Microlite alumina ceramic belt roller barrel and processing method therefor

A fine-grained alumina, ceramic technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., to achieve the effect of easy implementation and operation, high wear resistance, high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

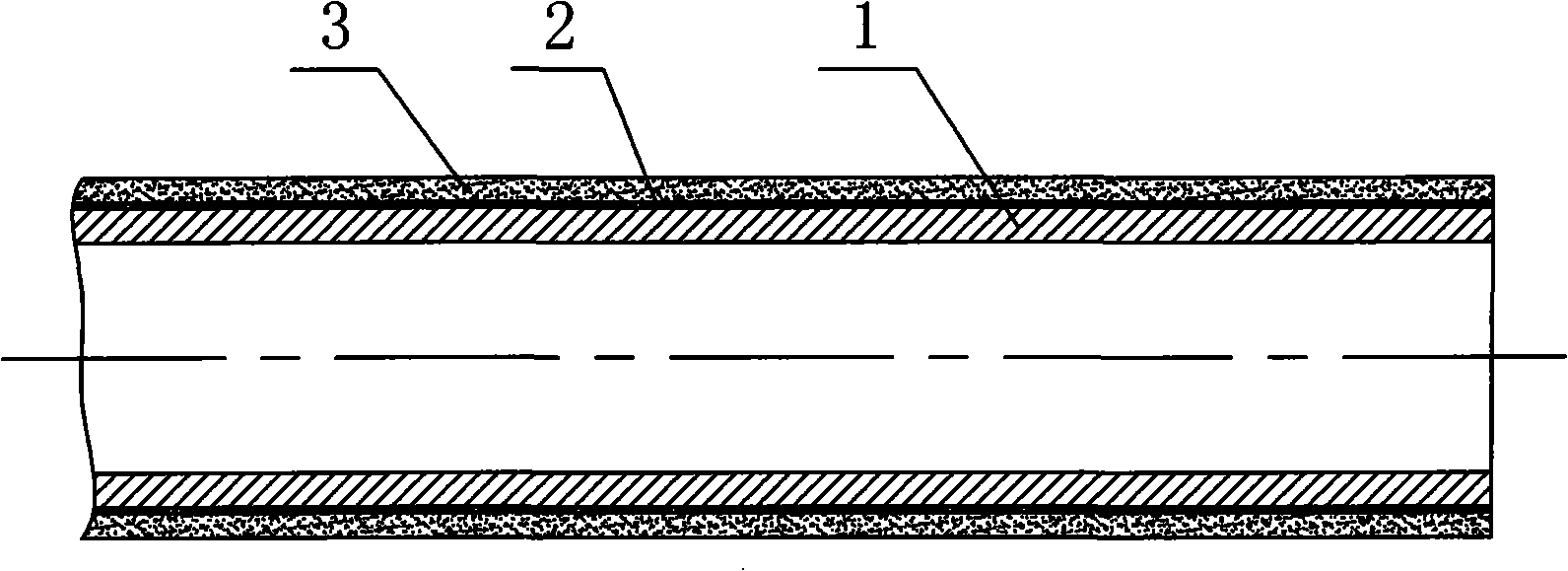

[0013] A fine-grained alumina ceramic belt idler cylinder body, which includes a steel pipe 1, a fine-grained alumina ceramic pipe 3 is fixed outside the steel pipe 1, the steel pipe 1 and the ceramic pipe 3 are coaxially installed, and the steel pipe 1 and the ceramic pipe 3 The gap between them is 1-1.6 mm, and the viscose fixing layer 2 is in the gap. The thickness of the ceramic tube 3 is 5-8 mm, and the outer diameter of the ceramic tube 3 is 80-130 mm, which can be adjusted according to user needs. The thickness of the steel pipe 1 is 2-3 mm.

Embodiment 2

[0015] A fine-grained alumina ceramic belt idler cylinder body, which includes a steel pipe 1, a fine-grained alumina ceramic pipe 3 is fixed outside the steel pipe 1, the steel pipe 1 and the ceramic pipe 3 are coaxially installed, and the steel pipe 1 and the ceramic pipe 3 The gap between them is 1.5 mm, and the adhesive fixed layer 2 is in the gap, that is, the thickness of the adhesive layer is 1.5 mm. The thickness of the ceramic tube 3 is 6mm, and the outer diameter of the ceramic tube 3 can be 89mm, 110mm, 120mm, which can be adjusted according to user needs. The thickness of the steel pipe 1 is 2-3mm, and the gap between the steel pipe 1 and the ceramic pipe 3 is 1.5mm.

Embodiment 3

[0017] A processing method for the fine-grained alumina ceramic belt idler cylinder is as follows: firstly, the outer surface of the steel pipe 1 is coated with special glue, and then the ceramic pipe 3 is set on the steel pipe 1, and the steel pipe 1 and the ceramic pipe 3 are adjusted so that the steel pipe 1 and the ceramic pipe 3 are basically Coaxial and fixed, and then cured naturally. Among them, special viscose can be purchased directly in the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com