A kind of frit particle binder and preparation method thereof

A frit particle and binder technology, which is applied in the field of architectural ceramics, can solve the problem of easily being sucked off the frit particle binder, achieve the effect of no influence on the color effect and avoid pinholes and bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

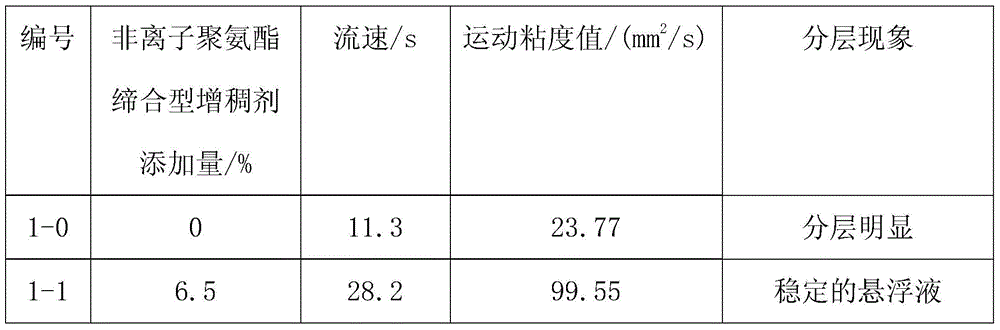

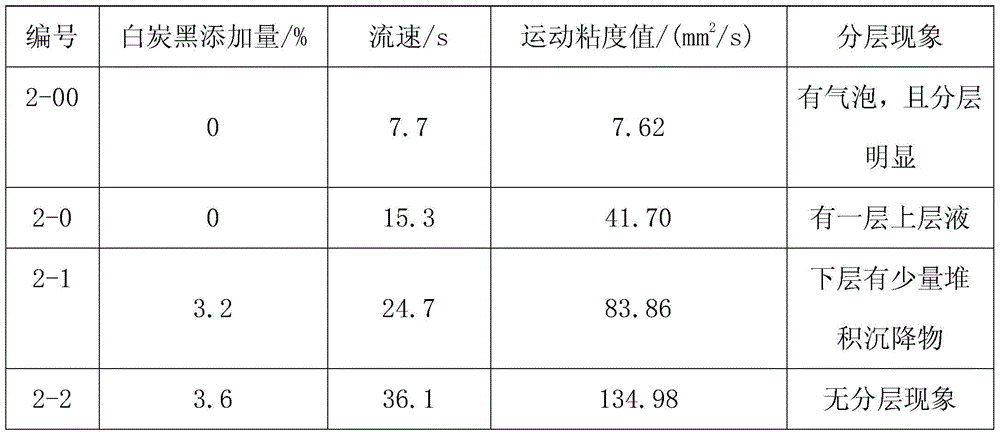

[0027] Preparation of Frit Particle Binder - Example Group 1

[0028] Components of per 100kg frit granule binder: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) content is added as shown in Table 1, white carbon black 3.8kg, polyether type GPE defoamer (purchased from Hangzhou Phil Chemical Industry Co., Ltd.) 1.3kg, sodium tripolyphosphate 0.3kg, and the balance is an aqueous solution of ethanol.

[0029] Above-mentioned frit particle binder is prepared according to the following steps:

[0030] A, add 3.8kg white carbon black and be dissolved in the ethanol of its quality 4-5 times, stir evenly;

[0031] B, add nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) and remaining ethanol by table 1, stir; The purpose of saving costs and reducing work risks)

[0032] C. Add 1.3kg of polyether type GPE defoamer (purchased from Hangzhou Feier Chemical Industry Co., Ltd.) and 0.3kg of sodium tri...

Embodiment 2

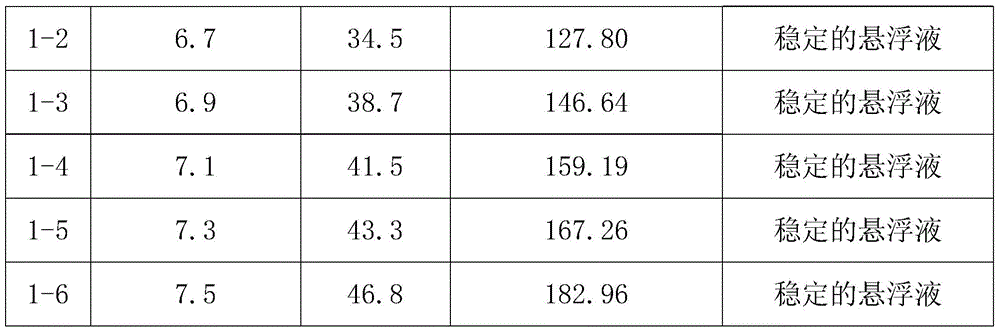

[0042] Components of per 100kg frit particle binder: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) 7.5kg, white carbon black content is added as shown in Table 2, polyether type GPE defoamer (purchased from Hangzhou Phil Chemical Industry Co., Ltd.) 1.3kg, sodium tripolyphosphate 1kg, and the balance is an aqueous solution of ethanol.

[0043] Above-mentioned frit particle binder is prepared according to the following steps:

[0044] A. Add white carbon black according to the amount of white carbon black added in Table 2, and dissolve it in ethanol with 5 times its mass, and stir evenly;

[0045] B, add 7.5kg nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) and the water of surplus, stir;

[0046] C, add polyether type GPE defoamer (purchase from Hangzhou Feier Chemical Industry Co., Ltd.) 1.3kg and sodium tripolyphosphate 1kg, stir evenly for 65min, obtain frit particle binder;

[0047]...

Embodiment 4-1

[0073] The frit particles (purchased from Quincy Carloby Glaze Company, 60 orders) cloth with silver-white ice crystals are placed on the body surface through the printing process, and then the frit particles that are sprayed with one layer of embodiment 4 are bonded It is sent into the kiln for firing at 1200°C, and the edges are ground and chamfered to obtain a finished glazed tile with uniform distribution and complete ice crystal texture. It should be noted that the frit particles with silver-white ice crystals selected in Example 4-1 spread stably during the sintering process, forming a silver-white ice crystal texture pattern on the glaze layer, and the frit particles can pass through the glaze. The company purchased it, and similar frit products can also realize this plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com