Comprehensive utilization method of boric sludge

A boron mud and mixture technology, applied in the field of comprehensive utilization of boron mud, can solve the problems of high energy consumption, low concentration of magnesium bicarbonate, environmental pollution, etc., and achieve the effects of unified social benefits, less cracks, and high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

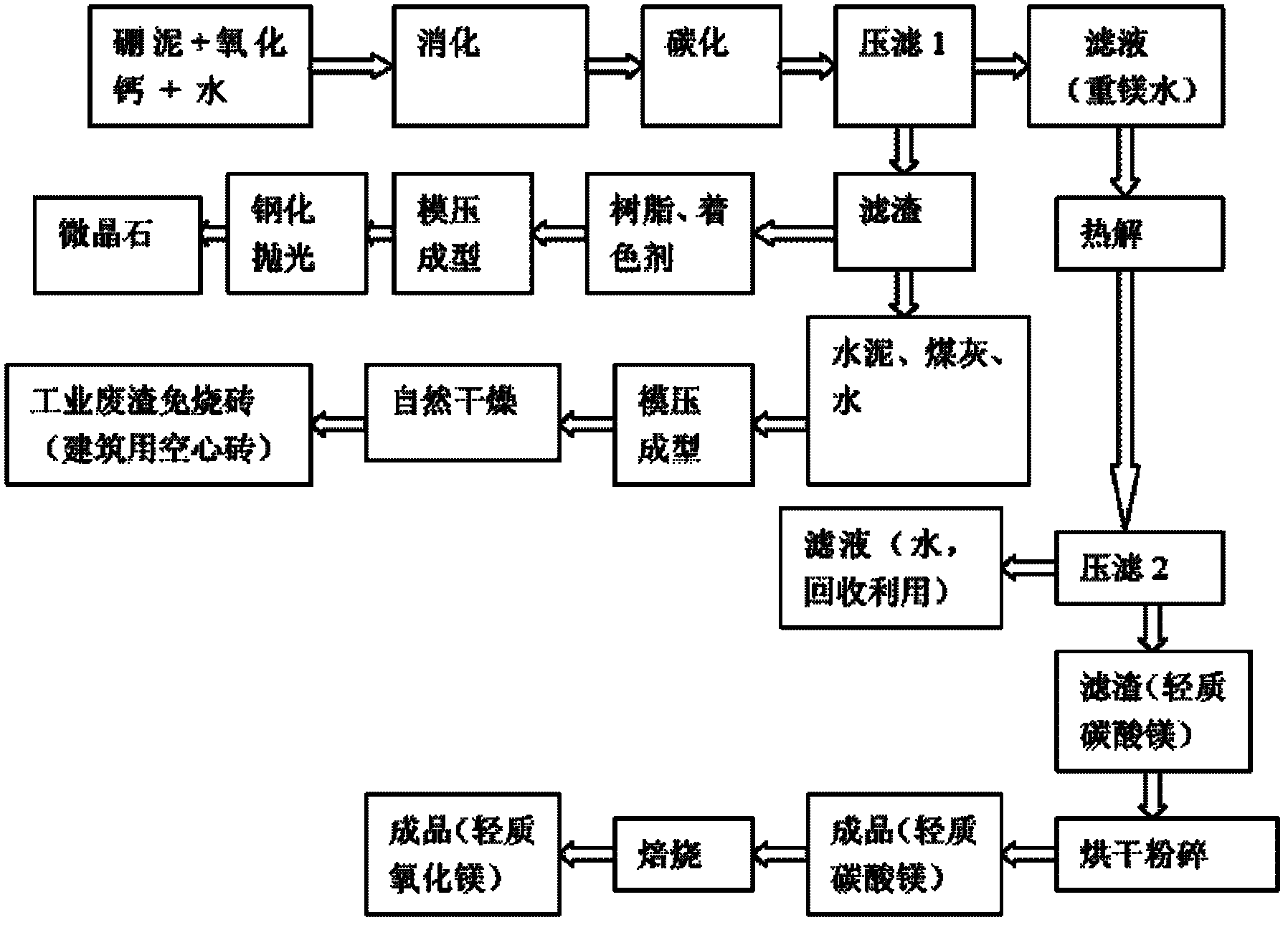

Method used

Image

Examples

Embodiment 1

[0062] 1) Stir 2000 kg of water, 1000 kg of boron mud (magnesia content is 30% by weight) and 200 kg of calcium oxide in a digestion tank, and digest at 95° C. for 150 minutes to obtain a digestion mixture.

[0063] 2) Pump the above-mentioned digestion mixture into the carbonization tank, add 8 tons of water at 25°C into the carbonization tank, and cool it at the same time to keep the carbonization temperature below 30°C. 1.5 hours.

[0064] 3) Filtrating the carbonized mixed solution to obtain magnesium bicarbonate solution and filter residue. The superheated steam of 100-120°C is passed through the magnesium bicarbonate solution for pyrolysis to obtain a precipitate of light magnesium carbonate, which is filtered, washed, dried, and then calcined at 800°C to obtain 235 kg of light magnesium oxide. The yield of the light magnesium oxide is 78%, and the quality of the product meets the "superior product" standard stipulated in the national standard (HG / T2573-1994) through th...

Embodiment 2

[0067] 1) Stir 3000 kg of water, 1000 kg of boron mud (magnesia content is 30% by weight) and 400 kg of calcium oxide in a digestion tank, and digest at 85° C. for 210 minutes to obtain a digestion mixture.

[0068] 2) Pump the above-mentioned digestion mixture into the carbonization tank, add 8 tons of water at 15°C in the carbonization tank, and cool it at the same time to keep the carbonization temperature below 30°C, and then pass in 0.2MPa carbon dioxide gas for carbonization for 2 hours. 3) Filtrating the carbonized mixed solution to obtain a magnesium bicarbonate solution. The superheated steam of 100-120°C was passed through the magnesium bicarbonate solution for pyrolysis to obtain light magnesium carbonate precipitates, which were filtered, washed, dried, and then calcined at 800°C to obtain 213 kg of light magnesium oxide. The yield of the light magnesium oxide is 71%, and the quality of the product meets the "superior product" standard stipulated in the national st...

Embodiment 3

[0071] 1) Stir 2,400 kg of water, 1,000 kg of boron mud (magnesia content is 30% by weight) and 300 kg of calcium oxide in a digestion tank, and digest at 90°C for 180 minutes to obtain a digestion mixture.

[0072] 2) Pump the above digestion mixture into the carbonization tank, add 9 tons of water at 20°C into the carbonization tank, and cool it at the same time to keep the carbonization temperature below 30°C. Add 9 kg of concentrated hydrochloric acid, pass through 0.3MPa carbon dioxide gas, and carbonize for 1.5 hours.

[0073] 3) Filtrating the carbonized mixed solution to obtain a magnesium bicarbonate solution. The superheated steam of 100-120°C is passed through the magnesium bicarbonate solution for pyrolysis to obtain a precipitate of light magnesium carbonate, which is filtered, washed, dried, and then calcined at 800°C to obtain 210 kg of light magnesium oxide. The yield of the light magnesium oxide is 70%, and the quality of the product meets the "superior produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com