Preparation method of reactive polyurethane hot melt adhesive for fabric lamination

A polyurethane hot-melt adhesive, reactive technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems affecting the promotion of novel and changeable fabrics, garment production, and narrow fabric selectivity. To achieve the effect of excellent resistance to enzymes, not easy to change color and deterioration, and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

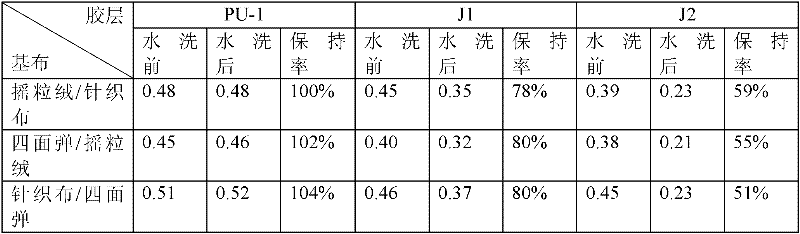

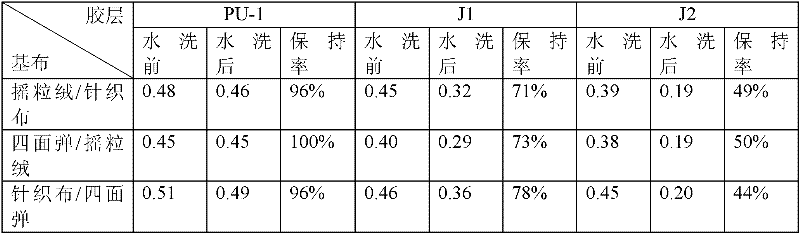

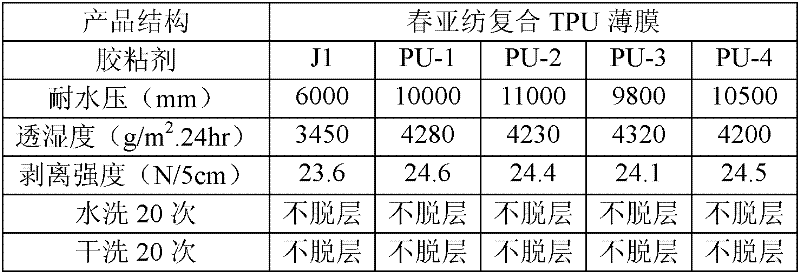

Examples

Embodiment 1

[0018] a. Weigh 51g of polyether polyol polyoxypropylene diol, 10g of polyester polyol polyhexamethylene adipate diol, 4g of chain extender 1,4 butanediol, adhesion promoter E-51 ring Add 2g of oxygen resin and 0.1g of antioxidant CHINOX1010 into a three-necked flask, heat and stir to mix, vacuum dry and dehydrate at 110°C to 140°C for 2.5h, and cool down to 65°C;

[0019] b. Add 32 g of diphenylmethane-4,4 diisocyanate, 3 drops of stannous octoate catalyst, 1 g of γ-aminopropyltriethoxysilane KH550 silane coupling agent to the above mixture under nitrogen protection, and react for 20 to 30 minutes Finally, discharge the material and seal the package, and put it into an oven at 80°C for curing for 6 to 8 hours to obtain the reactive polyurethane hot-melt adhesive for fabric compounding, and the serial number is PU-1.

Embodiment 2

[0021] a. Weigh 40g of polyether polyol PEG, 5g of polyester polyol polyhexamethylene adipate diol, 1g of chain extender trimethylol propane, 2g of 1,4 butanediol, adhesion promoter E Add 1g of -44 epoxy resin and 0.1g of light stabilizer UV-320 into a three-necked flask, heat and stir at 110°C to 140°C to mix, vacuum dry and dehydrate at 110°C to 140°C for 2.5h, and cool to 75°C to obtain reaction mixture;

[0022] b. Add 25g of diphenylmethane-4,4 diisocyanate, 4 drops of catalyst dibutyltin dilaurate, silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane KH-560 0.5 to the above mixture under nitrogen protection g. After reacting for 20 minutes, discharge and seal the package, put it in an oven at 80°C for 8 hours, and then get the reactive polyurethane hot-melt adhesive for fabric lamination, coded as PU-2.

Embodiment 3

[0024] a. Weigh 55g of polytetrahydrofuran diol, 8g of polyester polyol polyε-caprolactone polyol, 1g of chain extender trimethylolpropane, 1g of 1,4 butanediol, adhesion promoter bisphenol A ring Add 2g of epoxy resin, 0.05g of antioxidant CHINOX1010 and 0.05g of light stabilizer UV-320 into a three-necked flask, heat and stir to mix, vacuum dry and dehydrate at 110°C for 2.5h, cool down to 65-75°C to obtain a reaction mixture;

[0025] b. Under the protection of nitrogen, add 32 g of diphenylmethane-4,4 diisocyanate, 3 drops of catalyst bismorpholino diethyl ether, and 1 g of silane coupling agent γ-aminopropyltrimethoxysilane KH-551 into the above mixture , after reacting for 20 minutes, discharge the material and seal the package, put it in an oven at 80°C for 7 hours, and then get the reactive polyurethane hot melt adhesive for fabric compounding, which is coded as PU-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com