LED light source for backlighting with integrated electronics

A light-emitting diode and backlight technology, applied in the field of white light backlight, can solve the problems that printed circuit boards cannot be completely suppressed, expensive, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

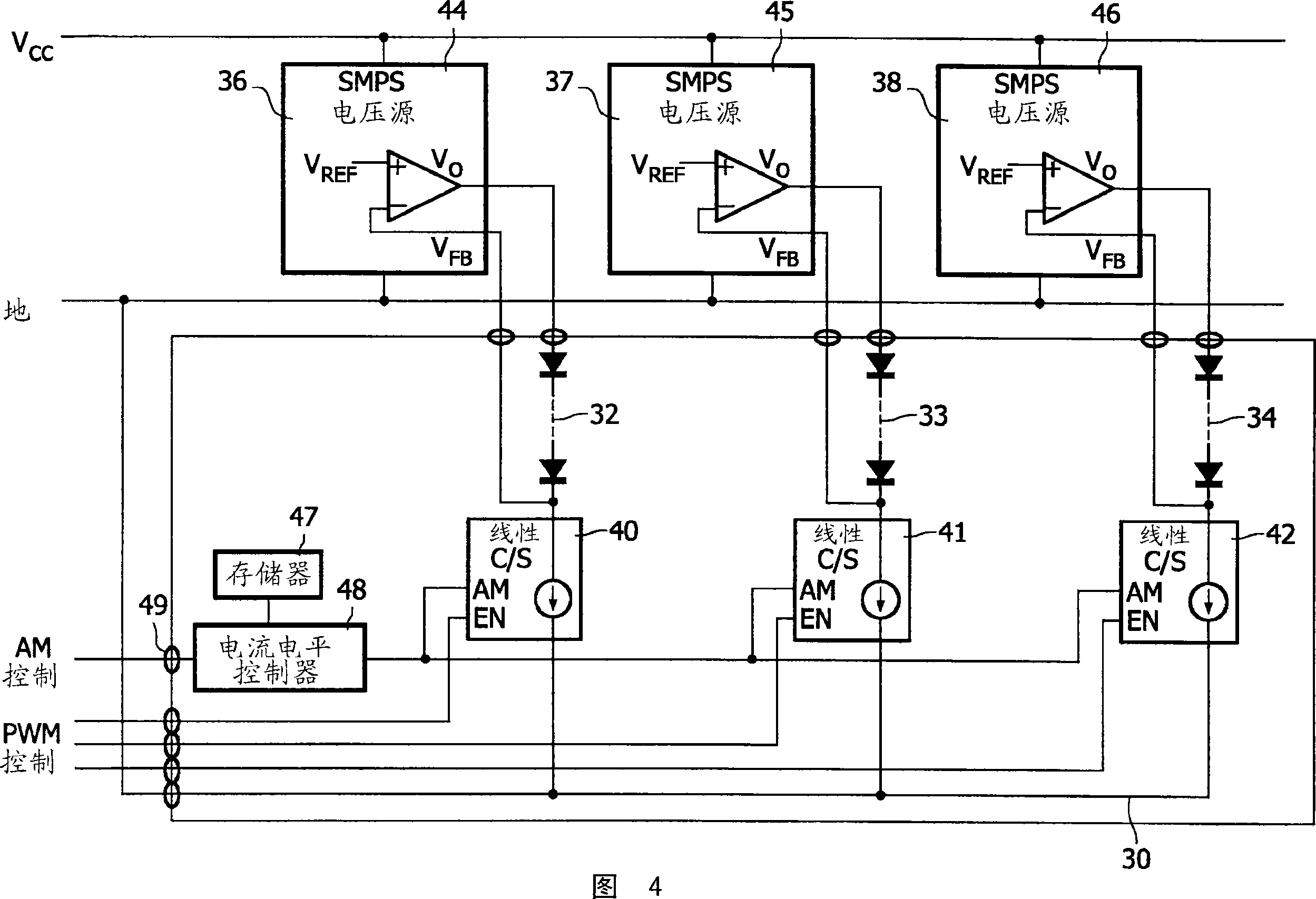

[0035] Figure 4 shows the electronics and light sources of a backlight printed circuit board for a liquid crystal display. In one embodiment, the light emitting diodes and current source are mounted on a single printed circuit board (PCB) 30 . In another embodiment, the voltage regulator is also mounted on the printed circuit board 30 .

[0036]A series string of red LEDs 32 , green LEDs 33 and blue LEDs 34 is shown. By adjusting the current through the red, green and blue LEDs, any white point can be achieved by the backlight.

[0037] The anode of each string is connected to its own voltage regulator 36,37,38 and the cathode of each string is connected to its own current source 40,41,42.

[0038] The voltage regulator is preferably a switching regulator, sometimes called a switch mode power supply (SMPS). Switching regulators are very efficient. One suitable type is a conventional pulse width modulated (PWM) regulator. The regulators are represented as differential ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com