Environment-friendly type nano composite crystal agglomerated stone and production method thereof

A nano-composite and crystal-grain technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor decoration effect, little color change, easy deformation, etc., and achieve strong decoration Effect, strong decoration, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

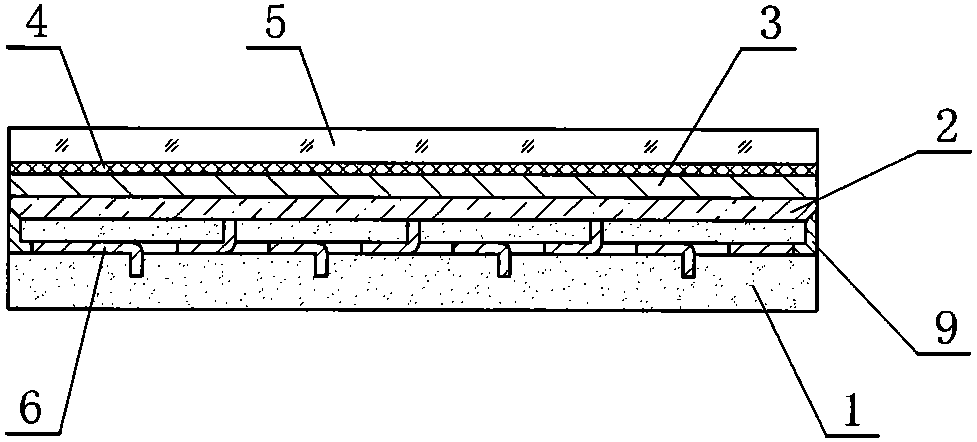

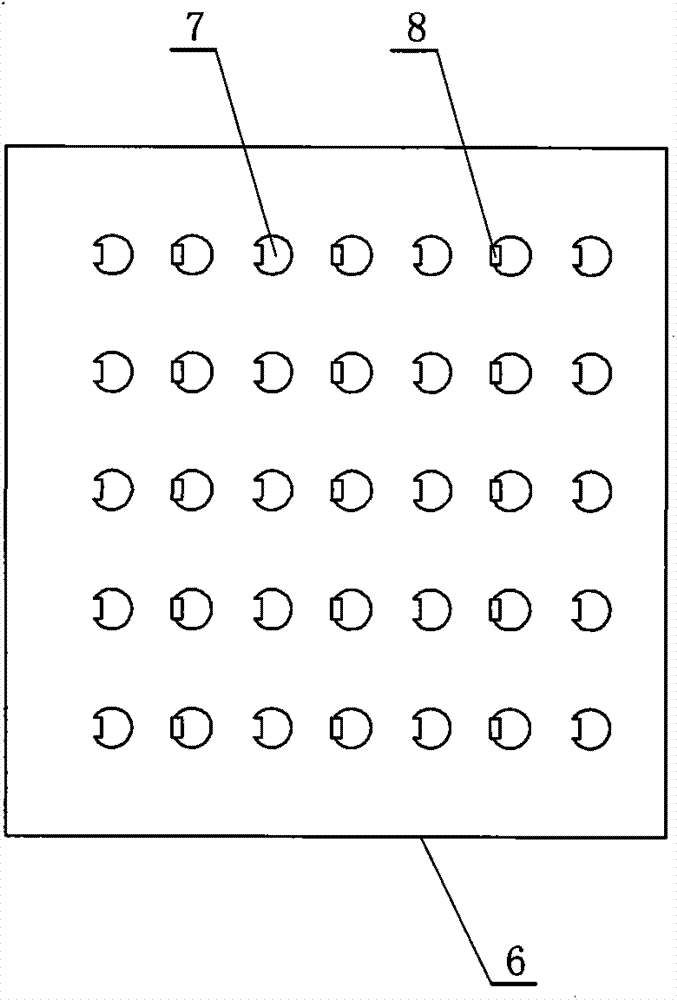

[0031] see Figure 1 to Figure 5 ( figure 1 is the product profile, figure 2 It is the plan view of reinforced flower plate), the environment-friendly nano-composite crystal granite of the present invention has a substrate layer 1, and the crystal granite plate 2 is compounded on the substrate layer, and the hollow pattern layer 3 is compounded on the crystal granite plate, so A plastic liquid crystal film 4 is arranged on the hollow pattern layer, a transparent glass plate 5 is arranged on the plastic liquid crystal film, and a thermosetting transparent glue layer is compounded between the transparent glass plate and the plastic liquid crystal film; A reinforced flower plate 6 is arranged in the substrate layer, and a plurality of joint holes 7 and a plurality of convex nails 8 are evenly distributed on the reinforced flower plate, and a metal frame 9 is arranged at the periphery of the crystal granite plate, and the reinforced flower plate and the metal The frame is conne...

Embodiment 2

[0049] This embodiment is an improvement made on the basis of Embodiment 1. For the same parts in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description is made here; the disclosure in Embodiment 1 The content should also be taken as the content disclosed in this embodiment.

[0050] In this embodiment, the transparent glass plate is a cesium potassium fireproof glass plate, and a temperature signal sensor is embedded on the inner side of the cesium potassium fireproof glass plate, and the temperature signal sensor is electrically connected to the controller.

[0051] Cesium Potassium fire-resistant glass is ion-exchanged at high temperature for more than 20 hours through special chemical treatment, replacing the sodium metal on the glass surface to form low-expansion silicate glass, which has efficient heat resistance. At the same time, after physical treatment , the surface of the glass forms a hi...

Embodiment 3

[0054] The production method of the environment-friendly nano-composite crystal granite of the present invention, the nano-composite crystal granite comprises a substrate layer, a crystal granite plate, a hollow pattern layer, a plastic liquid crystal film, a transparent glass plate, a reinforced flower plate, and a metal frame. The hollow pattern layer includes a film-coated substrate, and its production steps are as follows:

[0055] A. Use stamping equipment and molds to prepare the increased flower plate, the enhanced flower plate is a stainless steel plate with a thickness of 0.2 to 0.4 mm, or a common colored steel plate;

[0056] B. Riveting or welding the reinforced flower plate and the metal frame into one, and the metal frame is made of copper plate material;

[0057] C. Composite the substrate layer on the reinforced flower plate and the metal frame. The process of composite substrate layer adopts the existing technology and mold, and will not be described in detail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com