Waterproof and fire-retardant floor and manufacturing method thereof

A floor and substrate technology, applied in layered products, floors, buildings, etc., can solve the problems of easy slipping, stiff feet, cracking, etc., and achieve the effect of not easy to slip and feel jerky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

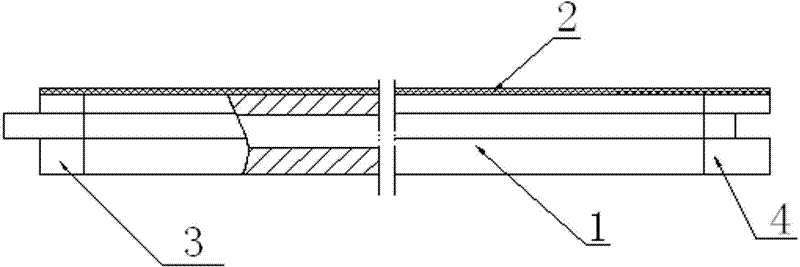

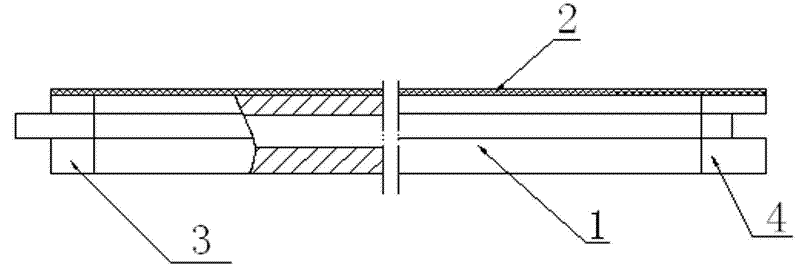

[0022] figure 1 A method of making the waterproof and flame-retardant floor shown is as follows:

[0023] (1) Preparation of chemical raw materials: by weight percentage, 36% of dioctyl ester, 5% of stearic acid, 7% of paraffin, 16% of chlorinated polyethylene, 36% of dust-free composite lead salt stabilizer Mix with each other to obtain chemical raw materials;

[0024] (2) According to weight percentage, mix 25% PVC, 35% wood powder, and 35% microcrystalline stone powder, mix evenly, and dry; then, add 5% chemical raw materials according to weight percentage, and stir evenly ;

[0025] (3) Granulation: granulation at a temperature of 170-180°C;

[0026] (4) Configure a forming die on the extruder, heat extrusion molding at a temperature of 160-180 ° C, cool with water, and then cut according to the length dimension to obtain a matrix with hollow holes along the length direction;

[0027] (5) Both ends of the base body along the length direction are blocked by plugs, one e...

Embodiment 2

[0030] figure 1 A method of making the waterproof and flame-retardant floor shown is as follows:

[0031] (1) Preparation of chemical raw materials: 35% dioctyl ester, 6% stearic acid, 6% paraffin, 15% chlorinated polyethylene, 38% dust-free composite lead salt stabilizer Mix with each other to obtain chemical raw materials;

[0032] (2) Mix 25% PVC, 33% wood powder and 37% microcrystalline stone powder according to the weight percentage, and then dry them; then, add 5% chemical raw materials according to the weight percentage, and stir evenly ;

[0033] (3) Granulation: granulation at a temperature of 170-180°C;

[0034] (4) Configure a forming die on the extruder, heat extrusion molding at a temperature of 160-180 ° C, cool with water, and then cut according to the length dimension to obtain a matrix with hollow holes along the length direction;

[0035] (5) Both ends of the base body along the length direction are blocked by plugs, one end of the plug is processed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com