 70 orders) of 375kg silvery-white ice crystal effect is added to embodiment group 1 and makes In 125kg of frit particle binder, mix evenly to obtain glass-ceramic frit particle suspension, the solid c...

Embodiment 1-2

[0041] A method for preparing a once-fired transparent glass-ceramic composite board, comprising the following steps:

[0042] A. Green body stamping and forming: After the green body powder (fineness is 150 mesh) and micropowder powder (fineness is 150 mesh) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 2 of the bottom base layer thickness, dry;

[0043]B, applying glass-ceramic frit: the glass-ceramic frit particles of 375kg silver-white ice crystal effect (purchase from Quincy Carloby Glaze Company, fineness 70 orders) is added the frit of 125kg that embodiment group 1 makes In the block particle binder, mix evenly to obtain a suspension of glass-ceramic frit particles. The solid content of glass-ceramic frit particles is 84%, no visible bubbles, and the flow rate is 46.2s (30°C, coated with -4 cups). There is still no delamination phenomenon after the solution is placed for 5 days...

Embodiment 2

[0073] A method for preparing a once-fired transparent glass-ceramic composite board, comprising the following steps:

[0074] A. Green body stamping and forming: After the green body powder (fineness is 70 degrees) and micropowder powder (fineness is 100 degrees) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 3 of the bottom base layer thickness, dry;

[0075] B. Spray water-repellent: Spray a layer of modified polyvinyl alcohol water-repellent (purchased from Jinan Yuekai Chemical Co., Ltd.) on the surface of the green body;

[0076] C, applying glass-ceramic frit: 375kg transparent glass-ceramic frit particles (purchased from Quincy Carloby Glaze Company, fineness 90 orders) are added to the 125kg frit particles that embodiment group 1 makes to bond In the mixture, mix evenly to obtain a suspension of glass-ceramic frit particles. The solid content of glass-ceramic frit particles is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com