Environmental protection type nano composite microlite

A technology of nanocomposite and microcrystalline stone, which is applied in the direction of floors, coverings/linings, buildings, etc., can solve the problems of low strength and hardness, poor fire resistance, and high cost, and achieve high surface flatness, strong environmental protection, and use safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

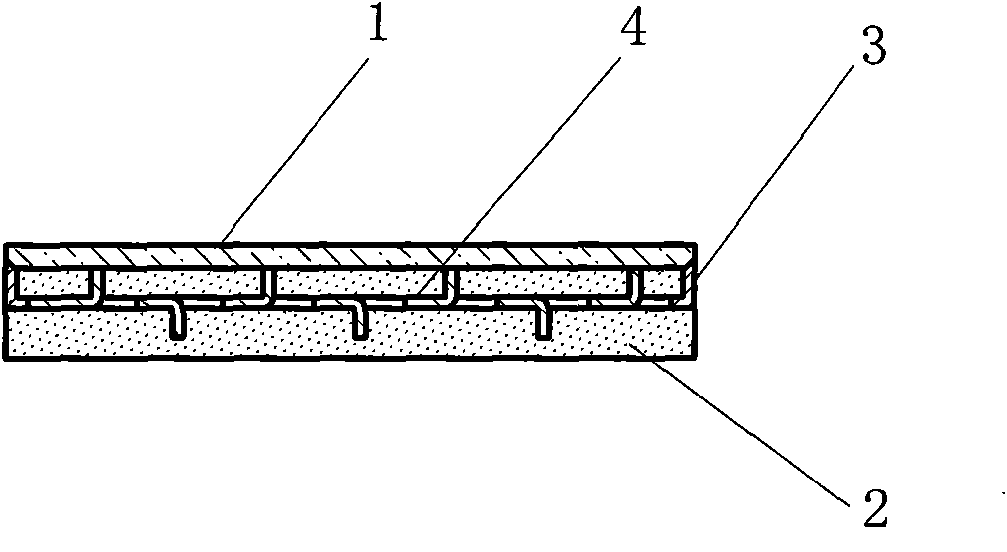

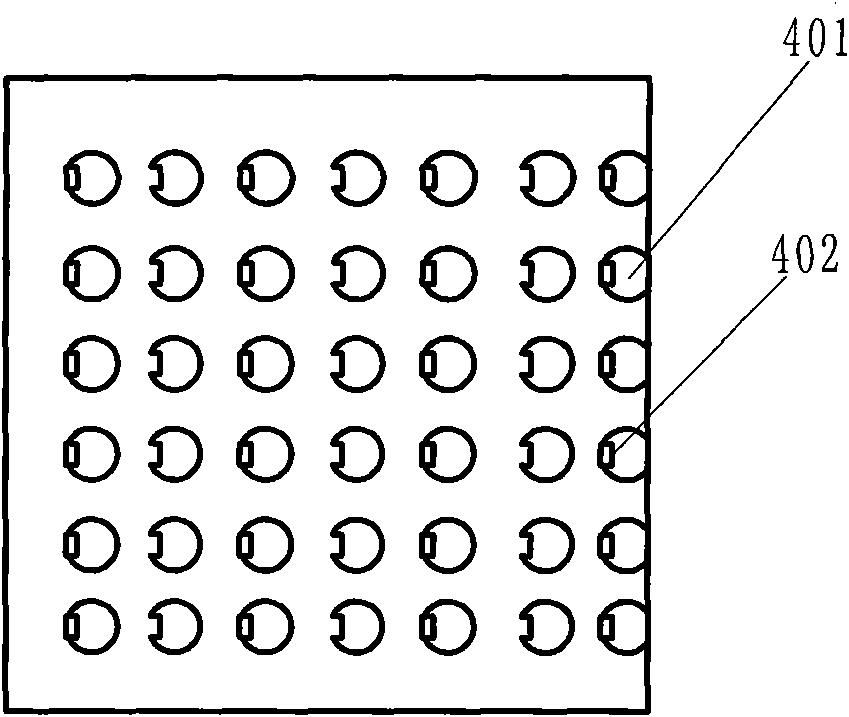

[0019] see figure 1 , figure 2 , image 3 ( figure 1 is the product profile, figure 2 It is the plan view of the enhanced flower plate), the composite microcrystalline stone of the present invention has a substrate layer 2, and the microcrystalline stone decorative layer 1 is compounded on the said substrate layer, and the enhanced flower plate 4 is arranged in the said substrate layer, and the enhanced flower plate A plurality of bonding holes 401 and a plurality of convex nails 402 are evenly distributed on the upper surface, and a metal frame 3 is set at the periphery of the composite microcrystalline stone plate, and the reinforced flower plate is connected with the metal frame; the substrate layer is made of cement and expanded perlite Composite layer, described microcrystalline stone decorative layer comprises following raw material, and the weight percent of described raw material is:

[0020] 20% resin, 4% glass particles,

[0021] Aluminum hydroxide coarse powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com