1000MPa-level automobile steel with high product of strength and elongation and manufacturing method thereof

A technology of high-strength plastic product and manufacturing method, which is applied to high-strength plastic-product automotive steel and its manufacturing field of 1000 MPa level, can solve the problems such as the inability to realize continuous annealing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

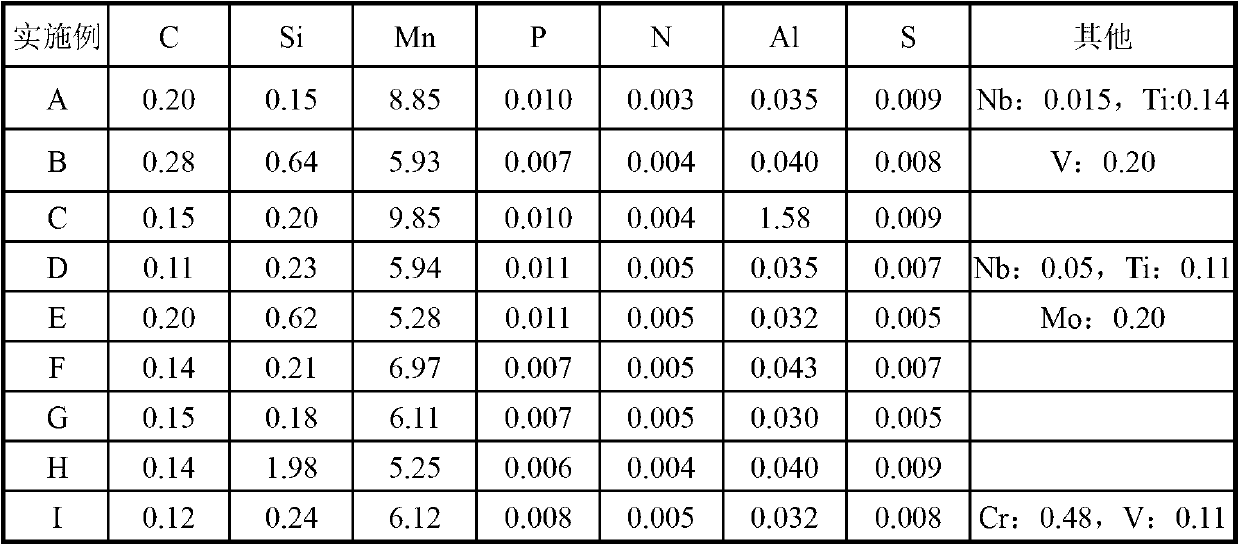

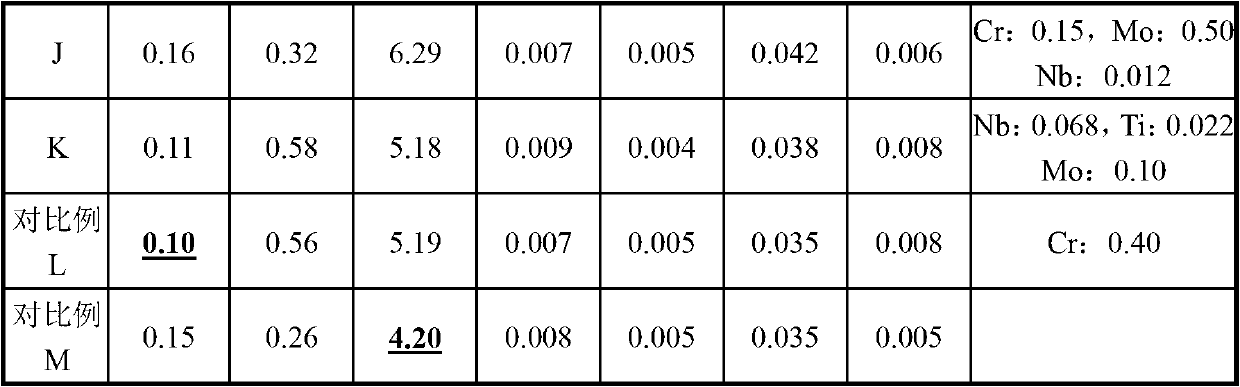

[0031] Manufacture the high-strength plastic product automobile steel of the present invention according to the following steps:

[0032] (1) Smelting the chemical elements in the ratio shown in Table 1, using a converter (electric furnace or induction furnace can also be used for smelting);

[0033] (2) Continuous casting to produce slabs;

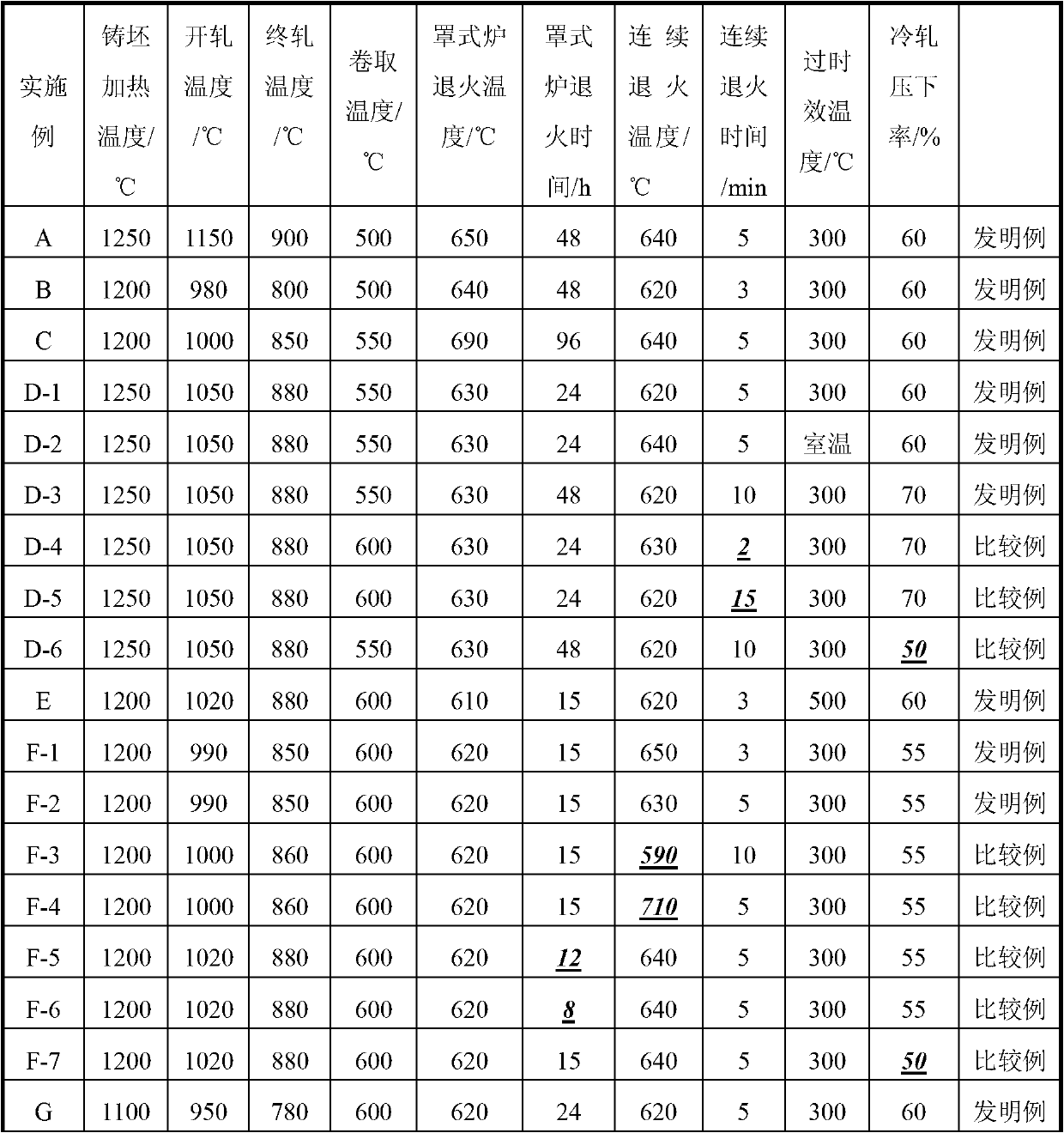

[0034] (3) Hot rolling: heating the slab to 1100~1250°C and then controlling rolling, the starting rolling temperature is 950~1150°C, the final rolling temperature is 750~900°C, and the thickness of the hot rolled plate is not more than 8mm;

[0035] (4) Coil at 500~700°C after rolling, and the structure is full martensite after cooling to room temperature;

[0036] (5) Pickling to remove iron oxide scale generated during hot rolling;

[0037] (6) Bell furnace annealing: the annealing temperature is 600~700°C, between Ac1 and Ac3 temperatures, the annealing time is not less than 15 hours, and part of the austenite structure is obtained af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com