Hot-melting optical adhesive film for 3D curved display and preparation method thereof

A technology of hot-melt adhesive film and optical adhesive, which is applied in the field of optical adhesive and can solve the problems of low initial viscosity, air bubbles, displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

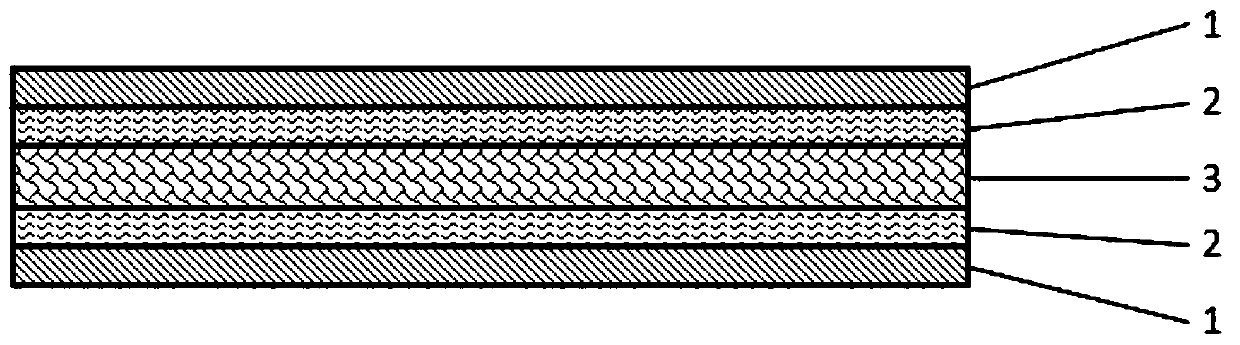

Image

Examples

Embodiment 1

[0032] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0033] The optical adhesive pre-coating solution is coated on a layer of release film (the release film is a commonly used release film in the art) by a coating machine, the coating thickness is 0.05mm, and UV curing is carried out to form a pressure-sensitive optical film. Glue-coated OCA;

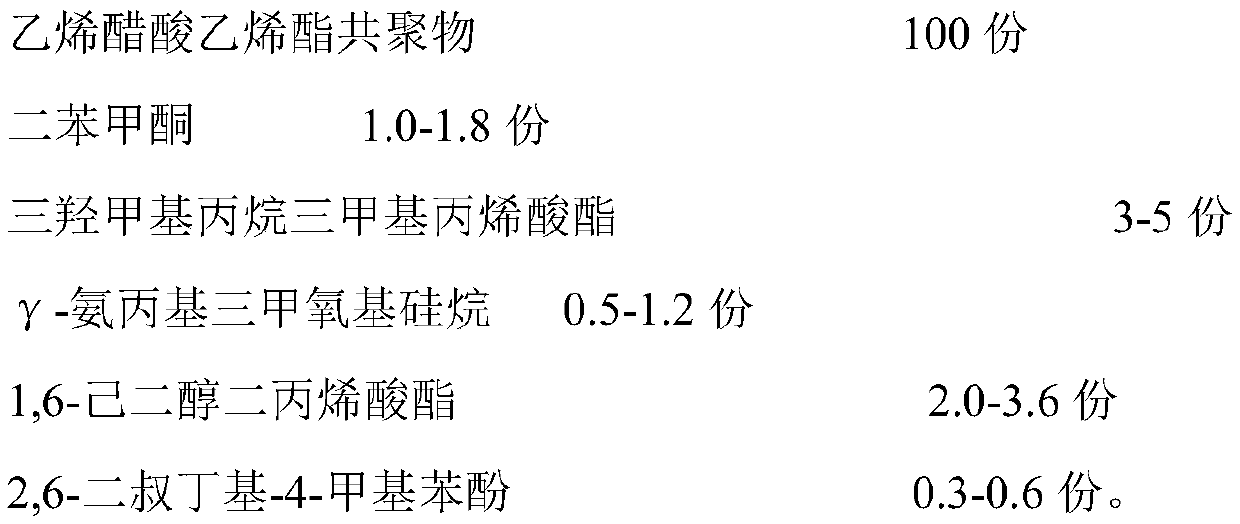

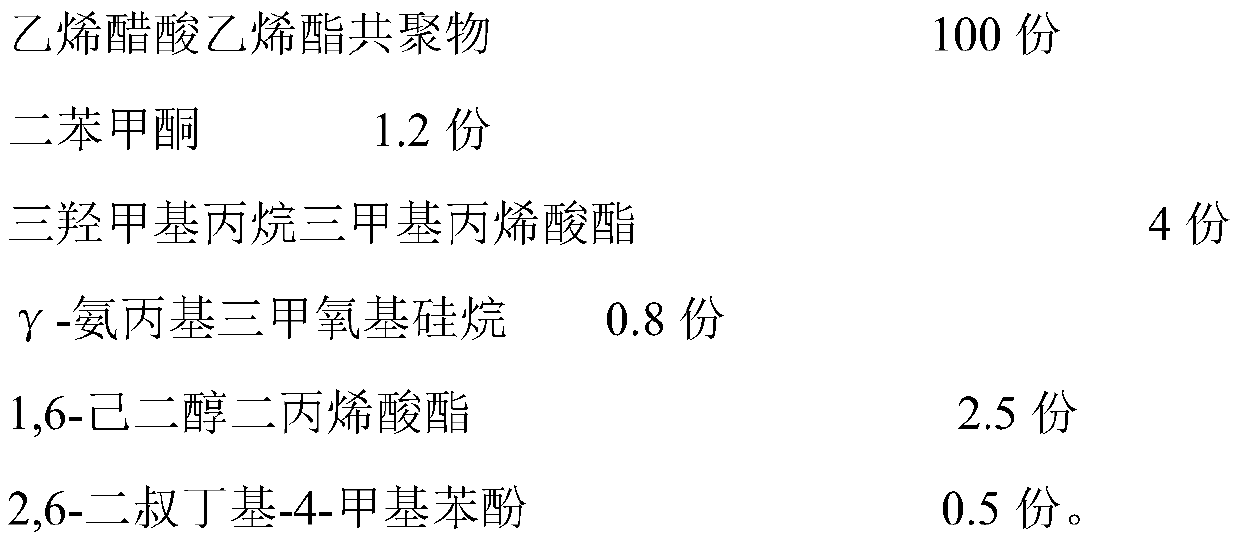

[0034] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylate, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly by a high-speed mixer at 300 rpm, and fully dried at 40°C for 2 hours to form a hot-melt optical adhesive HCA premix.

[0035] Put the hot-melt optical adhesive HCA premix into the hopper of the casting ...

Embodiment 2

[0037] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0038] The optical adhesive pre-coating solution is coated on a layer of release film through a coating machine, the coating thickness is 0.1mm, and it is cured by UV to form a pressure-sensitive optical adhesive coating OCA;

[0039] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylic esters, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly by a high-speed mixer at a speed of 300 rpm, and fully dried at 40°C for 2 hours to learn glue HCA premix.

[0040] Put the hot-melt optical adhesive HCA premix into the hopper of the casting machine, melt it at 110°C, plasticize and extrude it, and laminate it wi...

Embodiment 3

[0042] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0043] The optical adhesive pre-coating solution is coated on a layer of release film by a coating machine, the coating thickness is 0.15mm, and it is cured by UV to form a pressure-sensitive optical adhesive coating OCA;

[0044] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylic ester, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly with a high-speed mixer at a speed of 300 rpm, and fully dried at 40°C for 2 hours to form a hot-melt optical adhesive HCA premix.

[0045] Put the hot-melt optical adhesive HCA premix into the hopper of the casting machine, melt it at 110°C, plasticize and extrude it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com