A brick adobe fired into a glass-ceramic composite board at one time

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve problems such as low yield, low flatness, and missing particles of glass-ceramic frit, and achieve high yield and good color effect. The effect of having an influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

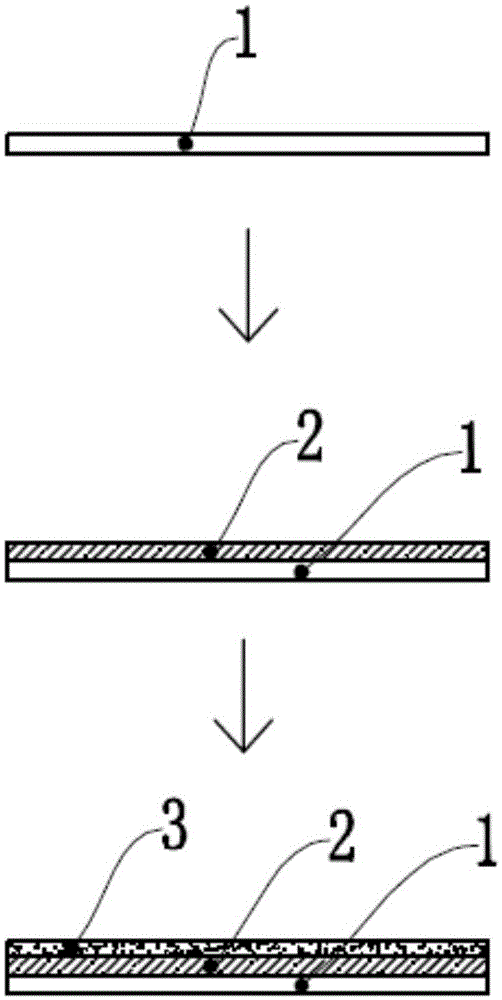

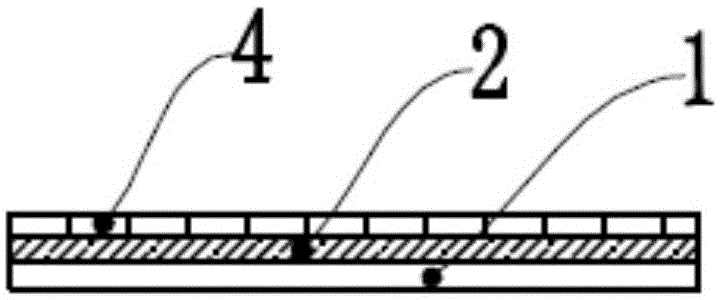

Method used

Image

Examples

Embodiment 1-1

[0027] The glass-ceramic frit particle of 375kg silver-white ice crystal effect (purchase from Quincy Caroby Glaze Company, fineness 70 orders) is added in the frit particle binder of 125kg that embodiment group 1 makes, mix homogeneously , to obtain glass-ceramic frit particle suspension, the solid content of glass-ceramic frit particles is 75%, no visible bubbles, the flow rate is 45.3s (30 ℃, coated with -4 cups), and there is still no stratification after the suspension is placed for 5 days , it can be seen that the frit particle binder of the present invention still has good stability after mixing with the glass-ceramic frit particles. It should be noted that the glass-ceramic frit particles with silver-white ice crystal effect selected in Example 1-1 spread during the sintering process, forming the effect of silver-white ice crystal flowers on the glaze layer, and the glass-ceramic frit particles It can be purchased through the color glaze company, and similar frit produ...

Embodiment 2

[0038] Components of every 100kg frit granule binder: nonionic polyurethane associative thickener (NaeWoiKorea., Ltd. company, model HIRESOL85) content is added as shown in Table 1, attapulgite clay 2.0kg, polyether type GPE Defoamer (purchased from Hangzhou Feier Chemical Industry Co., Ltd.) 1kg, sodium tripolyphosphate 1.6kg, and the balance is water.

[0039]350kg has the glass-ceramic frit particle of milky white ice crystal effect (purchasing from Quincy Carroby Glaze Company, fineness 110 orders) is added in the frit particle binder of 150kg that embodiment 2 makes, mix homogeneously, A glass-ceramic frit particle suspension was obtained. The solid content of the glass-ceramic frit particles was 70%, and there were no visible bubbles. The suspension was left for 5 days. See Table 2 for the flow rate and stratification.

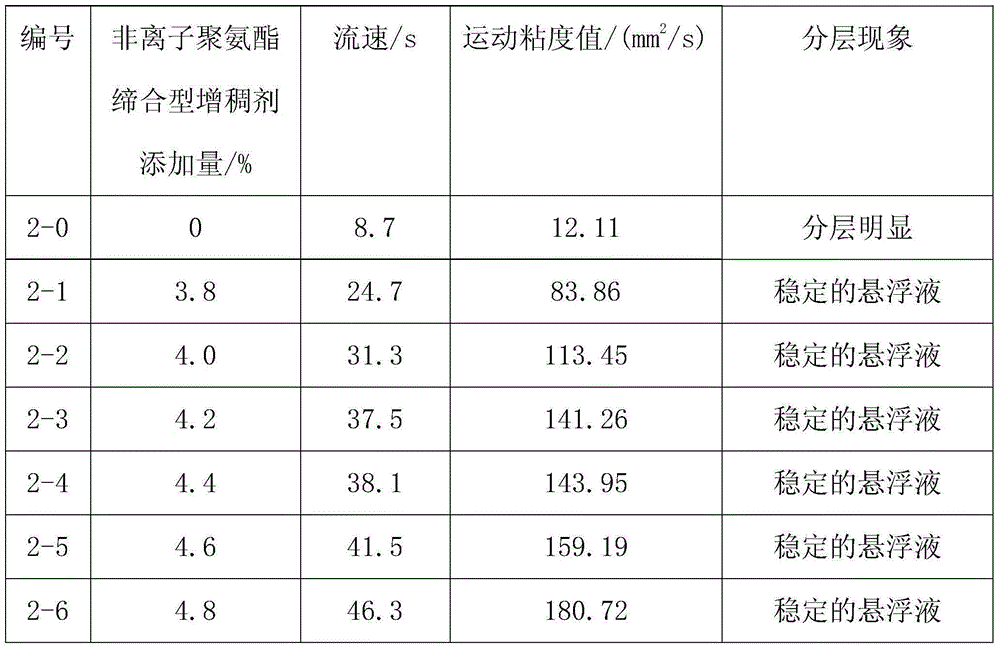

[0040] Table 2 Research on the amount of nonionic polyurethane associative thickener added

[0041]

[0042] From Table 2, the addition amount of th...

Embodiment 3-00

[0049] The frit granules of 375kg green ice crystal effect (purchased from Quincy Carloby Glaze Company, fineness 100 mesh) are added in the 125kg viscous water slurry prepared by sodium carboxymethyl cellulose, mix well, get frit granules Suspension, frit particle solid content 75%, left for 5 days, flow rate and stratification phenomenon are shown in Table 3.

[0050] Table 3 Effect of attapulgite clay content on the delamination phenomenon of suspension

[0051]

[0052] It can be obtained from Table 3 that the viscosity value of the viscous water slurry formulated with sodium carboxymethyl cellulose is not high, which cannot effectively prevent the glass-ceramic frit particles from being sucked away by low negative pressure, and there is bubble phenomenon, which is different from that of glass-ceramic The suspension after mixing the frit particles cannot be stored for a long time. In addition, the addition of attapulgite clay increases the thickening efficiency of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com