A brick adobe fired into a glass-ceramic composite board at one time

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve the problems of low yield, pinholes or melting holes, and low flatness, etc., and achieve high yield and no influence on color effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The components of each 100kg glass-ceramic frit particle fixing agent: hydroxyethyl cellulose (purchased by Guangzhou Moke Building Material Technology Co., Ltd.) 5.0kg, attapulgite 2.5kg, polymethylsiloxane 1.1kg, silicone modified 1.7 kg of sodium phosphate, the balance is water.

[0023] The preparation method of the above-mentioned frit particle binder includes the following steps: a) dissolving hydroxyethyl cellulose in water and stirring uniformly; b) adding polymethylsiloxane and organic silicon-modified sodium phosphate, and stirring uniformly; c) Add attapulgite and the remaining water solvent, stir evenly to obtain a frit granular binder, and measure its flow rate to be 26.8s (30°C, 4 cups). It should be noted that the organosilicon-modified sodium phosphate can be replaced by sodium polyacrylate or sodium hexametaphosphate as a dispersant, and this solution can also be realized.

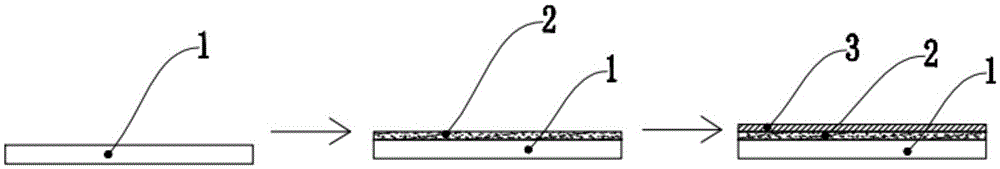

[0024] Preparation of bricks of glass-ceramic composite board-Example 1-1

[0025] P...

Embodiment 2

[0041] The preparation method of this embodiment is basically the same as that of Embodiment 1, except that the components and ratios used in this embodiment are different. The components of each 100kg frit granule binder: hydroxyethyl methylcellulose (Dezhou Kangrong Chemical Co., Ltd.) 5.5kg, attapulgite 3.0kg, polymethylsiloxane 1.4kg, sodium hexametaphosphate 2.1 kg, the balance is ethanol.

Embodiment 2-1

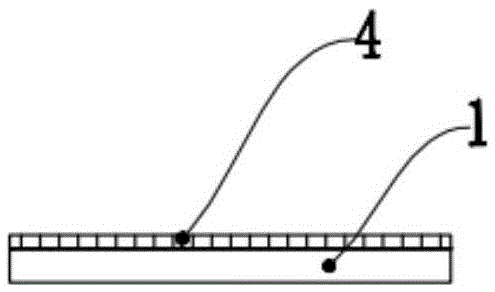

[0043] Place high-temperature transparent glass-ceramic frit particles (purchased from Quincy Carrobie Glaze Company, 100-200 mesh) on the surface of the printed body, and then spray a layer of the glass-ceramic prepared in Example 2 Frit particle fixing agent, you can get the required bricks (such as figure 2 As shown, the body layer 1 and the glass-ceramic layer 4) are included. This kind of brick can be sent into a kiln to be fired at 1170°C, and the edges and corners are ground and chamfered to obtain a finished product of the glass-ceramic composite plate with uniform distribution and complete ice crystal texture. The bricks provided by the present invention can avoid the adverse effects (such as pinholes, lack of decorative effects, etc.) caused by the negative pressure of the preheating zone on the adsorption of frit particles during firing. It should be noted that the high-temperature transparent glass-ceramic frit particles selected in this embodiment 2-1 spread stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com