Permeable brick and its preparation method

A technology of permeable bricks and permeable coefficient, which is applied to pavements, roads, pavements and other directions paved with prefabricated blocks. , the effect of a simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

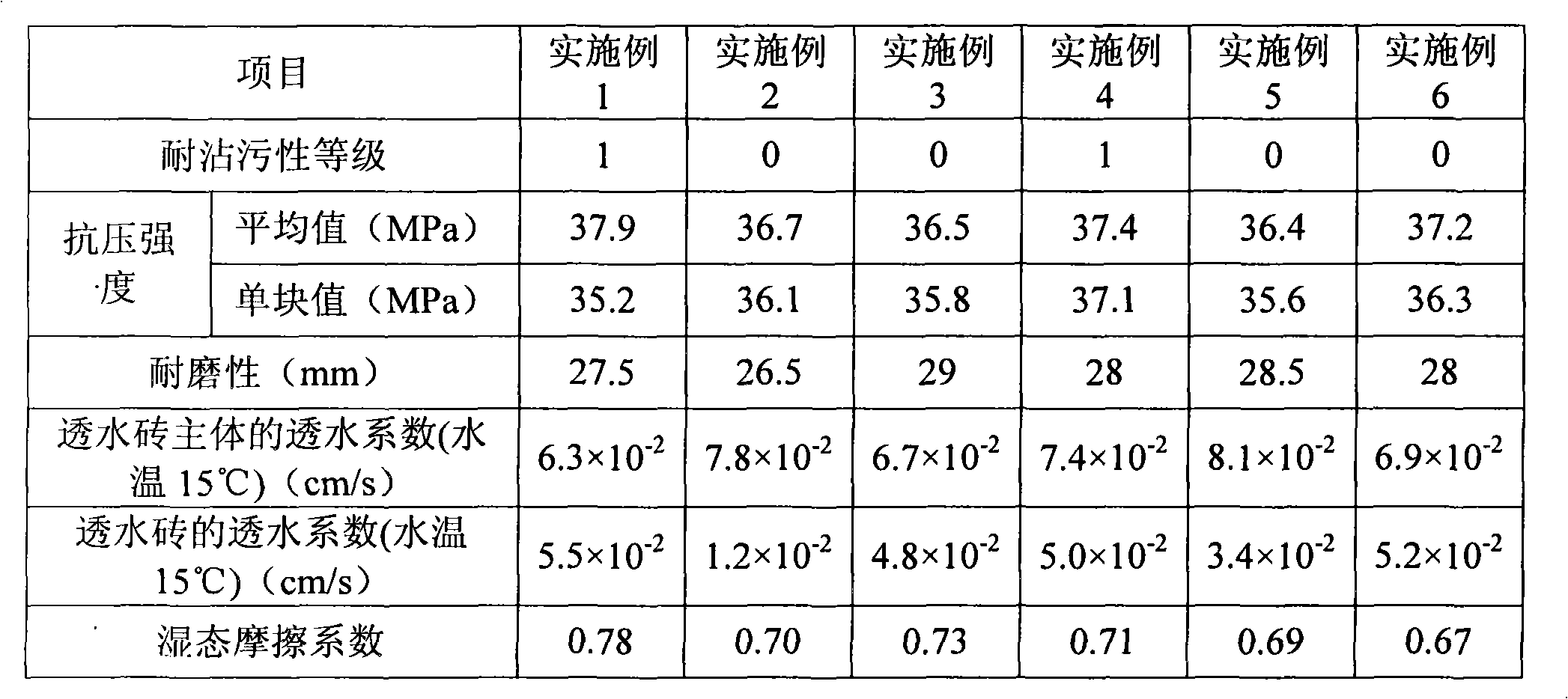

Embodiment 1

[0034] 100 grams of quartz sand with a particle diameter of 0.1-0.25 mm, 4.6 grams of hydrogenated bisphenol A epoxy resin (purchased from Wuhan Shizishan Paint Factory), 1.4 grams of aliphatic polyamine curing agent (purchased from Yuanhong) Applied Materials Co., Ltd., model H-3528), 0.12 grams of γ-glycidoxypropoxypropyltrimethoxysilane (purchased from Beijing Shenda Fine Chemical Co., Ltd., model A-187), After mixing 0.012 g of light stabilizer UV-320 and 0.006 g of antioxidant 1010, 1 g of perlite powder and 3 g of alcohol, they are filled into the mold to form a permeable surface layer;

[0035] 100 grams of quartz sand with a particle diameter of 0.2-0.5 mm, 3.8 grams of hydrogenated bisphenol A epoxy resin (purchased from Wuhan Shizishan Paint Factory), 1.2 grams of aliphatic polyamine curing agent (purchased from Yuanhong Applied Materials Co., Ltd., model H-3528), 0.1 g of glycidoxypropyltrimethoxysilane (purchased from Beijing Shenda Fine Chemical Co., Ltd., model A-18...

Embodiment 2

[0038] The water-permeable brick body was prepared according to the method of Example 1, except that the quartz sand of the water-permeable surface layer was replaced by quartz sand with a particle diameter of 0.4-0.8 mm to make the water-permeable brick body.

[0039] On the surface of the main body of the prepared permeable brick, with 350g / m 2 Spray the water-based fluorocarbon paint (Beijing Zhitu Chemical, water-based fluorocarbon emulsion ZT-302) with the amount used, and then dry it at 80°C for 6 hours to make permeable bricks. After calculating the adhesion amount of the stain-resistant coating layer of the permeable brick is 200g / m 2 .

Embodiment 3

[0041] The water-permeable brick body was prepared according to the method of Example 1, except that the quartz sand of the water-permeable surface layer was replaced by quartz sand with a particle diameter of 0.2-0.45 mm to make the water-permeable brick body.

[0042] On the surface of the main body of the prepared permeable bricks, 193g / m 2 Spray the solvent-based fluorocarbon liquid (Beijing Beimu New Material, 881-Y11 fluorocarbon paint) with the amount used, and then dry it at 60°C for 4 hours to make permeable bricks. After calculation, the adhesion amount of the stain-resistant coating layer of the permeable brick is 110g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com