Green brick of one-step sintered glass-ceramic composite board

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve the problems of low yield, pinholes or dissolution holes, and low flatness, etc., and achieve high yield and no influence on color effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Preparation of bottom glaze: Mix kaolin, quartz, potassium feldspar, albite, calcite, talc, dolomite, zinc oxide and zircon powder as raw materials for bottom glaze, add appropriate amount of water and 0.5% tripolymer Sodium phosphate, 0.3% methyl cellulose, ball milled into the chemical composition of SiO2: 50%, Al2O3: 20%, CaO: 9%, MgO: 2%, K2O: 2%, Na2O: 3%, ZnO: 4 %, ZrO2: 10%, and the fineness is 0.5% of the slurry bottom glaze on the 10,000-hole sieve for use. It should be noted that the green body powder and the preparation of the bottom glaze given here can be replaced by other formula components in the common knowledge, and can be applied to the preparation method of the single-firing glass-ceramic composite plate of the present invention. .

[0022] Example group 1

Embodiment 1-1

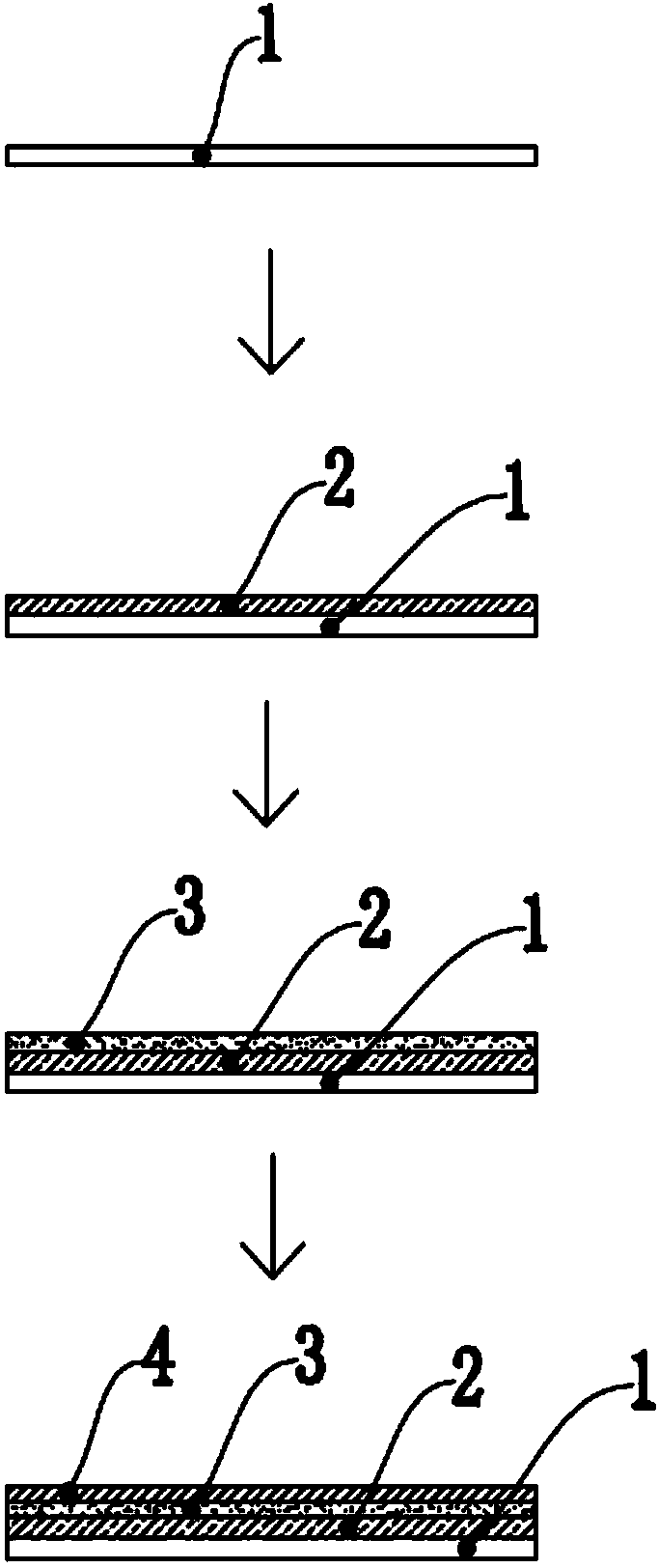

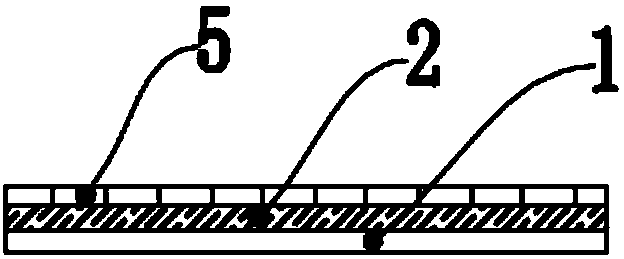

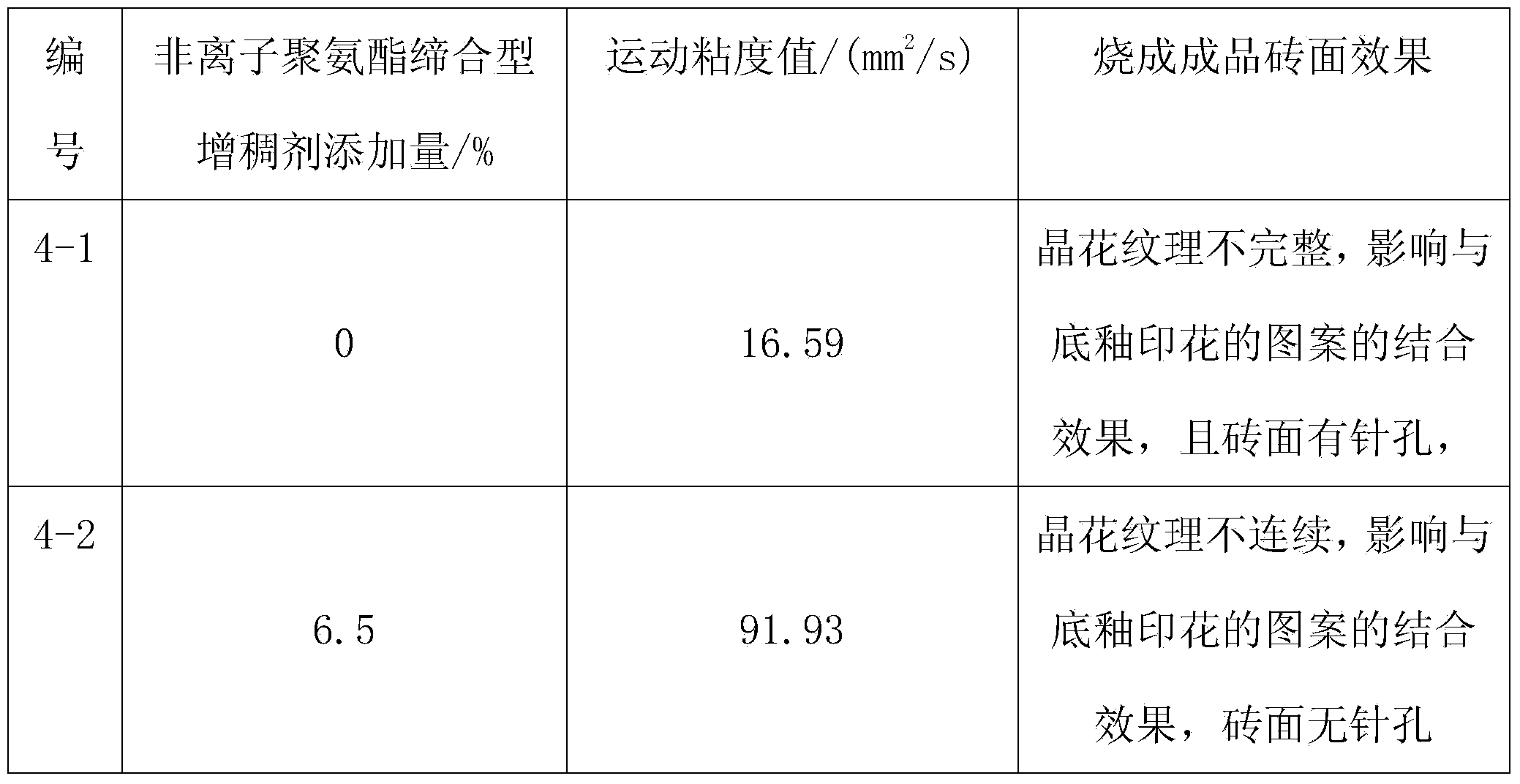

[0026] The high-temperature transparent glass-ceramic frit particles (purchased from Quincy Carloby Glaze Co., 90 mesh) cloth are placed on the surface of the underglaze layer of the green body through the printing process, and then the microcrystalline prepared in one layer of embodiment 1 is sprayed. glass frit particle fixative, obtained as figure 1 The adobe shown includes a green body layer 1, an underglaze layer 2, a glass-ceramic frit particle layer 3 and a fixing agent 4, and enters the firing process. Sent into the kiln for firing at 1200°C, grinding and chamfering to obtain finished glazed tiles with uniform distribution and complete ice crystal texture, such as figure 2 The shown glass-ceramic composite board has a green body layer 1, an underglaze layer 2 and a glass-ceramic layer 5. It should be noted that the high-temperature transparent glass-ceramic frit particles selected in Example 1-1 are in the sintering process. Medium and stable spreading, forming a sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com