Cubic boron nitride/ titanium carbide compound sintered cutter material and preparation method thereof

A technology of cubic boron nitride and tool material, applied in the field of cubic boron nitride/titanium carbide composite sintered tool material and its preparation, can solve the problems of short tool life, poor hardness and wear resistance, easy to wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Cubic boron nitride / titanium carbide composite sintered tool material, which is made by sintering the following raw materials in parts by weight:

[0022] Cubic boron nitride microcrystals with a particle size of 1-20 μm 40-70

[0023] Titanium carbide crystallites with a particle size of 1 to 4 μm 30 to 50

[0024] Silicon powder with a particle size of 1-3μm 0.05-0.5

[0025] Toner finer than 300 mesh 0.05~0.5

[0026] Tungsten carbide powder with particle size 1~3μm 0.1~2

[0027] Aluminum powder with a particle size of 2-10 μm 1-10.

[0028] Its preparation method is as follows:

[0029] (1) Clinker preparation: weigh the main components and additive components according to the above ratio, and mix them uniformly for 10 to 30 hours in a commonly used mixer to make clinker.

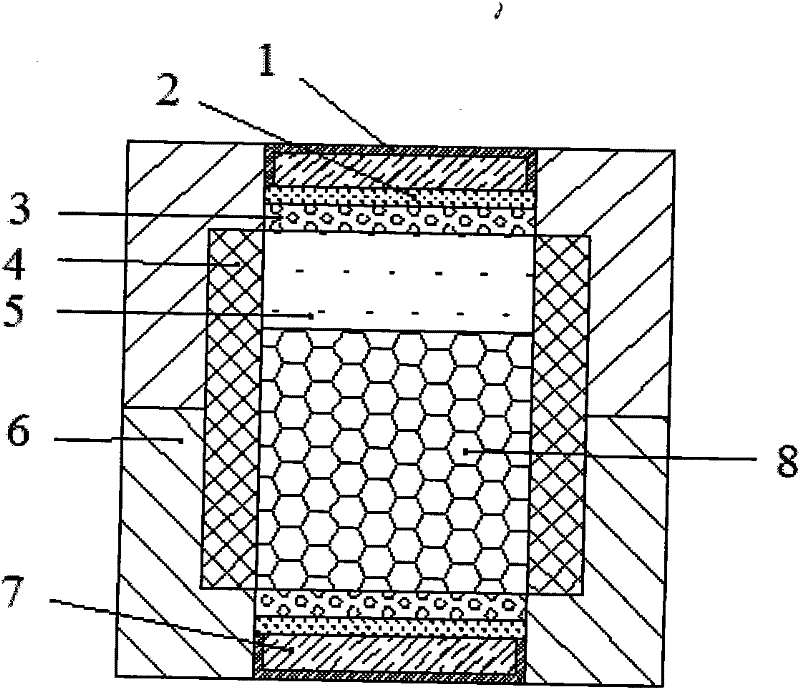

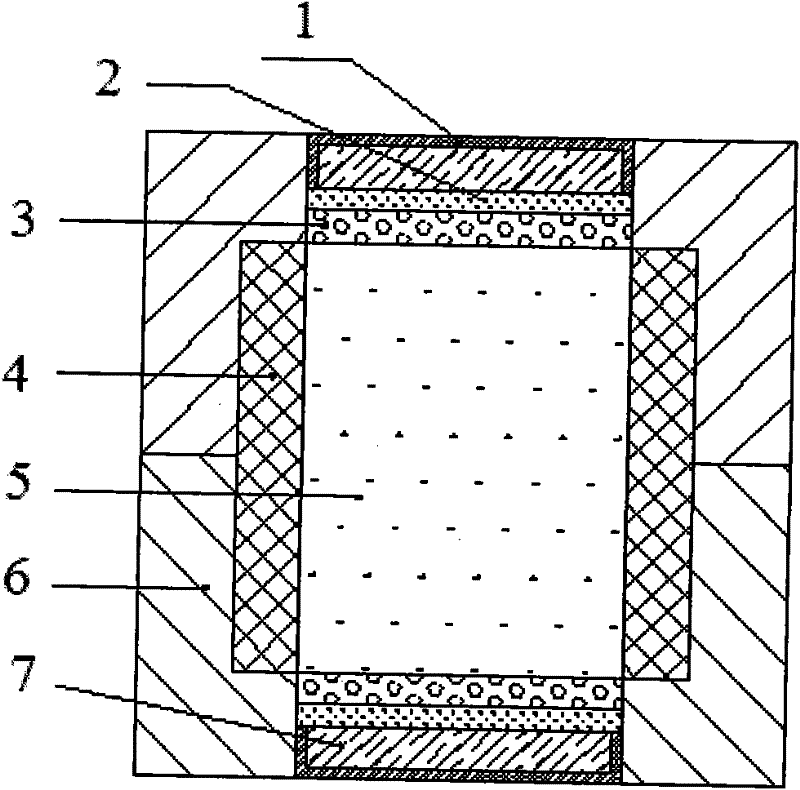

[0030] (2) Assembly: Place the clinker on the clean surface of the treated hard alloy, put it into the mold together with the hard alloy, and make a composite blank of CBN-TiC composite sin...

Embodiment 2

[0034] Cubic boron nitride / titanium carbide composite sintered tool material, which is made by sintering the following raw materials in parts by weight:

[0035] Cubic boron nitride microcrystals with a particle size of 1-20 μm 40

[0036] Titanium carbide crystallites with a particle size of 1-4 μm 50

[0037] Silicon powder with a particle size of 1-3 μm 0.05

[0038] Toner finer than 300 mesh 0.5

[0039] Tungsten carbide powder with particle size 1~3μm 2

[0040] Aluminum powder 1 with a particle size of 2-10 μm.

[0041] Its preparation method is as follows:

[0042] (1) Clinker preparation: weigh the main components and additive components according to the above ratio, and mix them uniformly for 10 to 30 hours in a commonly used mixer to make clinker.

[0043] (2) Assembly: Place the clinker on the clean surface of the treated hard alloy, put it into the mold together with the hard alloy, and make a composite blank of CBN-TiC composite sintered compact body and hard...

Embodiment 3

[0047] Cubic boron nitride / titanium carbide composite sintered tool material, which is made by sintering the following raw materials in parts by weight:

[0048] Cubic boron nitride microcrystals with a particle size of 1-20 μm 45

[0049] Titanium carbide crystallites with a particle size of 1-4 μm 45

[0050] Silicon powder with a particle size of 1-3 μm 0.1

[0051] Toner finer than 300 mesh 0.2

[0052] Tungsten carbide powder with particle size 1~3μm 1.5

[0053] Aluminum powder with a particle size of 2 to 10 μm 5.

[0054] Its preparation method is as follows:

[0055] (1) Clinker preparation: weigh the main components and additive components according to the above ratio, and mix them uniformly for 10 to 30 hours in a commonly used mixer to make clinker.

[0056] (2) Assembly: Place the clinker on the clean surface of the treated hard alloy, put it into the mold together with the hard alloy, and make a composite blank of CBN-TiC composite sintered compact body and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com