Online comprehensive control method for hot-galvanized continuous annealing furnace

A continuous annealing furnace and comprehensive control technology, applied in heat treatment furnaces, adaptive control, general control systems, etc., can solve the problems of lack of overall control methods, lack of mathematical models and theoretical foundations, and achieve convenient model construction and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0041] The vertical hot-dip galvanizing continuous annealing furnace is composed of a preheating section, a heating section, a soaking section, a rapid cooling section and an equalizing section. Both the preheating section and the fast cooling section heat and cool the steel strip through the circulation fan, the heating section and the soaking section are controlled by the power of the radiant tube, and the equalization section is carried out by natural cooling and part of the radiant tube. Temperature outlet control to keep the strip outlet temperature meeting the temperature requirements of galvanizing.

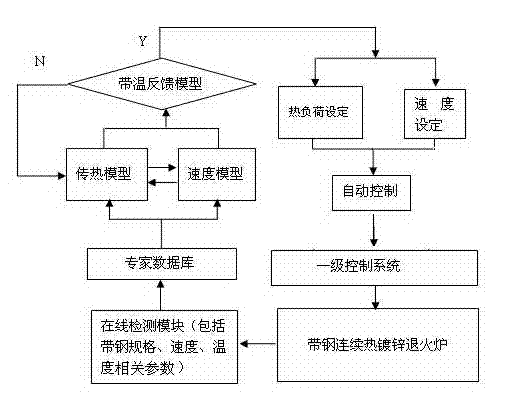

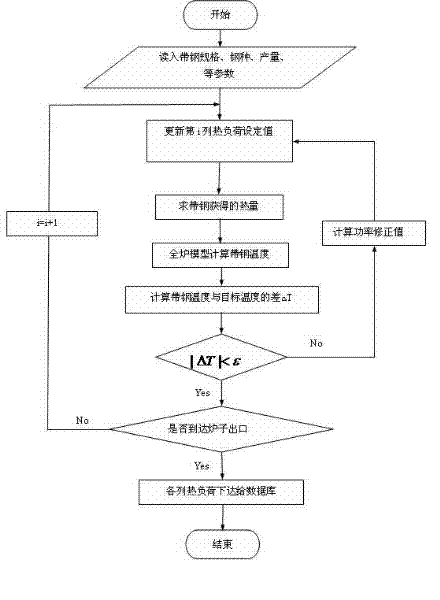

[0042] like figure 1 Shown, method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com