Multilayer type electromagnetic wave absorber and manufacturing method thereof

An absorber, electromagnetic wave technology, applied in the direction of magnetic objects, chemical instruments and methods, circuits, etc., can solve the problems of limited wave absorption performance, poor flexibility, unsuitable for high hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

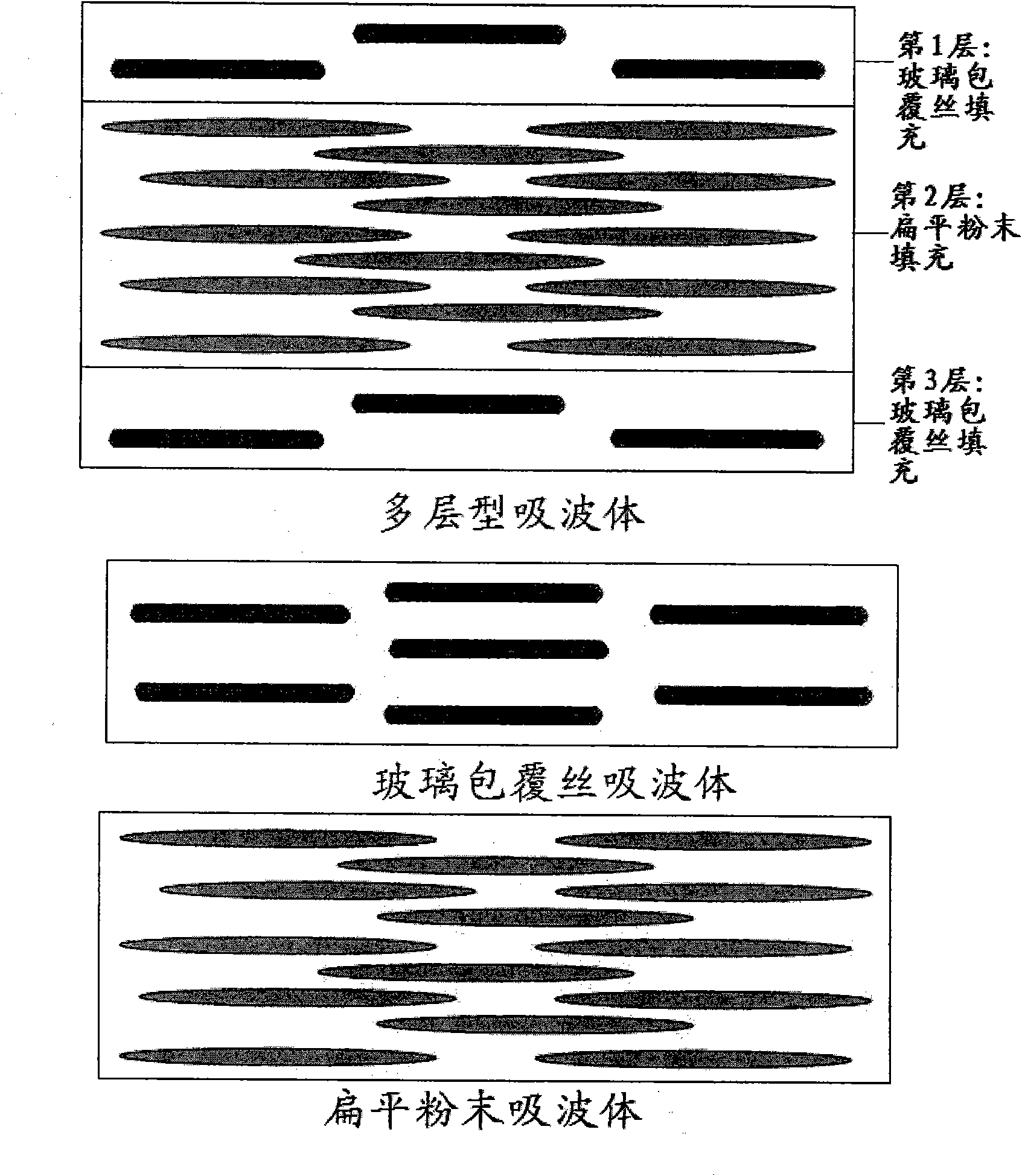

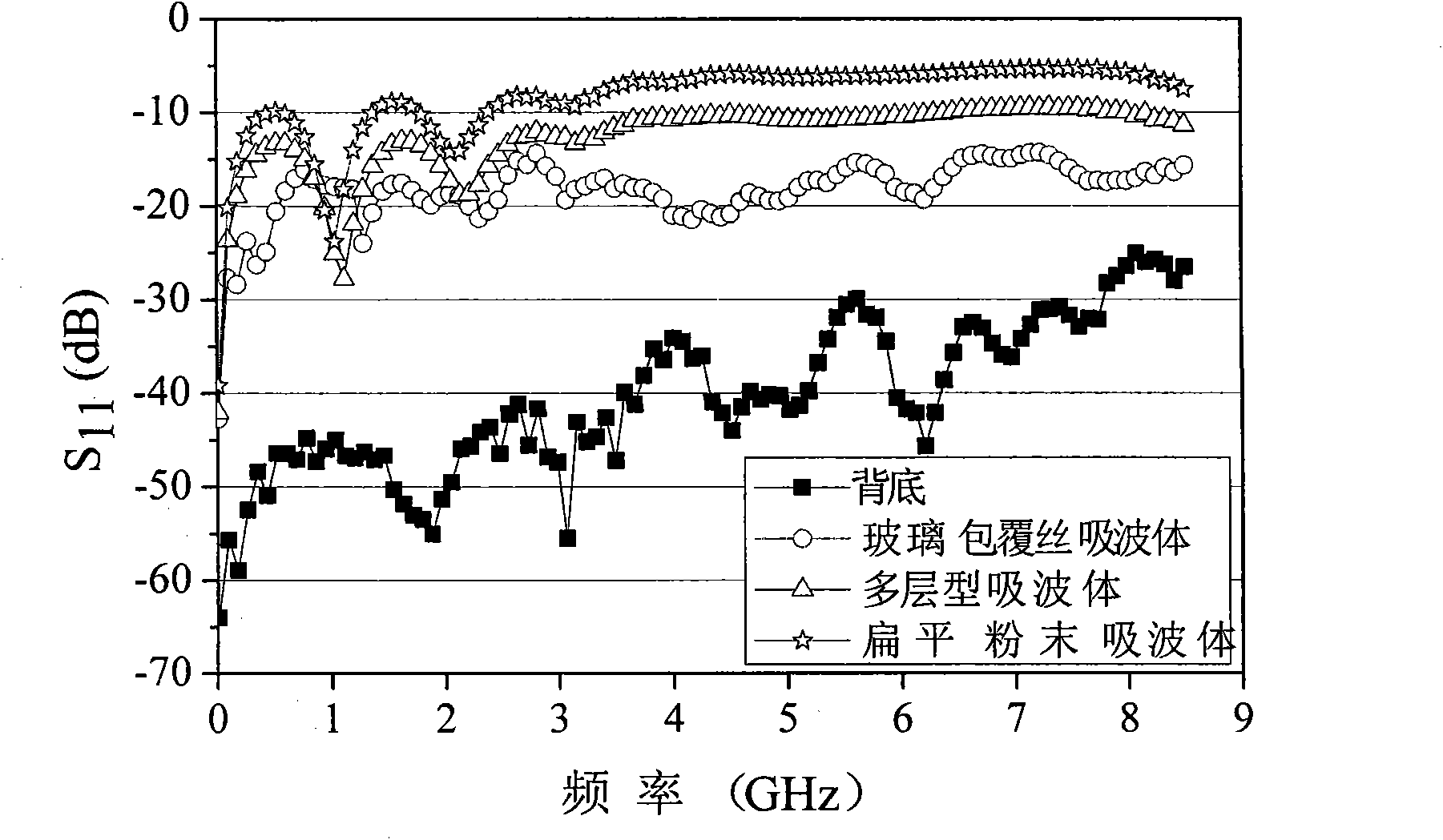

[0052] Preparation of multi-layer absorber

[0053] Then the glass-coated silk absorber is used as the surface layer of the multi-layer absorber, and the flat amorphous alloy powder absorber is used as the middle layer, and the glass-coated silk absorber and the flat amorphous alloy powder absorber are obtained by lamination. Multi-layer absorber composed of crystal alloy powder absorber.

[0054] When the electromagnetic wave is incident on the multi-layer absorber, the surface layer absorbs part of the electromagnetic wave first, and because of its low reflection coefficient, it can continue to transmit most of the unabsorbed electromagnetic wave to the middle layer, thereby continuing to produce the absorbing effect. When the electromagnetic wave is reflected from the surface of the intermediate layer, it passes through the glass-coated silk layer again, so that further electromagnetic wave absorption occurs. In this way, the incident electromagnetic waves are mostly absor...

Embodiment 1

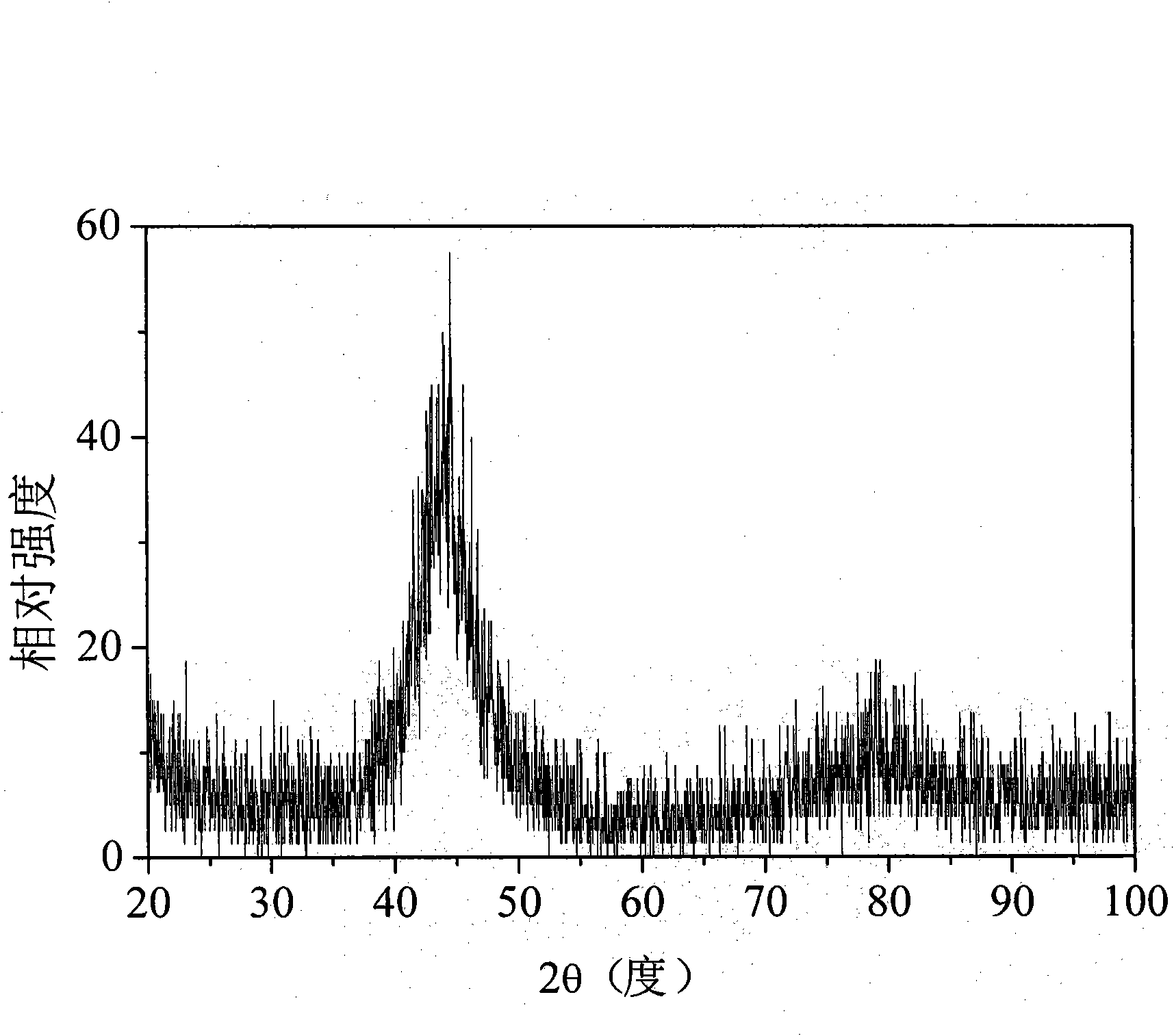

[0060] Preparation of Fe by Water Atomization 74 Cr 2 Mo 2 sn 2 P 8 Si 6 B 4 C 2 Soft magnetic powder, whose X-ray diffraction results show that it is an amorphous structure, such as figure 1 shown. Among them, the process of preparing amorphous alloy powder by water atomization method is as follows: use 5 atmospheres of high-pressure water to crush the metal droplets and quickly cool them, and dry the atomized products in a vacuum oven at 180 ° C for 8 hours , and sieve the dried product to obtain 200-325 mesh near-spherical amorphous alloy powder.

[0061] The obtained nearly spherical amorphous alloy powder was subjected to wet ball milling in a planetary ball mill with a ball-to-material ratio of 4:1 and a rotational speed of 400 rpm, adding absolute ethanol as a dispersion medium. After ball milling for 12 h, the nearly spherical amorphous powder was flattened into a flat powder with an average thickness of 1 μm and an average diameter of 50 μm. Subsequently, th...

Embodiment 2

[0074] The flat amorphous alloy powder of this embodiment adopts iron-based amorphous alloys of different compositions, and is prepared into powder by the same atomization method as in Embodiment 1. Alloy compositions are Fe 72 Cr 1 Mo 1 sn 2 P 15 Si 1 B 7.5 C 0.5 , Fe 72 Cr 5 Mo 3 sn 2 P 3 Si 2 B 12 C 1 , Fe 72 Cr 1 Mo 1 sn 3 P 8 Si 8 B 1 C 6 , Fe 73 Cr 2 Nb 5 sn 2 P 2 Si 8 B 6 C 2 , Fe 74 Cr 2 Mo 2 sn 2 P 10 Si 4 B 4 C 2 , Fe 76 Cr 1 Mo 1 Al 4 P 8 Si 8 B 1 C 1 , Fe 78 Cr 1 Mo 1 sn 2 P 8 Si 8 B 1 C 1 . The atomized powder was wet-milled in a planetary ball mill with a ball-to-material ratio of 5:1, a rotational speed of 400 rpm, and a milling time of 14 hours. Subsequently, the powder is heat-treated in a vacuum heat treatment, and the process parameter is 420° C. for 1 hour.

[0075] The thermoplastic polyurethane was dissolved by nitrogen methyl formamide as an organic solvent to prepare a coating with a thermoplastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com