Green brick of single-firing glass ceramic composite board

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve the problems of low yield, low flatness, affecting the quality and aesthetics of glass-ceramic composite boards, and achieves no color effect Effect, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of bottom glaze: Mix kaolin, quartz, potassium feldspar, albite, calcite, talc, dolomite, zinc oxide and zircon powder as raw materials for bottom glaze, add appropriate amount of water and 0.5% tripolymer Sodium phosphate, 0.3% methyl cellulose, ball milled into the chemical composition of SiO2: 50%, Al2O3: 20%, CaO: 9%, MgO: 2%, K2O: 2%, Na2O: 3%, ZnO: 4 %, ZrO2: 10%, and the fineness is 0.5% of the slurry bottom glaze on the 10,000-hole sieve for use.

[0031] It should be noted that the preparation of green body powder, micropowder formula components and bottom glaze given here can be replaced by other formula components in the common knowledge, and all can be applied to the composite glass-ceramics of the present invention. In the preparation method of the plate. The bottom glaze mainly serves as a covering function, so the make-up soil with high whiteness is usually selected, and its expansion and contraction coefficient during firing is between the g...

Embodiment 1

[0035] Components of each 100kg of glass-ceramic frit particle fixative: 5.0kg of hydroxyethyl cellulose (purchased by Guangzhou Moke Building Materials Technology Co., Ltd.), 2.5kg of attapulgite, 1.1kg of polymethylsiloxane, silicone modified Sodium phosphate 1.7kg, the balance is water.

[0036] The preparation method of the above-mentioned frit granule binder comprises the following steps: a) dissolving hydroxyethyl cellulose in water, and stirring evenly; b) adding polymethylsiloxane and organic silicon-modified sodium phosphate, and stirring evenly; c) Add attapulgite and the remaining water solvent, and stir evenly to obtain a frit particle binder. The measured flow rate is 26.8s (30°C, coated with -4 cups). It should be noted that the organosilicon-modified sodium phosphate can be replaced by sodium polyacrylate or sodium hexametaphosphate as a dispersant, and this solution can also be realized.

Embodiment 1-1

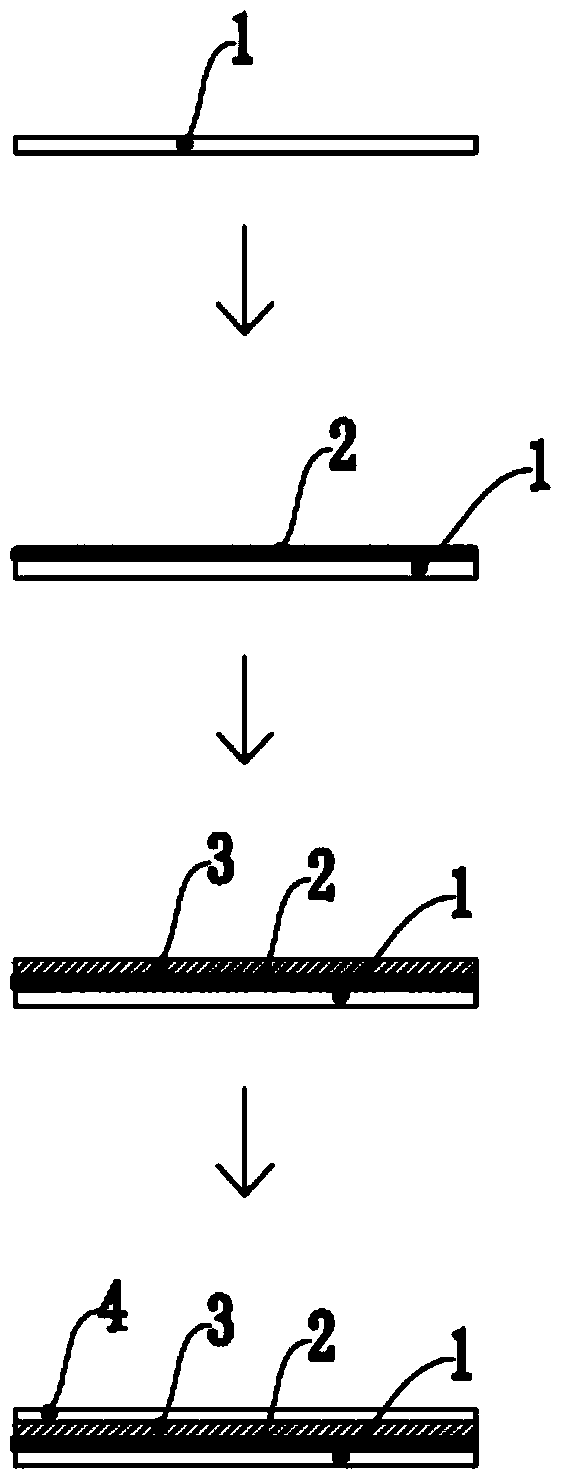

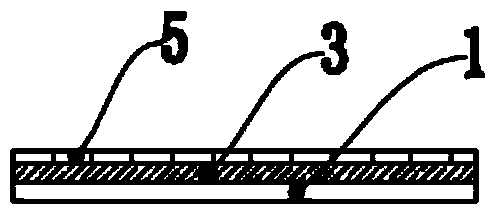

[0038] A method for preparing a once-fired transparent glass-ceramic composite board, comprising the following steps:

[0039] A. Green body stamping and forming: After the green body powder (fineness is 150 mesh) and micropowder powder (fineness is 150 mesh) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 2 of the thickness of the bottom layer, dry;

[0040] B. Spray a layer of water-repellent layer 2: Spray a layer of silicone water-repellent on the surface of the green body;

[0041] C. Glaze printing;

[0042] D, applying glass-ceramic frit particle suspension: the glass-ceramic frit particle (purchasing from Quincy Carloby glaze company, fineness 100 orders) of 375kg silver-white ice crystal effect is added 125kg that embodiment 1 makes In the frit particle binder, mix evenly to get glass-ceramic frit particle suspension, the solid content of glass-ceramic frit particles is 75%, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com