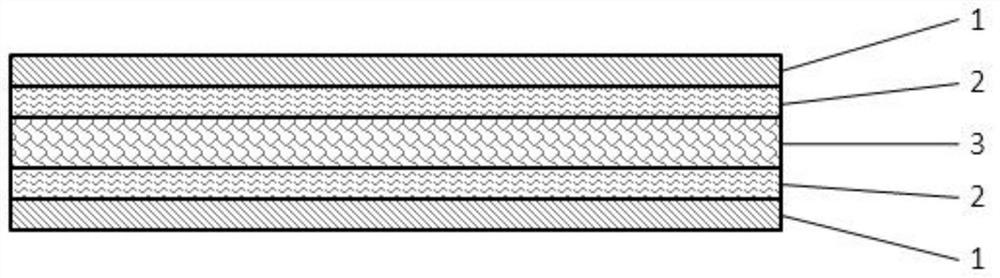

A kind of 3D curved screen hot-melt optical adhesive film and preparation method thereof

A hot-melt adhesive film and optical adhesive technology, applied in the field of optical adhesive, can solve the problems of low initial viscosity, air bubbles, displacement, etc., and achieve the effect of good initial viscosity and easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0033] The optical adhesive pre-coating solution is coated on a layer of release film (the release film is a commonly used release film in the art) by a coating machine, the coating thickness is 0.05mm, and UV curing is carried out to form a pressure-sensitive optical film. Glue-coated OCA;

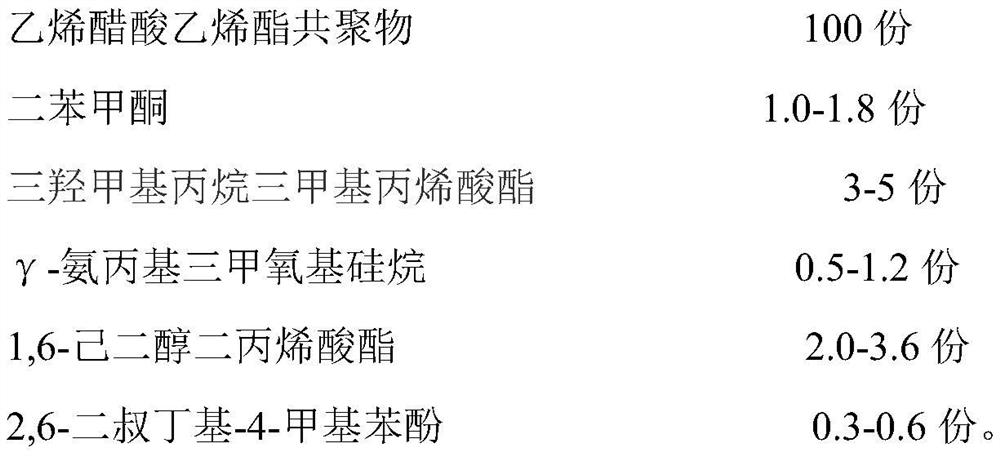

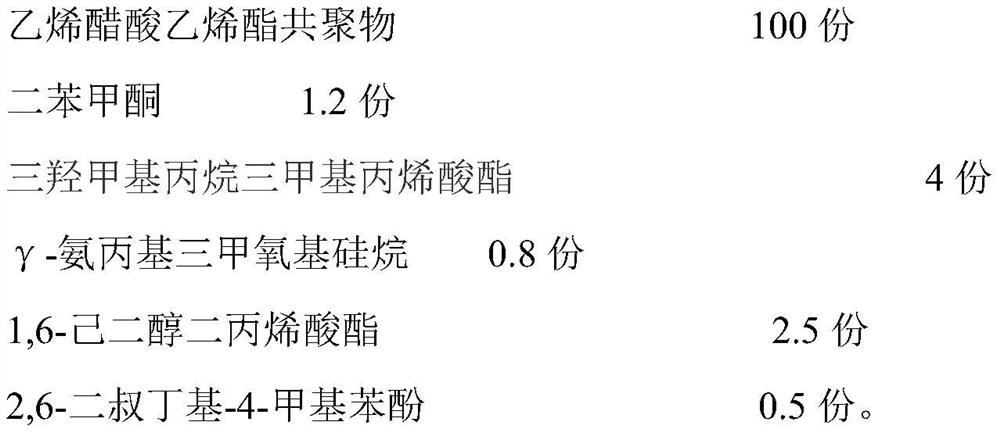

[0034] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylate, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly by a high-speed mixer at 300 rpm, and fully dried at 40°C for 2 hours to form a hot-melt optical adhesive HCA premix.

[0035] Put the hot-melt optical adhesive HCA premix into the hopper of the casting ...

Embodiment 2

[0037] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0038] The optical adhesive pre-coating solution is coated on a layer of release film through a coating machine, the coating thickness is 0.1mm, and it is cured by UV to form a pressure-sensitive optical adhesive coating OCA;

[0039] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylic esters, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly by a high-speed mixer at a speed of 300 rpm, and fully dried at 40°C for 2 hours to learn glue HCA premix.

[0040] Put the hot-melt optical adhesive HCA premix into the hopper of the casting machine, melt it at 110°C, plasticize and extrude it, and laminate it wi...

Embodiment 3

[0042] Add 45g of pentaerythritol triacrylate, 1.5g of 1-hydroxycyclohexyl phenyl ketone, 0.5g of 2,6-di-tert-butyl-4-methylphenol, 1g of toluene diisocyanate to 55g of urethane acrylate prepolymer, and mix Stir to form optical glue precoating solution;

[0043] The optical adhesive pre-coating solution is coated on a layer of release film by a coating machine, the coating thickness is 0.15mm, and it is cured by UV to form a pressure-sensitive optical adhesive coating OCA;

[0044] Add 1.2g benzophenone, 4g trimethylolpropane trimethacrylate, 0.8g γ-aminopropyltrimethoxysilane, 2.5g 1,6-hexanediol diol to 100g ethylene-vinyl acetate copolymer Acrylic ester, 0.5g of 2,6-di-tert-butyl-4-methylphenol, mixed evenly with a high-speed mixer at a speed of 300 rpm, and fully dried at 40°C for 2 hours to form a hot-melt optical adhesive HCA premix.

[0045] Put the hot-melt optical adhesive HCA premix into the hopper of the casting machine, melt it at 110°C, plasticize and extrude it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com