Method for preparing microlite from ceramic waste and microlite

A technology of ceramic waste and microcrystalline stone, applied in the field of method and microcrystalline stone, can solve the problems such as the inability to manufacture microcrystalline stone, and achieve the effect of high flatness and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

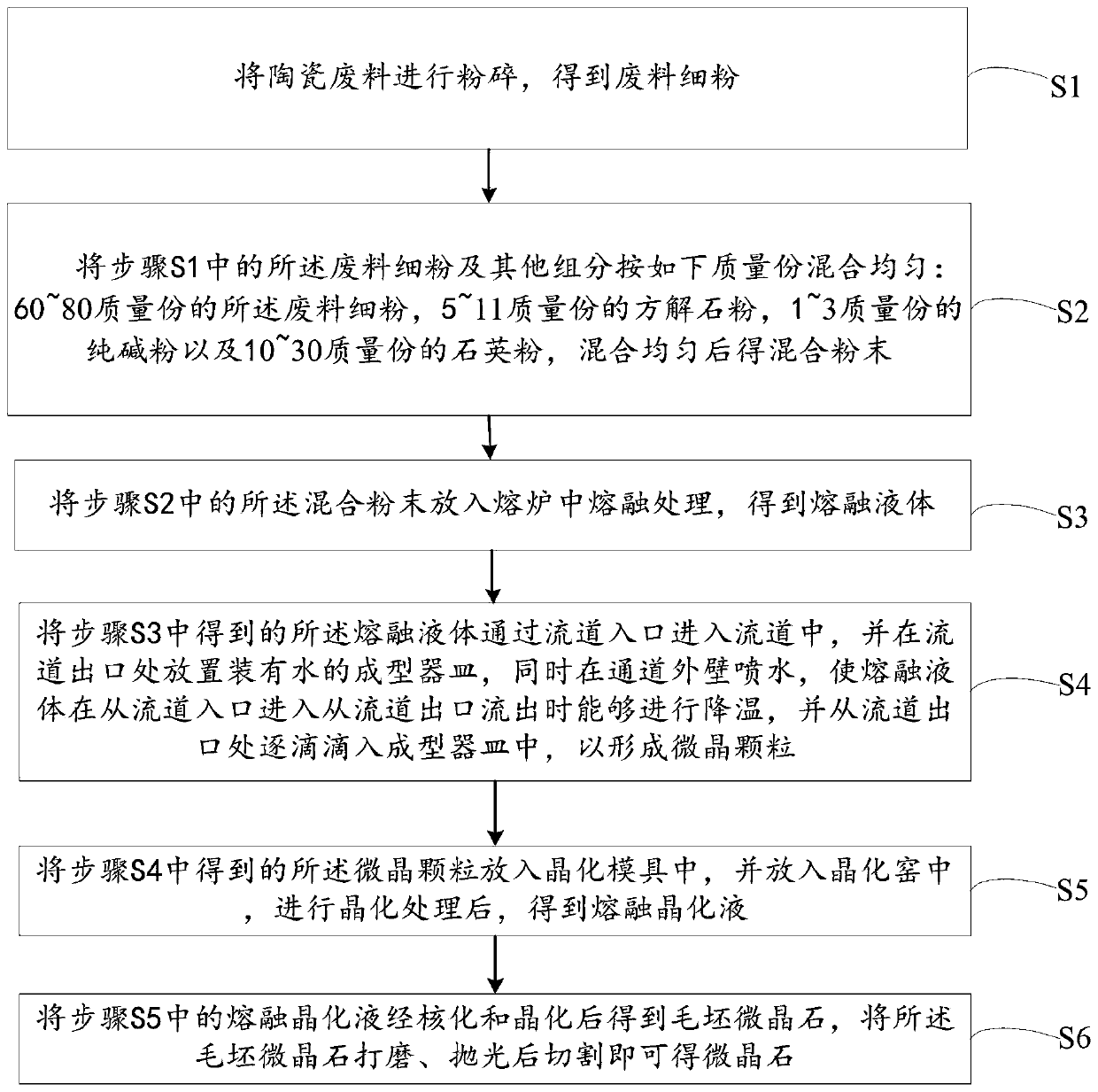

Method used

Image

Examples

Embodiment 1

[0051]Take 60g of ceramic waste and crush it into 50 meshes, mix it with 5g of calcite powder, 1g of soda ash powder and 10g of quartz powder, put it into the melting furnace, and melt it at a melting temperature of 1500° and a melting time of 2.5 hours Finally, the molten liquid is obtained, and it enters the flow channel through the flow channel inlet, and a forming vessel filled with water is placed at the flow channel outlet, and water is sprayed on the outer wall of the channel at the same time, so that the molten liquid flows out from the flow channel outlet after entering from the flow channel inlet. The temperature can be lowered to 1000 ° at the same time, and drop into the forming vessel from the outlet of the flow channel to form microcrystalline particles, then put the microcrystalline particles into the crystallization mold, and put them into the crystallization kiln, with the sintering temperature as 1000°, the sintering time is 2 hours to obtain the molten crysta...

Embodiment 2

[0053] Take 70g of ceramic waste and crush it into 200 meshes, and mix it with 11g of calcite powder, 2g of soda ash powder and 20g of quartz powder, put it into the furnace, and melt it at a melting temperature of 1400° and a melting time of 1.5 hours Finally, the molten liquid is obtained, and it enters the flow channel through the flow channel inlet, and a forming vessel filled with water is placed at the flow channel outlet, and water is sprayed on the outer wall of the channel at the same time, so that the molten liquid flows out from the flow channel outlet after entering from the flow channel inlet. The temperature can be lowered to 1100 ° at the same time, and drop into the forming vessel from the outlet of the flow channel to form microcrystalline particles, then put the microcrystalline particles into the crystallization mold, and put them into the crystallization kiln, with the sintering temperature as 1200°, the sintering time is 3 hours to obtain the molten crystal...

Embodiment 3

[0055] Take 80g of ceramic waste and crush it into 350 meshes, mix it with 8g of calcite powder, 3g of soda ash powder and 30g of quartz powder, put it into the furnace, and melt it at a melting temperature of 1600° and a melting time of 2 hours Finally, the molten liquid is obtained, and it enters the flow channel through the flow channel inlet, and a forming vessel filled with water is placed at the flow channel outlet, and water is sprayed on the outer wall of the channel at the same time, so that the molten liquid flows out from the flow channel outlet after entering from the flow channel inlet. The temperature can be lowered to 1200 ° at the same time, and drop into the forming vessel from the outlet of the flow channel to form microcrystalline particles, then put the microcrystalline particles into the crystallization mold, and put them into the crystallization kiln, with the sintering temperature as 1100°, the sintering time is 2.5 hours to obtain the molten crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com